А2 буровой штанг

Manufacturers also rely on these compressors for various processes, including sandblasting, spray painting, and pneumatic conveying

. The dynamic requirements of manufacturing plants often necessitate reliable equipment that can keep up with high output demands, making the 185 CFM compressor a popular choice.

venda de compressores de parafuso diesel

The Slurry Pump Blade Factory prides itself on its commitment to innovation and quality engineering. Utilizing state-of-the-art manufacturing techniques, the factory produces blades that not only improve the pump's efficiency but also enhance its lifespan. This commitment is driven by a team of experienced engineers and technicians who continually research and develop new designs tailored to meet the ever-evolving demands of the industry.

Equipment and Technology

Submarine hammer drilling sees extensive applications in several sectors

2. Applications:

Progressive cavity pump slurries are commonly used in industries such as wastewater treatment, oil and gas, mining, and food processing. They are known for their ability to handle abrasive and corrosive materials, making them versatile and reliable in various settings.

2. Applications:

Progressive cavity pump slurries are commonly used in industries such as wastewater treatment, oil and gas, mining, and food processing. They are known for their ability to handle abrasive and corrosive materials, making them versatile and reliable in various settings.

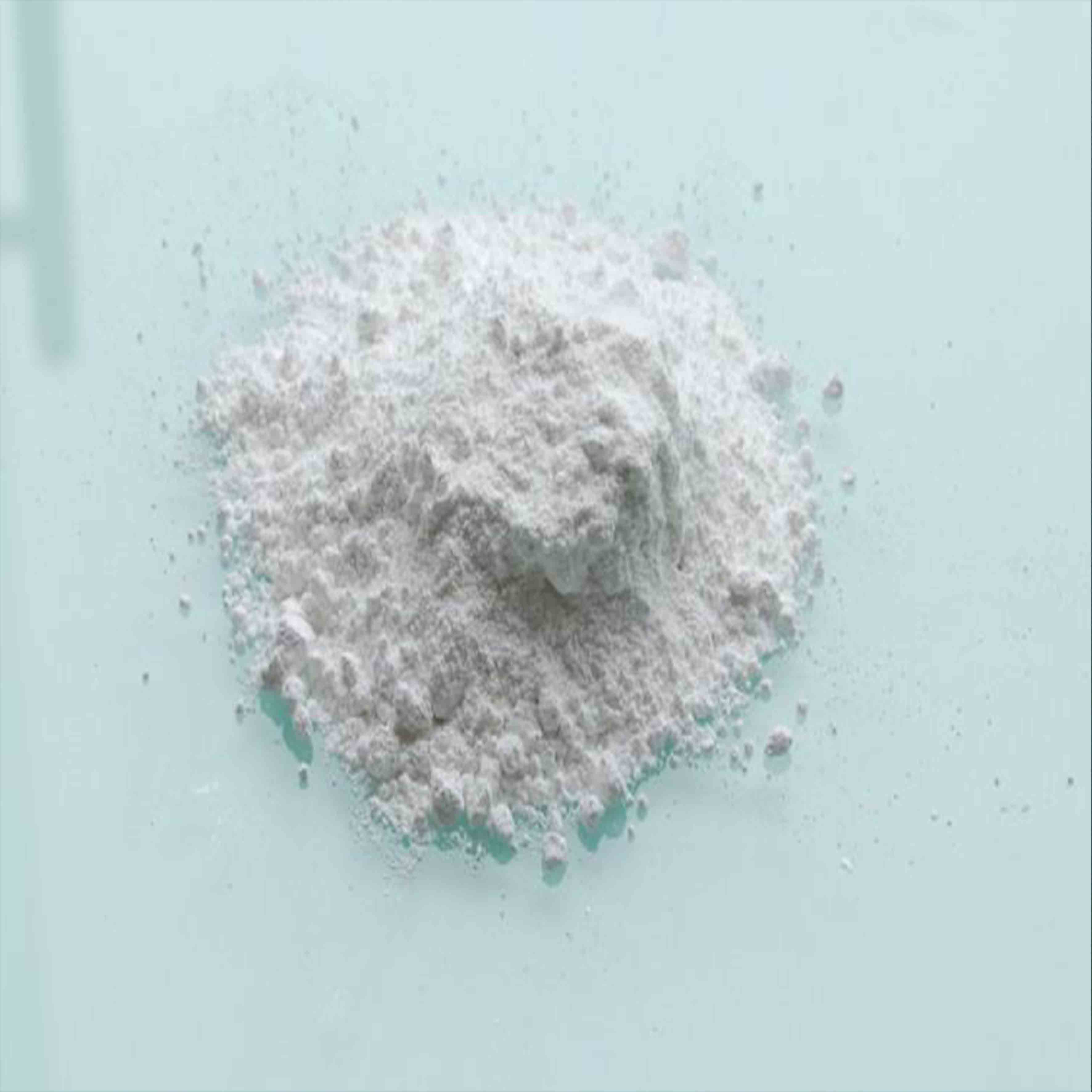

Additionally, efforts are being made to develop eco-friendly manufacturing methods, such as recycling TIO2 waste and utilizing renewable energy sources Additionally, efforts are being made to develop eco-friendly manufacturing methods, such as recycling TIO2 waste and utilizing renewable energy sources

Additionally, efforts are being made to develop eco-friendly manufacturing methods, such as recycling TIO2 waste and utilizing renewable energy sources Additionally, efforts are being made to develop eco-friendly manufacturing methods, such as recycling TIO2 waste and utilizing renewable energy sources When dispersed properly within the polymer matrix, TiO2 particles can reinforce the material, improving its tensile strength and impact resistance When dispersed properly within the polymer matrix, TiO2 particles can reinforce the material, improving its tensile strength and impact resistance

When dispersed properly within the polymer matrix, TiO2 particles can reinforce the material, improving its tensile strength and impact resistance When dispersed properly within the polymer matrix, TiO2 particles can reinforce the material, improving its tensile strength and impact resistance

It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality

It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality