4. Cosmetics and Personal Care HPMC is also prevalent in the cosmetics and personal care industries due to its film-forming and emulsifying properties. It is found in products such as lotions, shampoos, and creams, where it helps to stabilize formulations and improve the overall texture.

Allergic Reactions

Redispersible Polymer Powder (RDP) has become an essential component in the construction and building materials industry. It is a versatile product that, when mixed with water, forms a film that enhances performance characteristics in various applications, including tile adhesives, sealants, and external wall systems. Understanding the properties, benefits, and applications of RDP can help professionals make informed choices about their material selections.

Understanding Redispersible Polymer Powder and Its HS Code

Conclusion

In summary, HPMC's unique properties make it an invaluable asset in the manufacturing and application of gypsum materials, contributing to safer, more efficient, and higher-quality construction practices. As awareness of its benefits grows, HPMC will undoubtedly remain a staple in the development of gypsum-based solutions.

Applications

3. Analyze Lab Reports Many suppliers offer lab reports verifying the quality and specifications of their HPMC. These can provide crucial insights into the product you intend to buy.

1. Thickening Ability One of the primary functions of HPMC is its ability to increase the viscosity of solutions. This makes it an ideal choice for formulations requiring stable suspension or gel-like consistency.

Understanding HPMC

Insulation system: In the external wall insulation system, redispersible powder is also widely used. It can improve the bonding strength and compressive strength of insulation materials, thereby ensuring the stability and durability of the insulation system.

In an ever-evolving business landscape, organizations constantly seek innovative solutions that cater to their specific needs. HPMC Solutions LLC has emerged as a key player in this sphere, providing tailored strategies and services designed to help businesses thrive in the competitive market. With a motto of enhancing operational efficiency and driving growth, HPMC Solutions LLC stands out as a beacon for companies looking to streamline their processes and enhance their performance.

Hydroxypropyl methyl cellulose (HPMC) is a versatile chemical compound derived from cellulose, a natural polymer from plant cell walls. The production of HPMC is a sophisticated process that utilizes advanced methodologies in the cellulose derivatization process. This compound has garnered attention across numerous industries due to its unique properties, including its ability to form gels, retain moisture, and act as a thickening and binding agent.

Cell Size Influences on HEC Applications

cellosize hec

The Relevance of HPMC in Various Industries

5.Application of redispersible polymer powder

Redispersible polymer powders have a wide range of applications in the construction industry, where they are used to formulate a variety of products:

Though rare, allergic reactions to HPMC can occur. The symptoms may vary from mild to severe and might include rashes, itching, and respiratory issues. Individuals with a known allergy to cellulose or its derivatives should exercise caution when using products containing HPMC. It is advisable for those susceptible to allergies to consult a healthcare professional before using HPMC-containing products.

Balancing Resolution and Computational Efficiency

2. Product Range A good supplier will offer a variety of HEC grades tailored for specific applications. This allows customers to choose the right product for their needs, whether they require high viscosity, low viscosity, or specialized formulations.

Applications

The Impact of Innovation

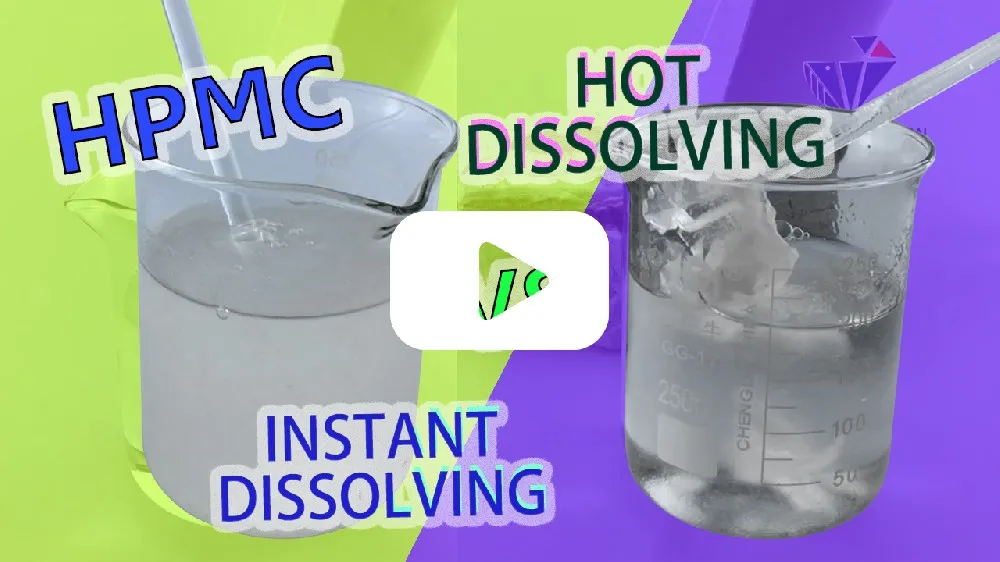

Importance of HPMC Dispersion

The cosmetic industry in China is also leveraging HPMC for its thickening and emulsifying properties. It is commonly found in skincare and haircare products, providing a smooth application and enhancing product stability. With the increasing interest in cosmetic formulations that are effective and safe, HPMC provides an ideal solution for formulators seeking to develop innovative products that cater to discerning consumers.

