3 16 drill rod

1. Construction Sites Commonly used to power tools like jackhammers, air nailers, and other pneumatic equipment essential for construction projects.

- Diamond Bits These are designed for drilling through hard rock and are often employed in geological explorations.

Slurry pumping is an essential process in various industrial sectors including mining, construction, and wastewater treatment. A slurry is a mixture of solid particles and liquid, which can vary widely in properties, making the choice of pump critical for efficiency and effectiveness. In this article, we will explore the types of pumps used for slurry applications, their working principles, and the factors to consider when selecting the right pump.

Regular replacement of wear-prone parts like drill bits and filters is an indispensable part of maintenance work. Establishing a reasonable replacement schedule based on usage frequency and working conditions can effectively prevent failures, ensuring the continuity and efficiency of operations.

In the ever-evolving fields of mining and construction, the need for efficient, precise, and powerful drilling techniques is paramount. Among various methods, down-the-hole (DTH) hammer drilling has emerged as a pivotal technology, providing a range of benefits that enhance productivity and reduce operational costs.

1. Offshore Oil and Gas Exploration In the oil and gas industry, submarine hammer drilling is crucial for the installation of subsea pipelines and wellheads. The ability to efficiently penetrate the seabed allows for the secure placement of infrastructure that can transport hydrocarbons from extraction points to processing facilities.

Self-priming slurry pump solutions are engineered to deliver optimal performance in challenging environments. Their advanced features and capabilities empower industries to operate more efficiently and effectively, driving productivity and profitability.

Self-priming slurry pump solutions are engineered to deliver optimal performance in challenging environments. Their advanced features and capabilities empower industries to operate more efficiently and effectively, driving productivity and profitability.

Conclusion

Mining Industry

Mining Industry

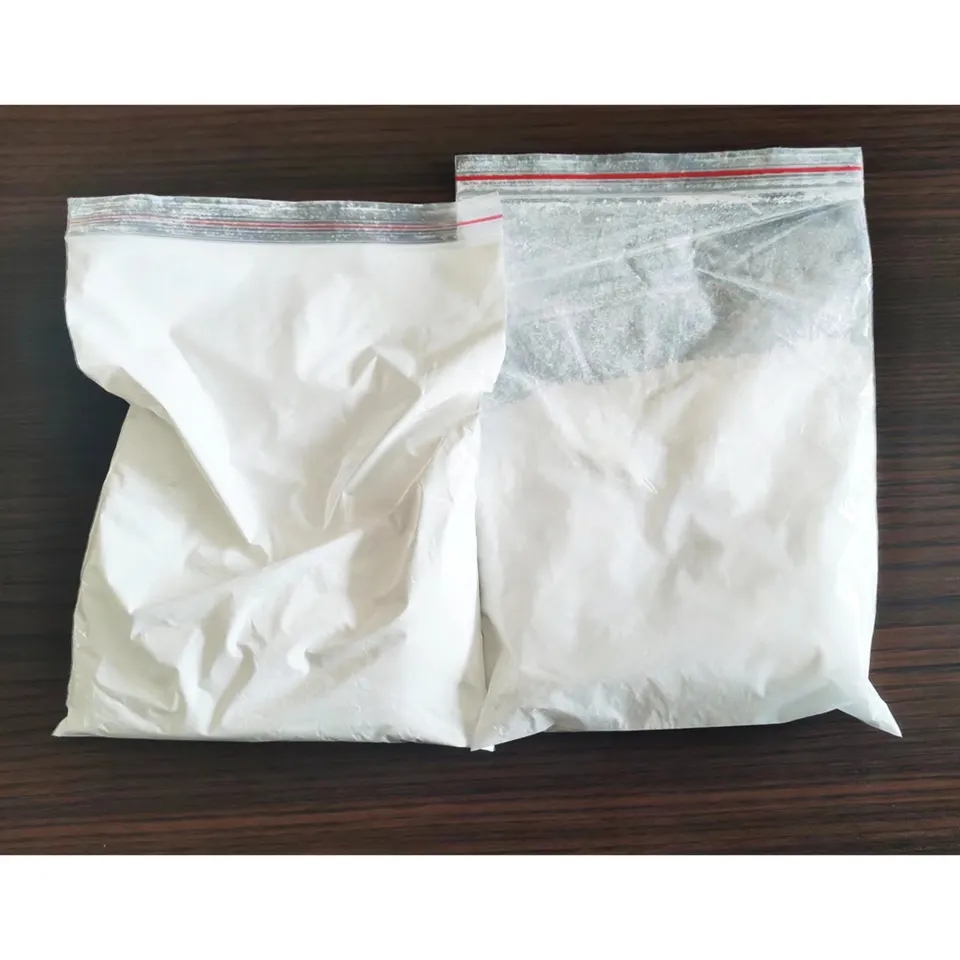

In addition, rutile is also used in the manufacturing of electronic devices, such as capacitors and transistors, due to its high electrical conductivity In addition, rutile is also used in the manufacturing of electronic devices, such as capacitors and transistors, due to its high electrical conductivity

In addition, rutile is also used in the manufacturing of electronic devices, such as capacitors and transistors, due to its high electrical conductivity In addition, rutile is also used in the manufacturing of electronic devices, such as capacitors and transistors, due to its high electrical conductivity

They must adhere to stringent production standards to guarantee the purity and performance characteristics required by diverse applications They must adhere to stringent production standards to guarantee the purity and performance characteristics required by diverse applications

They must adhere to stringent production standards to guarantee the purity and performance characteristics required by diverse applications They must adhere to stringent production standards to guarantee the purity and performance characteristics required by diverse applications