- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 28, 2025 06:04 Back to list

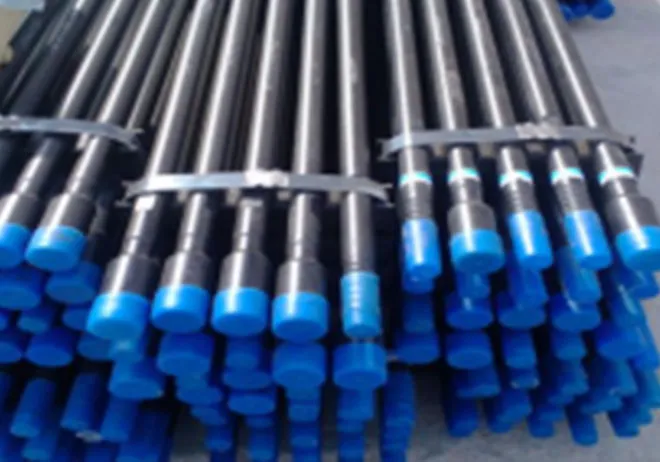

10mm drill rod

User experiences further underline the importance of choosing the right 10mm drill rod. Regular users from the mining sector frequently highlight how high-quality drill rods minimize operational disruptions and enhance productivity. A mining engineer from a leading extraction company shared how switching to a superior grade 10mm drill rod reduced their equipment downtime remarkably, translating to significant cost savings and increased output. Moreover, the choice of a 10mm drill rod can influence the outcome of construction projects. Contractors often report that substandard rods result in inaccurate drill paths, which can lead to misalignments in structural installations. This emphasizes the necessity of investing in reputable brands known for their precision engineering and consistency in meeting industry standards. The economic implications of investing in a high-quality 10mm drill rod are profound. Although the initial cost may seem higher, the durability and efficiency of a superior rod often offset these costs by reducing the need for frequent replacements and repairs. Cost analysis conducted by industry experts reveals that the long-term savings from enhanced performance and lower maintenance far outweigh the upfront expenditure. Ultimately, the decision to select a particular 10mm drill rod should be informed by a combination of technical specifications, brand reputation, and peer reviews. Seasoned professionals advocate for thorough research, including consulting product reviews and industry publications that offer unbiased evaluations of various drill rod brands and models. In conclusion, the 10mm drill rod, with its precise engineering and robust material composition, stands as an epitome of reliability and efficiency. Its role in ensuring the success of critical drilling operations cannot be overstated. By understanding the intricate details that contribute to its performance—material quality, design innovation, compliance with safety standards—it becomes easier for engineers and contractors to make informed decisions, leading to successful and safe project executions.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025