1. Heavy-Duty Construction Upholstery fabrics are often thick and robust, such as canvas, denim, or leather. Seeking a sewing machine made with durable materials will ensure it can handle the stress of heavy fabrics without breaking or malfunctioning.

What is a Walking Foot Sewing Machine?

Understanding Cylinder Bed Sewing Machines

The Needle Feed Sewing Machine Revolutionizing Textile Production

2. High Stitching Speed Speed is of the essence in large-scale manufacturing. Machines that can operate at high speeds without compromising stitch quality enable manufacturers to meet demanding production schedules.

- 2. Fabric Choose a fabric suited to your project. Cotton is an ideal starting material due to its versatility and ease of handling.

- Proper care and maintenance of your lifting belt are also important to ensure its longevity and effectiveness. Be sure to clean your belt regularly and inspect it for any signs of wear or damage. If your belt becomes worn or frayed, it's time to replace it with a new one to ensure your safety and performance.

- - Quality A specialized machine helps produce clean and consistent stitches, elevating the overall quality of your craftsmanship.

A walking foot sewing machine is equipped with a special presser foot that has feed dogs on both the top and bottom. This dual feeding mechanism ensures that multiple layers of fabric or leather are moved through the machine evenly. Unlike traditional sewing machines, which rely solely on the bottom feed dogs, the walking foot allows for better control over thick materials such as leather, canvas, or upholstery fabric. This is particularly important when sewing bulky seams or handling slippery materials that can easily shift during the sewing process.

- Another popular option is the Brother ST371HD Strong and Tough Sewing Machine. This machine is known for its heavy-duty construction and ability to sew through multiple layers of fabric with ease. It features 37 built-in stitches, a metal needle plate for smooth fabric feeding, and a drop feed for free-motion sewing.

Selecting the Right Strong Needle

Applications in Sewing and Crafting

Arm sewing can be used to create a wide range of projects, from simple repairs and alterations to more complex garments and accessories. Whether you are a beginner or an experienced sewer, arm sewing offers a fun and rewarding way to express your creativity and enhance your sewing skills.

Overall, the 2% needle industrial sewing machine is a valuable tool for businesses in the textile industry. Its speed, precision, and versatility make it a reliable choice for a wide range of sewing tasks. Whether you are sewing garments, upholstery, or accessories, this machine can help you achieve professional results in a fraction of the time it would take with a traditional sewing machine.

A. Considerations Before Purchasing:

Here, we’ll provide a checklist of factors to consider when selecting a heavy duty sewing machine. This may include budget, intended use, available features, and the user’s skill level. By considering these aspects, readers can make an informed decision.

Heavy-duty machines often provide a range of needle choices. For light fabrics, slender needles like sizes 60/8 or 70/10 are appropriate, causing minimal puncture damage. Thicker fabrics, however, require heftier needles that can pierce through without bending or breaking. Moreover, specialized needles, such as ballpoint for knits or sharps for silks, further optimize the sewing process, tailoring the needle’s design to the fabric’s unique characteristics.

Finally, investing in a heavy duty sewing machine can be economically advantageous for businesses and serious hobbyists alike. The durability of these machines often translates into a longer lifespan, reducing the need for frequent repairs or replacements.

