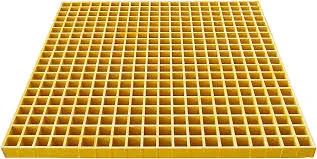

Fiberglass grating options are essential for a wide scale of projects and types of construction. So this material is often used throughout many types of industries.

In applications where the grating may need more support than that offered by the molded in recesses at the top of the flume, Openchannelfow installes tube supports at the inlet / outlet of the flume for the grating to sit on to provide additional support.

Chemical Processing: Used in chemical plants and refineries due to its corrosion resistant and slip resistant properties.

Gratings & Covers

In addition to its cost and maintenance benefits, fiberglass grating is slip-resistant which makes it a safer option when compared to metal gratings or other types of flooring materials that have a lower friction factor, especially in wet or oily environments. It also has excellent fire resistance properties, with some specialty grating withstanding short-term temperature exposures up to 1700°F. This fire resistance makes it suitable for use in areas where there may be a risk of fire or excessive heat exposure such as industrial manufacturing plants, power plants, or offshore oil platforms.

Gratings & Covers

Construction: Used for flooring, platforms, and stair treads in commercial and industrial buildings.