To get the most out of sewing machine quilt patterns, mastering key techniques is vital. Here are a few essential tips

Another significant benefit is the connection to tradition that manual machines provide. With each turn of the crank, artisans engage with the history of leatherworking, honoring the craftsmanship of generations before them. This connection can be incredibly fulfilling and serves as an inspiration to many crafters.

- When selecting an industrial chain stitch machine, it is important to consider the specific needs of your business. Factors to consider include the type of fabric you will be working with, the volume of production, and the complexity of the stitching required. It is also important to choose a machine from a reputable manufacturer that offers a warranty and customer support.

Sewing machines have come a long way since their inception in the 19th century, evolving into essential tools for both hobbyists and professionals alike. Among these, the heavy duty basic sewing machine stands out for its robustness and versatility. This article will delve into the features, benefits, and uses of heavy duty sewing machines, spotlighting why they are an indispensable asset in today’s crafting world.

In the realm of upholstery, the hand sewing machine is indispensable. Unlike its industrial counterparts, a hand sewing machine provides the precision and control necessary for intricate work. Upholsters often face unique challenges such as sewing through thick fabric layers, adjusting tension, and making detailed stitch patterns. Hand sewing machines are designed specifically for this purpose, enabling craftsmen to tackle a variety of materials—from delicate silk to heavy-duty canvas—while ensuring a professional finish.

One of the standout features of the coverstitch machine is its ability to create a variety of stitch widths and types. This adaptability means that sewists can move beyond standard hems, using the machine to embellish edges or create unique design elements, such as decorative stitching along seams. As a result, the coverstitch machine is an indispensable tool for anyone looking to produce high-quality, professional-grade apparel.

6. Apron

8. Price Finally, set a budget. Computerized sewing machines can range from a few hundred to over a thousand dollars. Identify your needs and find a machine that offers the best value for your money.

Conclusion

Selecting the appropriate presser foot depends on the type of project you are working on. Understanding the function of each foot can save you time and frustration, leading to better results. Moreover, many sewing machines come with bonus feet, often bundled with the machine or available as part of a kit. Familiarizing yourself with these attachments can inspire creativity and allow you to explore new sewing techniques.

Factors Influencing Price

4. Robust Build Industrial sergers are built for heavy-duty use, often featuring metal components that withstand the rigors of daily operation in a factory. This durability translates to longer lifespans and reduced maintenance needs.

industrial serger machines

In the realm of textile production and crafting, industrial sewing machines play an indispensable role. Among the myriad of options available, the zig zag industrial sewing machine stands out as a versatile tool that caters to a range of sewing needs. Whether you are engaged in garment manufacturing, upholstery, or crafting specialized items, investing in a zig zag sewing machine can greatly enhance your productivity and the quality of your work.

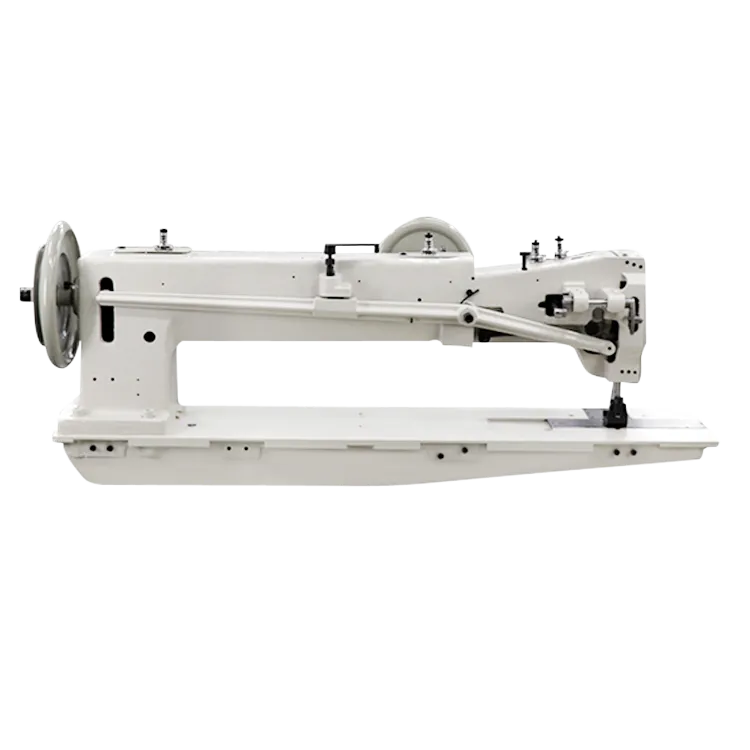

A post bed pattern sewing machine for leather is an essential tool for those who work with leather crafting and sewing. This type of sewing machine is specifically designed to handle the unique needs of working with leather materials. In this article, we will delve into the key features and benefits of a post bed pattern sewing machine for leather.

Serger machines offer a range of stitching options that traditional sewing machines do not. Beyond basic overlocking, users can create rolled hems, which are particularly useful for lightweight fabrics, and flatlock stitches, which are great for joining seams. Many sergers also have the capability to perform coverstitching, which is often used in the hems of T-shirts and activewear. This versatility allows sewists to tackle various projects, from simple alterations to complex garments.

