- The use of HPMC in construction also contributes to sustainability

- In addition to providing essential nutrients, VAE powder is also known for its antioxidant properties. Antioxidants help protect the body from damage caused by free radicals, which are unstable molecules that can contribute to aging and disease. By consuming VAE powder regularly, you can help support your body's natural defense system and promote overall health.

- HPMC capsules are not enteric-coated, which means that they dissolve in the stomach and release the ingredients.

Although enteric-coated capsules can also be made from HPMC, they are also coated with synthetic substances that can withstand stomach acid. The idea behind such capsules is that they dissolve in the small or large intestine and release the ingredients there. This is useful if, for example, the acidic environment of the stomach would destroy the active ingredients. However, the intake of such capsules should always be discussed with the treating doctor, as the application must be carefully observed.

You may report side effects to the FDA at 1-800-332-1088. You may also report side effects at https://www.fda.gov/medwatch.

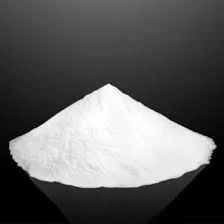

Answer:1) whiteness: although whiteness can not determine whether HPMC is good, and if it is added in the production process of whitener, will affect its quality. However, good products are mostly white.

2) Fineness: HPMC fineness generally has 80 mesh and 100 mesh, 120 purpose is less, the finer the fineness is generally better.

3) transmittance: the hydroxypropyl methyl cellulose (HPMC) into the water, the formation of transparent colloid, see its transmittance, the greater the transmittance, the better, that less insoluble matter inside.

4) Proportion: the larger the proportion is better. It's usually because it's high in hydroxypropyl,

High hydroxypropyl content, water retention is better.