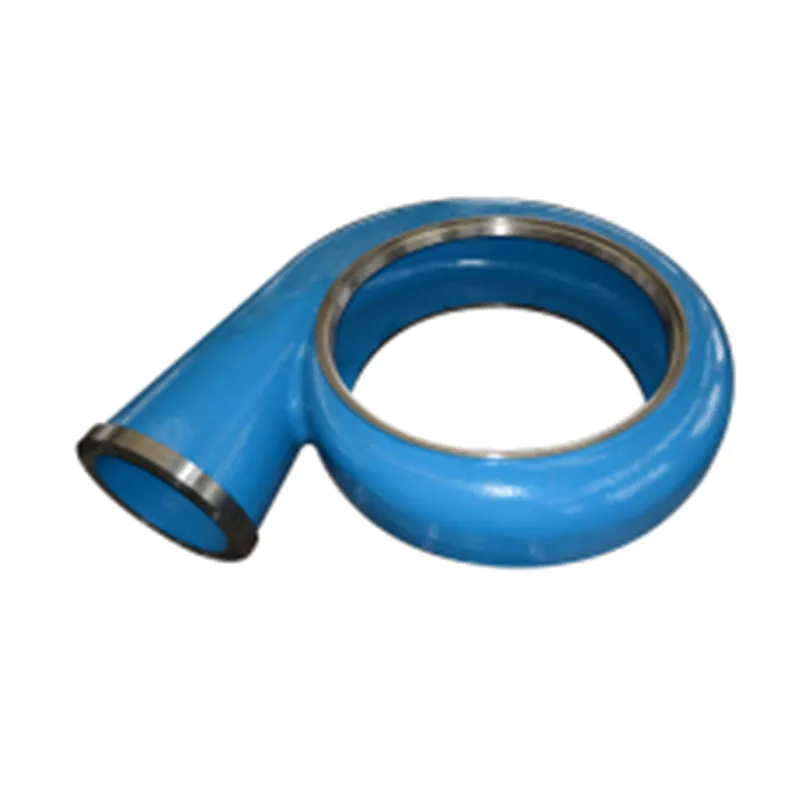

cálculo del diseño de la bomba de escoria

In the contemporary landscape of industrial tools, portable rotary air compressors are gaining unparalleled traction among professionals and enthusiasts alike. Known for their efficiency and versatility, these machines have revolutionized various sectors, including construction, automotive repair, and DIY projects. This article explores the rising demand for portable rotary air compressors, their core features, benefits, applications, and the future of this essential equipment.

Building Strong Partnerships

Understanding Down-the-Hole Hammer Drilling

Advantages of DTH Drilling Rigs

Understanding Directed Drilling Rods

The Growing Market

In automotive repair shops, 185 CFM air compressors are essential for operating impact wrenches, tire changers, and paint sprayers. Their ability to deliver compressed air continuously allows mechanics to work effectively and enhances productivity without the need for frequent breaks to recharge the system.

1. Efficiency and Productivity The high CFM output of 185% compressors ensures that multiple tools can be used simultaneously without loss of air pressure. This capability significantly increases productivity on construction sites, allowing teams to complete tasks faster and more efficiently.

Increased efficiency and productivity

- Reduced downtime and maintenance costs

- Enhanced performance in challenging environments

Increased efficiency and productivity

- Reduced downtime and maintenance costs

- Enhanced performance in challenging environments