B. Key Features to Look for:

We’ll discuss essential features to look for in a heavy duty sewing machine, such as a powerful motor, adjustable presser foot pressure, a variety of stitch options, and easy threading mechanisms. This section will help readers understand the functionalities they should prioritize while exploring different machine models.

Solution: Matching the thread type and weight to the fabric used is essential. Opt for finer threads that can pass through the material without causing strain for light fabrics. Threads like cotton, silk, or fine polyester are ideal choices. Additionally, ensure the machine’s tension settings are adjusted to accommodate the chosen thread and fabric combination.

The Evolution of Leather Sewing Machines

When you use a heavy duty industrial walking foot sewing machine- it comes with a built-in walking foot mechanism. This is very different that most walking foot attachments that only snap-on regular household sewing machines.

What Does an Overlocker Do?

The Cub Leather Sewing Machine A Tailored Solution for Leather Enthusiasts

Size and Portability

3. Regular Maintenance Implementing a strict maintenance schedule can prevent costly breakdowns and ensure that machines always operate at optimal efficiency, thereby reducing per-hour costs.

Furthermore, it features an automatic needle threader, which simplifies preparation and minimizes frustration. The included walking foot also aids in evenly feeding layers of leather, allowing for consistent stitch alignment. This focus on ease of use ensures that leatherworkers can concentrate on their creativity rather than getting bogged down by technical difficulties.

the cub leather sewing machine

Another key feature to consider is the stitch variety. Many modern walking foot machines come with advanced stitching options, enabling users to experiment with decorative stitches and quilting patterns. A machine with a large throat space is also desirable, as it provides ample room for maneuvering larger projects like quilts.

2. Even Feed When working with multiple layers, a walking foot ensures that all layers are fed through the machine evenly, preventing uneven seams and puckering. This consistency is crucial in leather crafting, where the look and finish of seams can significantly impact the overall quality of the piece.

1. Ease of Use Look for a machine that has an intuitive interface, such as a touchscreen or easy-to-navigate controls. This can significantly reduce the learning curve for beginners.

Products made of leather, such as chic handbags, classic leather jackets wallets, and belts, are not typical fabrics. They’re thick and tough, making stitching through them challenging. Also, with leather, it’s there forever. Once you make a hole, it’s there forever, so you need to get the stitch right from the start. That’s where heavy-duty sewing machines come into play. With extra power and consistent pressure, they ensure the needle penetrates the leather smoothly and evenly so using suitable needles for leather, is also essential.

A double needle sewing machine is equipped with a specialized needle that features two needle points on a single shank. This unique design enables the sewing machine to create two parallel rows of stitching simultaneously, which can add both functional and aesthetic value to sewing projects. The double needle is commonly used for hems, decorative stitching, and other applications where two lines of stitching are beneficial.

In the world of sewing, the zig zag stitch machine stands out as a remarkable and versatile tool that has revolutionized the way both professionals and hobbyists approach their craft. Since its inception, the zig zag stitch machine has expanded the creative possibilities for fabric manipulation, enabling seamstresses to create intricate designs, reinforce seams, and finish edges with ease.

In addition to enhancing creativity and precision, automatic computerized sewing machines also prioritize user comfort and efficiency. Many models are designed with ergonomic features, such as adjustable speed settings and easy-to-use interfaces that cater to users of all skill levels. The reduction of manual adjustments means that more time can be spent focusing on the artistic aspects of sewing rather than wrestling with complicated mechanics. This focus on user experience has made sewing more accessible to beginners, empowering a new generation of crafters.

Let’s look at the features:

2. Robust Construction The build quality of the machine is essential. A heavy-duty sewing machine typically has a metal frame that ensures stability during sewing, reducing vibrations and preventing skipping stitches.

Choosing the Right Twin Needle

When it comes to reliability and durability, a heavy-duty post bed sewing machine is a top choice for professionals in the sewing industry. Its heavy-duty construction and high-performance capabilities ensure that it can stand up to the rigors of daily use and deliver consistent results time and time again. Whether you are a seasoned seamstress or a novice hobbyist, a heavy-duty post bed sewing machine is a valuable investment that will help you take your sewing projects to the next level.

One of the standout qualities of an easy-to-use heavy-duty sewing machine is its straightforward setup process. Many models come with a clear instructional manual, guiding users through the initial setup, threading the machine, and making necessary adjustments. Some machines even feature automatic needle threading systems, which eliminate the hassle of manually threading the needle—a time-consuming step that can frustrate even seasoned sewers.

Moreover, fitting is an integral part of cutting line sewing. Once the initial assembly is completed, a fitting session is conducted to evaluate how the garment fits the wearer. Adjustments may be necessary to the cutting lines, allowing tailors to refine the fit further. This iterative process of cutting, sewing, fitting, and altering is what elevates a garment from a simple piece of fabric to a cohesive, well-fitting work of art.