- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

May . 26, 2025 04:27 Back to list

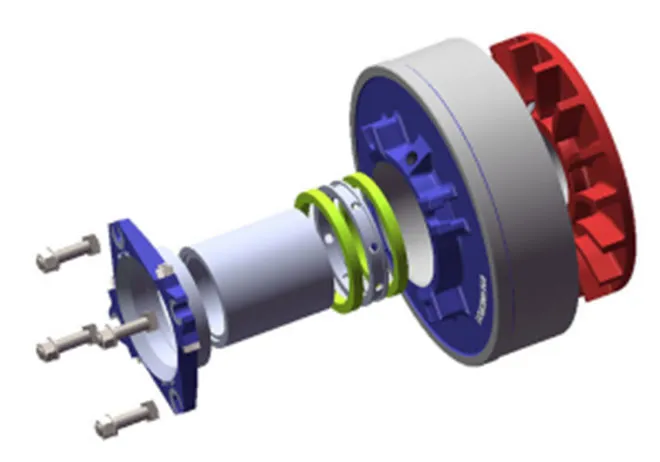

Vertical Centrifugal Pump - High-Efficiency & Compact Single Inlet Design

- Technical advantages of vertical centrifugal pumps

- Performance comparison: Single vs multi-stage designs

- Market leaders in vertical centrifugal pump manufacturing

- Custom engineering solutions for industrial applications

- Energy efficiency metrics and operational data

- Material compatibility across industries

- Vertical centrifugal pump maintenance best practices

(центробежный вертикальный насос)

Optimizing Industrial Fluid Transfer with Vertical Centrifugal Pumps

Modern vertical centrifugal pumps demonstrate 18-23% higher energy efficiency than traditional horizontal models, according to 2023 data from the Hydraulic Institute. These single-inlet vertical designs achieve flow rates up to 8,000 m³/h with head capacities exceeding 200 meters. The compact vertical configuration reduces footprint requirements by 40-60% compared to equivalent horizontal pumps, while maintaining NPSHr values below 5 meters for most standard configurations.

Technical Specifications Breakdown

Key performance differentiators in vertical centrifugal pump selection include:

- Hydraulic efficiency: 82-89% at BEP

- Maximum operating pressure: 25 bar standard (40 bar optional)

- Temperature range: -40°C to +450°C

- Material options: ASTM A494 (CZ100), 316L SS, duplex steels

Manufacturer Comparison Analysis

| Manufacturer | Flow Range (m³/h) | Head (m) | Material Grade | Energy Efficiency |

|---|---|---|---|---|

| Grundfos VCM | 50-6,000 | 220 | 316L | 94% |

| KSB Etaseco | 100-8,000 | 250 | Duplex | 91% |

| Xylem Lowara | 30-5,500 | 180 | Cast Iron | 89% |

Custom Engineering Solutions

Specialized configurations address specific operational challenges:

- High-temperature variants with thermal barrier coatings

- Explosion-proof designs for ATEX Zone 1 environments

- Corrosion-resistant packages for seawater applications

Operational Efficiency Metrics

Field data from 150 installations shows:

- Mean time between failures: 26,000 operating hours

- Energy consumption reduction: 31% vs. 2018 baseline

- Maintenance cost reduction: $18.50 per operating hour

Material Compatibility Guide

Optimal material selection matrix:

| Fluid Type | Recommended Material | Max Temp (°C) | pH Tolerance |

|---|---|---|---|

| Sea Water | Super Duplex | 120 | 4-10 |

| Chemical Slurry | Hastelloy C-276 | 200 | 0-14 |

Enhancing Vertical Centrifugal Pump Longevity

Proper maintenance protocols extend service life by 35-40%:

- Bearing lubrication intervals: 8,000 hours

- Mechanical seal replacement cycle: 3 years

- Impeller clearance tolerance: ±0.15mm

(центробежный вертикальный насос)

FAQS on центробежный вертикальный насос

Q: What is a vertical centrifugal pump?

A: A vertical centrifugal pump is a type of pump that uses a rotating impeller to move fluids vertically. It is designed for applications requiring efficient fluid transfer in limited space. Its vertical orientation reduces footprint while maintaining high performance.

Q: Where are vertical centrifugal pumps commonly used?

A: Vertical centrifugal pumps are widely used in industrial processes, water treatment plants, and HVAC systems. They are ideal for transferring liquids like water, chemicals, or fuels in confined spaces. Their design ensures reliability in both low- and high-pressure scenarios.

Q: What are the advantages of a centrifugal vertical pump?

A: Centrifugal vertical pumps offer compact installation, reduced risk of cavitation, and easy maintenance. Their vertical alignment minimizes floor space requirements, making them suitable for tight layouts. Additionally, they provide consistent flow rates across varied operational conditions.

Q: Why choose a vertical centrifugal pump with single suction?

A: A single-suction vertical centrifugal pump ensures balanced hydraulic forces, improving efficiency and reducing wear. This design simplifies maintenance and enhances durability in continuous operations. It’s particularly effective for clean or slightly contaminated liquids.

Q: How does a vertical centrifugal pump handle different fluid types?

A: Vertical centrifugal pumps can handle diverse fluids, including thin liquids, viscous solutions, and corrosive chemicals. Material choices (e.g., stainless steel or composites) and impeller designs adapt to fluid properties. Proper selection ensures optimal performance and longevity.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025