- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 10, 2025 10:20 Back to list

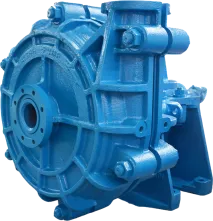

bombas de escoria en china

Authoritativeness in this domain is bolstered by stringent quality control measures aligned with international standards. Chinese manufacturers benefit from comprehensive testing facilities that simulate real-world operational conditions, ensuring that every component of a slag pump is vetted before deployment. This meticulous approach provides a foundation of trust, ensuring that both domestic and international clients can rely on the consistent performance and longevity of Chinese-made slag pumps. The trustworthiness of Chinese slag pump manufacturers is reflected in their commitment to customer service and operational support. Companies frequently offer extensive after-sales services, including maintenance training, on-site technical support, and rapid parts replacement—a critical aspect for industries where pump downtime can equate to significant financial losses. Building long-term relationships with clients through transparent communications and reliable service further strengthens market standing. Moreover, sustainability and environmental considerations are becoming integral to product development. The incorporation of eco-friendly technologies and processes in manufacturing is gradually being emphasized, as regulatory frameworks around waste management and emissions become more stringent globally. Chinese manufacturers are beginning to address these challenges, fostering greater environmental responsibility while maintaining economic efficiency. Navigating the complex landscape of slag pumps in China requires an understanding not only of the technical aspects but also of market trends and global positioning. With a foundation built on innovation, quality, and service, China's slag pump industry is set for continued growth, contributing significantly to both national and international industrial sectors. The focus on continuous improvement and adaptation to changing industry needs ensures they remain relevant and competitive, making them a formidable player in the global market.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025