One of the defining features of heavy-duty sewing machines is their robust construction. Unlike standard sewing machines, which may falter under the strain of thick fabrics, heavy-duty machines are built with stronger frames and powerful motors. This allows them to easily sew through multiple layers of fabric, leather, denim, and heavy canvas. Such resilience is particularly beneficial for those who work with tough materials on a regular basis. For instance, upholstery professionals often rely on these machines to create stylish yet hardy furniture covers, while outdoor enthusiasts may use them to make camping gear designed to withstand the elements.

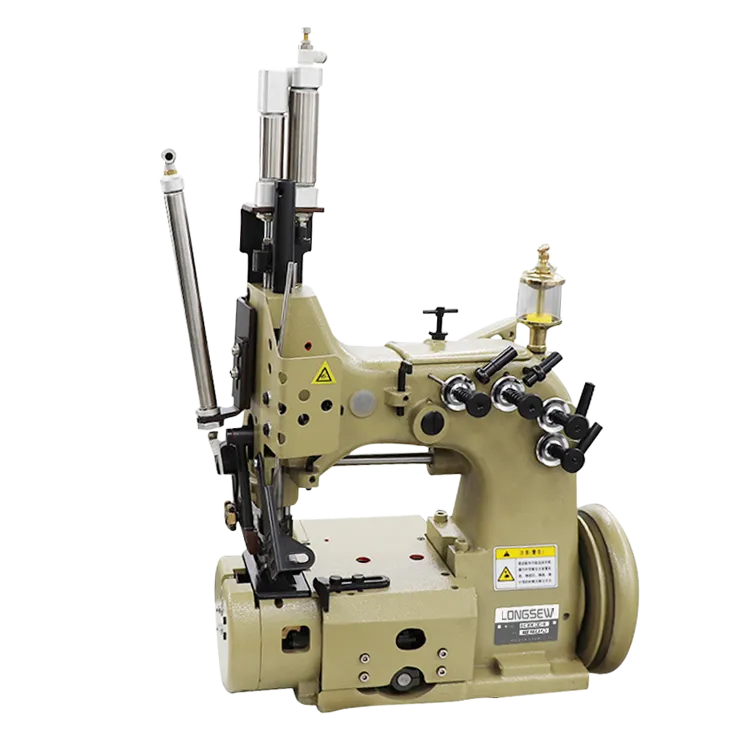

The concept of a sewing machine chain originates from the need for efficiency and speed in garment production. Before the advent of sewing chains, seamstresses relied heavily on manual sewing techniques, which were time-consuming and labor-intensive. The invention of the sewing machine introduced mechanized stitching, but it was the development of the sewing chain that took this innovation a step further. Sewing machine chains allow for continuous stitching across multiple layers of fabric, providing enhanced productivity and precision.

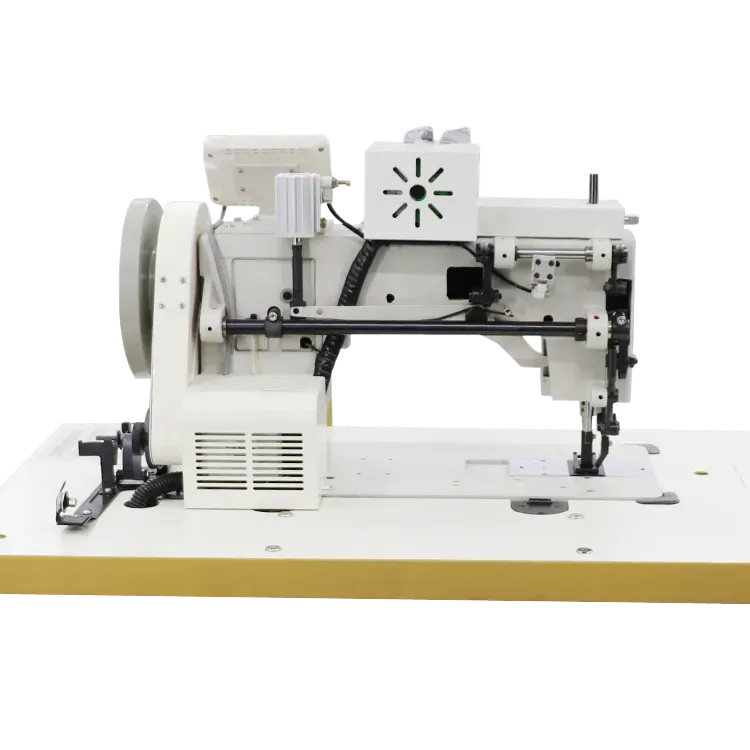

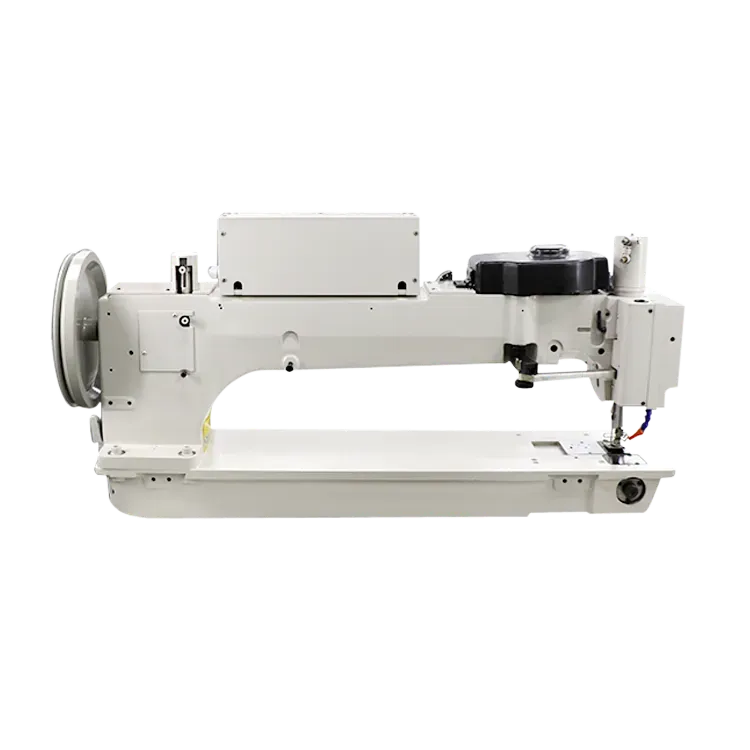

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

Evolution of CNC Machine Sewing

1. Choose the Right Needle It is essential to select the appropriate needle for sewing leather. Leather needles are specifically designed with a wedge-shaped tip to penetrate the material without causing damage.

When choosing the right heavy duty sewing machine for your needs, it’s important to consider several factors to ensure that you are making the best choice for your specific sewing projects. Firstly, assess your sewing needs and the types of materials you will be working with. If you primarily sew heavy fabrics such as denim, canvas, or leather, look for a heavy duty sewing machine that is specifically designed to handle these materials.

Arm sewing machines are also great for quick repairs or small sewing tasks, as they can easily be set up and put away when not in use Arm sewing machines are also great for quick repairs or small sewing tasks, as they can easily be set up and put away when not in use

Arm sewing machines are also great for quick repairs or small sewing tasks, as they can easily be set up and put away when not in use Arm sewing machines are also great for quick repairs or small sewing tasks, as they can easily be set up and put away when not in use