4. Geopolitical Factors Global events, including trade policies, tariffs, and international relations, can have a profound effect on market prices. For example, if a major supplier of cellulose faces trade restrictions, the global supply of HPMC may diminish, resulting in increased prices. Additionally, economic sanctions or conflicts can disrupt production lines and shipping routes, leading to price volatility.

In the realm of modern construction, the importance of effective bonding agents cannot be overstated. Mortar adhesive additives are critical components in the formulation of mortar, which is widely used in masonry and tile applications. Understanding the role and benefits of these additives can significantly enhance the performance of construction materials, leading to increased durability, improved adhesion, and overall project longevity.

Viscosity and Use Cases

Properties of HPMC 4000 CPS

Moreover, some bonding additives improve the workability of the mortar mixture. This is especially important on construction sites where time is of the essence. A more workable mix allows for easier application and manipulation, reducing labor time and improving overall efficiency. Tradespeople can achieve smoother applications, which ultimately leads to a more aesthetically pleasing finish. This ease of application is crucial in complex projects or intricate designs where detailed work is required.

mortar bonding additive

Potential Concerns and Considerations

In addition to its abundant resources and community-focused features, the HPMC website leverages technology to enhance user experience. Tools such as interactive symptom checkers, medication databases, and personalized health assessments are readily available. These innovative features not only assist healthcare professionals in their practice but also empower patients to actively participate in their own healthcare journey.

MHEC is characterized by its unique chemical structure, which enables it to dissolve easily in water, forming a stable, viscous solution. The degree of substitution, which denotes the number of hydroxyl groups substituted by methyl and hydroxyethyl groups, plays a crucial role in determining its solubility and viscosity. MHEC can be tailored to meet specific requirements, making it an indispensable ingredient in formulations that require thickening, binding, or emulsification.

Hydroxypropyl Methyl Cellulose (HPMC) is a versatile cellulose ether that has garnered significant attention across various industries, including pharmaceuticals, food, construction, and personal care. As a supplier of this essential compound, HPMC manufacturers play a vital role in facilitating the production of products that millions of people rely on daily.

The HS code for Hydroxypropyl Methylcellulose falls under the broader category of polysaccharides and derivatives. Generally, HPMC is classified under HS Code 3912, which pertains specifically to “Cellulosic and cellulose derivatives.” However, the precise classification may vary slightly depending on regional interpretations and additional modifications of the substance. It is crucial for manufacturers and exporters to consult local customs authorities or trade experts to ensure compliance with the correct HS code and avoid potential issues during the shipping process.

- Inquire About Technical Support When buying from a manufacturer or supplier, ask if they provide technical support or consultation. This can be invaluable, especially if you are using HEC for a specialized application.

7. Consider pH Levels and Other Additives The solubility of HEC can be affected by the pH of the solution. If you are formulating a product that includes other ingredients, ensure that they do not adversely affect the pH and, consequently, the solubility of HEC.

Understanding HPMC Viscosity and Its Applications

How to Dissolve Hydroxyethyl Cellulose

2. Filler Additives These are materials that improve the density and workability of cement mixtures. They can also enhance the adhesive properties by filling voids within the mix, thereby providing a more solid structure once cured.

cement adhesive additive

Hydroxyethyl Cellulose Solubility in Water

Hydroxypropyl methylcellulose is a versatile compound with a wide range of applications across various industries. While it is generally considered safe, potential side effects such as gastrointestinal discomfort, allergic reactions, and interactions with medications warrant attention. Understanding these side effects can help consumers make informed decisions regarding HPMC-containing products. As with any food additive or therapeutic agent, moderation and consultation with healthcare professionals are key to ensuring safety and efficacy. If any adverse reactions occur, seeking medical advice is vital for appropriate management and care.

Understanding HPMC and Its Role in SDS A Comprehensive Overview

Applications of HPMC

HPMC also serves as a soil release agent, particularly in laundry detergents. Fabrics often harbor soil and stains that can be difficult to remove during washing. HPMC reduces the surface tension of water, allowing it to penetrate fabrics more easily. This property aids in loosening up dirt and grime from the fibers of clothing, making it easier for detergents to lift and wash away stubborn stains. The effective soil release action leads to cleaner fabrics and improved wash performance.

RDP is used in gypsum-based products such as joint compound and stucco to enhance their adhesion, workability and resistance to cracking.

Various additives, such as dispersants, anti-caking agents, and protective colloids, are often added to improve the stability and handling of the powder.