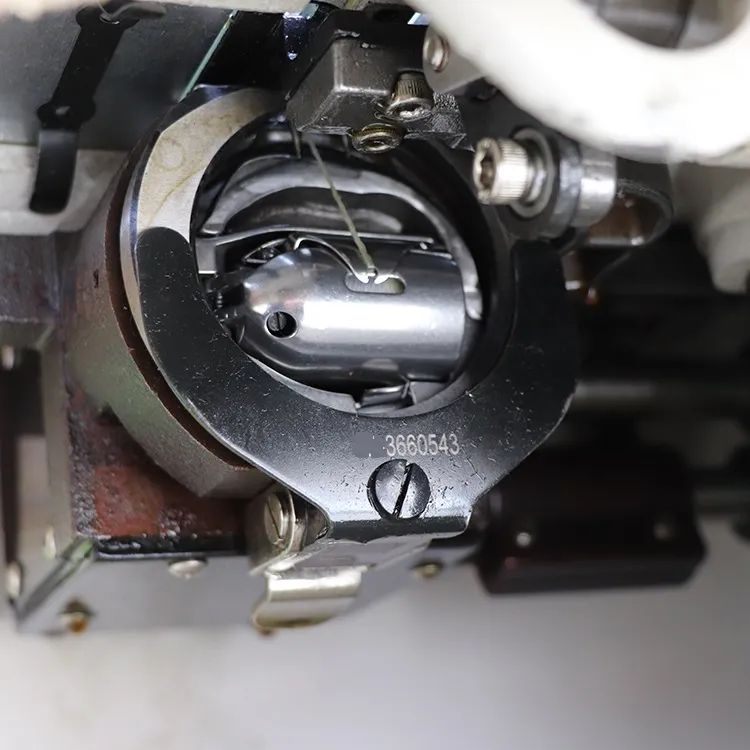

To fully leverage the capabilities of a double needle lockstitch machine, proper maintenance is essential. Regularly checking and replacing needles, maintaining the tension of the threads, and keeping the machine clean from lint and debris will help ensure consistent performance. Additionally, operators should be trained to adjust stitch density and tension settings according to the specific fabric being used, which can further enhance sewing quality.

Why Make Your Own Car Mats?

Professional upholstery machines not only improve the quality of stitching but also significantly increase productivity. The ability to sew through thick materials quickly translates to shorter project turnaround times. For businesses that rely on fast production rates, investing in a professional machine can lead to better profit margins.

heavy duty leather sewing machine. These machines are typically equipped with a range of stitch options, including straight stitches, zigzag stitches, and decorative stitches, allowing you to create a variety of finished looks on your leather projects. Some machines even offer programmable stitch settings, giving you even more control over the final outcome of your sewing.

Exploring Handheld Sewing Machines

The lockstitch sewing machine was first developed in the 19th century, with Isaac Merritt Singer often credited for popularizing it through his innovative designs. This machine revolutionized the textile industry, making it possible to sew pieces of fabric together faster and more precisely than ever before. The lockstitch mechanism, which interlocks threads from the needle and the bobbin, produces a strong and durable stitch that holds well under stress, making it ideal for various sewing projects.

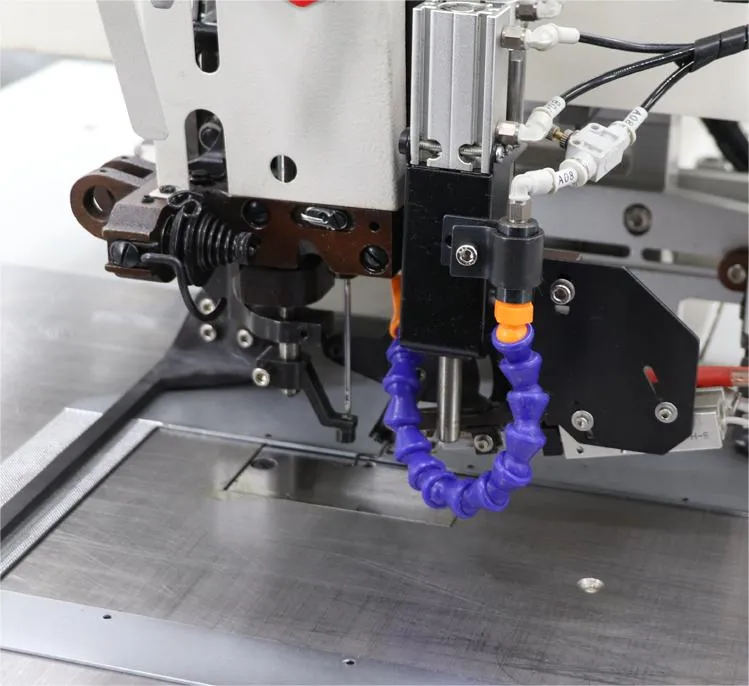

Heavy-duty sewing machines are designed to handle thicker fabrics and layers that standard machines may struggle with. They are built with robust construction and powerful motors, enabling them to stitch through multiple layers of materials such as denim, canvas, and upholstery fabrics. These machines often come equipped with upgraded features, such as heavier-duty needles, more robust feed systems, and metal frames, which contribute to their durability and efficiency.