Conclusion

...

2025-08-15 06:12

1479

Conclusion

Downhole Drilling Equipment An Overview

(5) The inspection of hydraulic components can only be prevented under the condition of pole cleaning, and after the connecting tissue is removed, it must be quickly plugged with the cleaning tightly matched plug. Before the repaired rock drill is used from scratch, it is necessary to circulate the hydraulic oil into the oil circuit to wash the components of the hydraulic system.

Applications of DTH Hammer Drilling

Furthermore, advancements in technology, including the development of automated drilling systems and real-time data analytics, are refining the performance of directed drilling rods. These technologies allow for better decision-making during the drilling process, enhancing operational efficiency and reducing costs.

Whether in mining, construction, or waste management, the ZJ slurry pump proves to be more than just a piece of machinery—it is a cornerstone of operational excellence in an increasingly competitive industrial landscape.

One of the key drivers of this growth is technological advancement. The emergence of automated and remotely operated drilling rigs has revolutionized the industry. These advanced machines are not only more efficient but also enhance safety by minimizing human exposure to hazardous working conditions. Furthermore, innovations such as real-time data analysis and predictive maintenance have improved operational efficiency, allowing businesses to optimize their drilling operations and reduce downtime.

3. Open-air drilling rig: according to the different working mechanism of crushing ore and rock, it is divided into steel rope percussion drill, drilling rig, cone drill and rotary drill. Because of low efficiency, the steel rope percussion drill has been gradually replaced by other drilling RIGS. The drill pipe drives the pneumatic impactor and the drill bit to rotate together, and the piston of the pneumatic impactor is used to impact the drill bit to break the ore and rock, which is usually used in small and medium-sized mines to drill holes with a diameter of 80 to 250 mm.

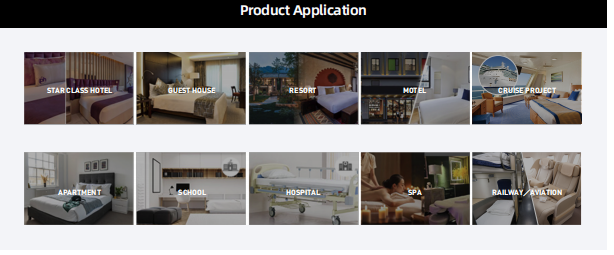

What is the history of bed linen?

The combination of high thread count, premium fabrics, and durable construction make hotel sheets a hallmark of the guest experience. Attention to detail and a focus on providing the ultimate in comfort and luxury set hotel bedding apart, ensuring guests enjoy a restful and rejuvenating sleep during their stay. Whether they feel smooth against your skin or look crisp and fresh, hotel sheets are an important element of the overall hotel experience.

custom made luxury bedding. The size and shape can also be tailored to fit unconventional bed sizes or accommodate specific requirements. Pillow inserts can be customized for firmness, while mattress toppers can be made to provide additional support.

custom made luxury bedding. The size and shape can also be tailored to fit unconventional bed sizes or accommodate specific requirements. Pillow inserts can be customized for firmness, while mattress toppers can be made to provide additional support.Each component in your bedding, from the bed sheet to the broader bed linens, has a specific function and usage that contributes to your overall sleep experience.

A well-coordinated towel ensemble can elevate the bathroom's visual appeal, contributing to a luxurious and cohesive design A well-coordinated towel ensemble can elevate the bathroom's visual appeal, contributing to a luxurious and cohesive design

A well-coordinated towel ensemble can elevate the bathroom's visual appeal, contributing to a luxurious and cohesive design A well-coordinated towel ensemble can elevate the bathroom's visual appeal, contributing to a luxurious and cohesive design hotel type towels.

hotel type towels. Their colorfastness adds an extra touch of richness, ensuring vibrant hues that stay true over time Their colorfastness adds an extra touch of richness, ensuring vibrant hues that stay true over time

Their colorfastness adds an extra touch of richness, ensuring vibrant hues that stay true over time Their colorfastness adds an extra touch of richness, ensuring vibrant hues that stay true over time hotel collection 1800 thread count.

hotel collection 1800 thread count.