- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 20, 2025 11:04 Back to list

Split Surface DTH Drilling Rig

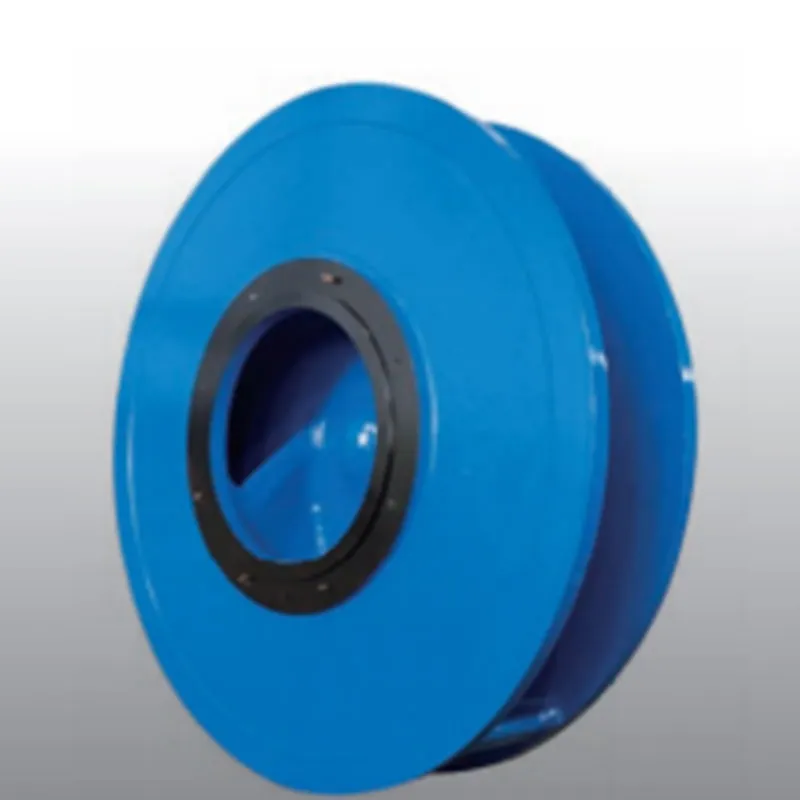

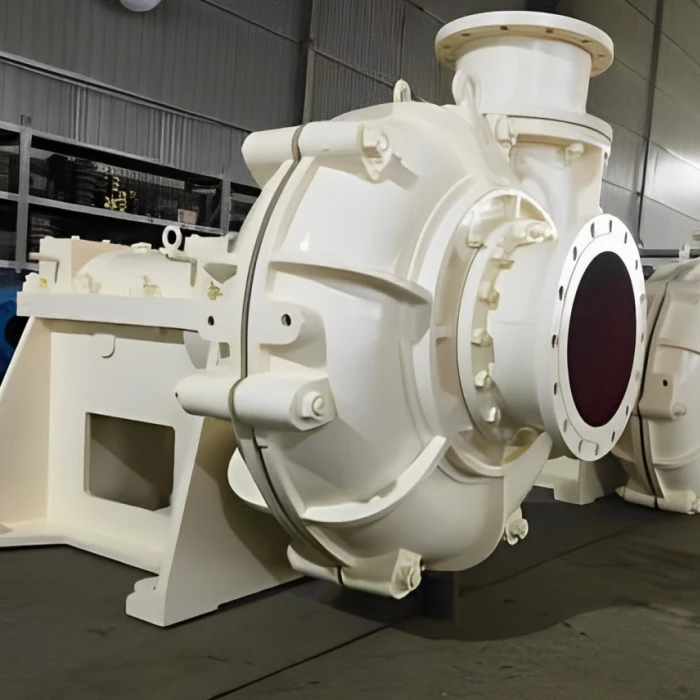

Trustworthiness in selecting wholesale metal-lined slurry pumps can be fortified by partnering with recognized manufacturers and suppliers. It's wise to look for those who comply with international standards and certifications, as these are indicators of quality and reliability. Checking customer reviews and ratings also aids in assessing the credibility of the products, ensuring that the chosen pumps meet the promised specifications and performance standards. Real-world experience suggests that well-maintained metal-lined slurry pumps have a significantly longer lifecycle compared to other materials like rubber or polyurethane. This longevity translates into cost-effectiveness, as the need for replacements and repairs diminishes over time. Maintenance practices are also simplified, often requiring standard checks and procedures due to the material's robustness. Incorporating digital monitoring tools into the operation can enhance the utility of these pumps. Many modern pumps now come equipped with sensors that monitor vibration, temperature, and flow rate in real time, providing critical data that can prevent potential failures. Investing in such technology is paramount for industries that need to maintain continuous operations without unexpected interruptions. Furthermore, while the initial cost of metal-lined slurry pumps may appear higher than other types, the investment pays off through reduced wear and tear, less frequent maintenance, and extended operational life. This aspect is a critical consideration for businesses that plan their expenses with a long-term perspective. In conclusion, metal-lined slurry pumps when sourced in bulk provide an industrial solution that combines durability, efficiency, and cost-effectiveness. Their ability to handle demanding conditions with ease makes them a preferred choice across various sectors. For businesses looking to enhance their operational efficiency and lifecycle of their equipment, investing in metal-lined slurry pumps becomes a strategic decision backed by industry expertise and real-world data. Each decision point, from the type of metal used to the credibility of the manufacturer's certifications, plays a pivotal role in ensuring these pumps exceed performance expectations.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025