- Strictly control of the surface finish, few scratches.

- Aluminum profiles for doors and windows are a popular choice for homeowners and builders alike. These versatile materials offer numerous benefits that make them an excellent option for construction projects.

- The traditional sliding door roller system often suffers from wear and tear, leading to uneven movement and potential jamming. However, the new roller for sliding doors is designed with cutting-edge technology to address these issues. It features a durable material that can withstand the test of time, ensuring smooth operation for years to come.

- Next, remove the screen door from the track by lifting it up and tilting it out. Place the door on a flat surface with the roller facing up. Use a screwdriver to remove the screws that hold the roller in place. Once the screws are removed, carefully slide the roller out of the door.

- Don't forget to inquire about after-sales services such as installation assistance and warranty coverage. A good supplier should stand behind their products and offer support throughout the process.

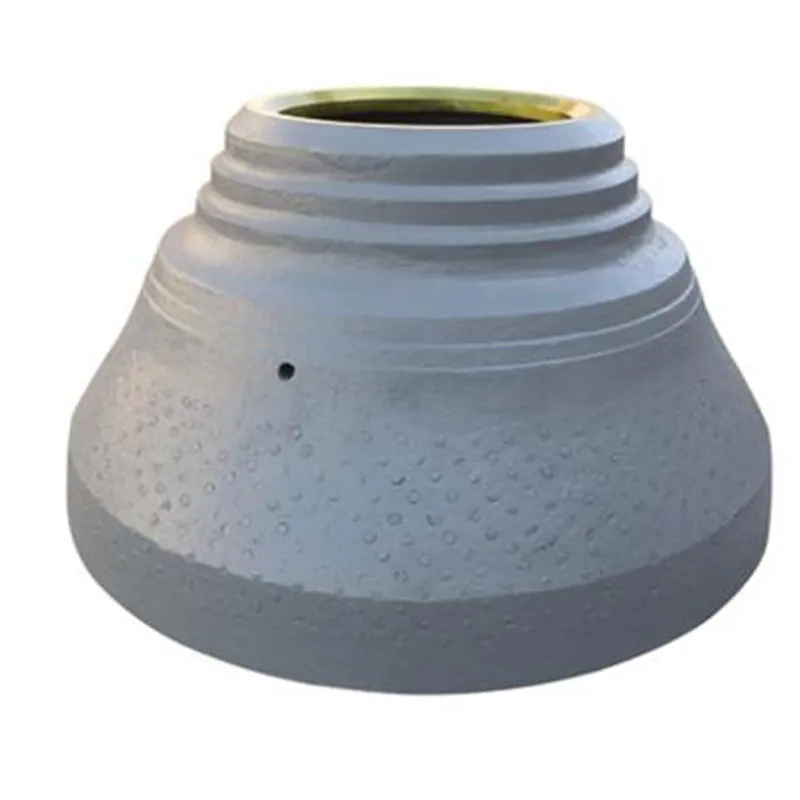

- Quality premium material

Wrought iron’s density and weight make it a valuable recycling material. Prices for scrap metal fluctuate, so check current rates and consider selling the iron when prices are favorable to maximize your return.

- Another advantage of cast iron ornaments is their versatility. They can be used in a variety of settings, from traditional homes to contemporary spaces. Their classic design makes them a perfect fit for any decor style, from rustic to elegant. Whether you prefer a simple, minimalist look or a more ornate, detailed design, there is a cast iron ornament that will complement your home's aesthetic.

They are pretty several and have become more popular among different users all over the world nowadays.

Molten iron is poured into molds, each one carefully crafted to create the desired pattern Molten iron is poured into molds, each one carefully crafted to create the desired pattern

Molten iron is poured into molds, each one carefully crafted to create the desired pattern Molten iron is poured into molds, each one carefully crafted to create the desired pattern cast iron decorative panels. Once cooled and solidified, the panels emerge with a level of detail that is unparalleled. The resulting product is a piece of art that is both functional and visually stunning.

cast iron decorative panels. Once cooled and solidified, the panels emerge with a level of detail that is unparalleled. The resulting product is a piece of art that is both functional and visually stunning.Common Applications

cast iron components. They maintain their shape under stress, ensuring precision in mechanical operations. Agricultural equipment, mining machinery, and power generation systems all incorporate cast iron parts for reliable performance.

cast iron components. They maintain their shape under stress, ensuring precision in mechanical operations. Agricultural equipment, mining machinery, and power generation systems all incorporate cast iron parts for reliable performance. fly screen door rollers. A well-functioning screen door not only keeps bugs out, but it also adds to the aesthetic appeal of your home. A fly screen door roller helps to ensure that your screen door operates smoothly and quietly, adding to the overall comfort and elegance of your home.

fly screen door rollers. A well-functioning screen door not only keeps bugs out, but it also adds to the aesthetic appeal of your home. A fly screen door roller helps to ensure that your screen door operates smoothly and quietly, adding to the overall comfort and elegance of your home.Anodised Aluminium Profiles

adjusting pocket door rollers. Make small adjustments, testing the door after each turn to ensure it slides smoothly. It may take a few tries to get the door to the desired height, so be patient and continue to make small adjustments as needed.

The melted material is then poured into a mold (i.e. a “cast”) with a predetermined shape and allowed to cool. Cast iron structures can be as simple or intricate as the mold they were poured into, and the fact that the iron solidified all in one continuous piece helps make these structures extremely sturdy.

Additionally, rollers can be made from different materials, including nylon, metal, and composite materials. Nylon rollers are popular due to their quiet operation and resistance to corrosion. Metal rollers, on the other hand, provide increased durability, making them ideal for heavier windows.

rollers for aluminum sliding windows

ITEM #2 – HOW IS IT CONSTRUCTED?

wrought iron manufacturers. This finish can be painted, powder-coated, or left bare, depending on the desired aesthetic.

Easy Alloying

These boxes are equipped with high-quality locks that provide excellent protection against theft and unauthorized access These boxes are equipped with high-quality locks that provide excellent protection against theft and unauthorized access

These boxes are equipped with high-quality locks that provide excellent protection against theft and unauthorized access These boxes are equipped with high-quality locks that provide excellent protection against theft and unauthorized access stainless steel lock box. Many models also feature additional security features, such as reinforced doors and compartments, to further enhance their protective capabilities.

stainless steel lock box. Many models also feature additional security features, such as reinforced doors and compartments, to further enhance their protective capabilities.Finally, the gate is a crucial part of any fence. Without one, there is obviously no way to access the pool area you’ve secured. A wrought iron pool gate will be 4 to 5 feet wide and made to match the height of its surrounding fence. To maintain uniformity, iron gates feature the same design as the fence’s panels with many of the same dimensions: 1-inch square railings, pickets sized according to the fence, and a 4-inch spacing.

As mentioned above, wrought iron is the stronger, more durable material because the hand-forging process develops a tough, almost wood-like grain in the iron which allows it to withstand significant pressure.

Tools and Materials Needed

liatinová okrasa . The secretions contain enzymes that help to break down dead skin cells and promote the growth of new, healthy cells, leading to a smoother and more radiant complexion.

liatinová okrasa . The secretions contain enzymes that help to break down dead skin cells and promote the growth of new, healthy cells, leading to a smoother and more radiant complexion.