- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 16, 2025 10:06 Back to list

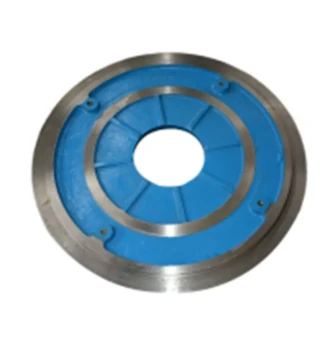

Slag Tank

Expertise in using a 3mm drill rod entails more than just selecting the right material. Understanding the appropriate drilling speed, feed rate, and cooling methods can distinguish a novice from a seasoned professional. A lower speed is typically recommended when working with metal to avoid overheating, while woodwork may demand a higher speed for clean cuts. Applying the correct pressure reduces the risk of breakage, especially with delicate operations. Coolant or lubrication also plays a pivotal role in maintaining the tool's integrity and prolonging its lifespan. Trust in a tool’s manufacturer is another aspect that cannot be overlooked. Reputable brands tend to offer detailed specification sheets, customer support, and reviews from certified users that increase a product's credibility. Consideration of user feedback and industry approval ratings can be crucial deciding factors for professionals who rely on consistency and quality in their tools. Investing in brands with a proven track record not only ensures high performance but also enhances workflow efficiency by minimizing potential tool failures. Environmental considerations are also increasingly significant. Some manufacturers are exploring sustainable production methods, a step forward in reducing the ecological footprint. Providing transparency in sourcing materials and committing to environmentally-friendly practices can strengthen a brand's credibility in a market where consumers are more aware and conscientious than ever before. In conclusion, the 3mm drill rod epitomizes the blend of engineering prowess and practical application. Its precision, complemented by superior material selection and expert handling, offers unmatched performance in diverse fields. By aligning with trusted brands and ethical manufacturing practices, users can ensure that they are equipped with a tool that not only meets but exceeds expectations. This ensures long-term satisfaction, a hallmark of quality that professionals have come to trust and depend upon in their daily endeavors.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025