1. Efficiency One of the primary benefits of a handheld leather stitcher is its ability to significantly reduce the time required to sew pieces together. The tool's design allows for streamlined motion, enabling crafters to make quick and consistent stitches. This efficiency is especially beneficial for larger projects where traditional methods might become cumbersome.

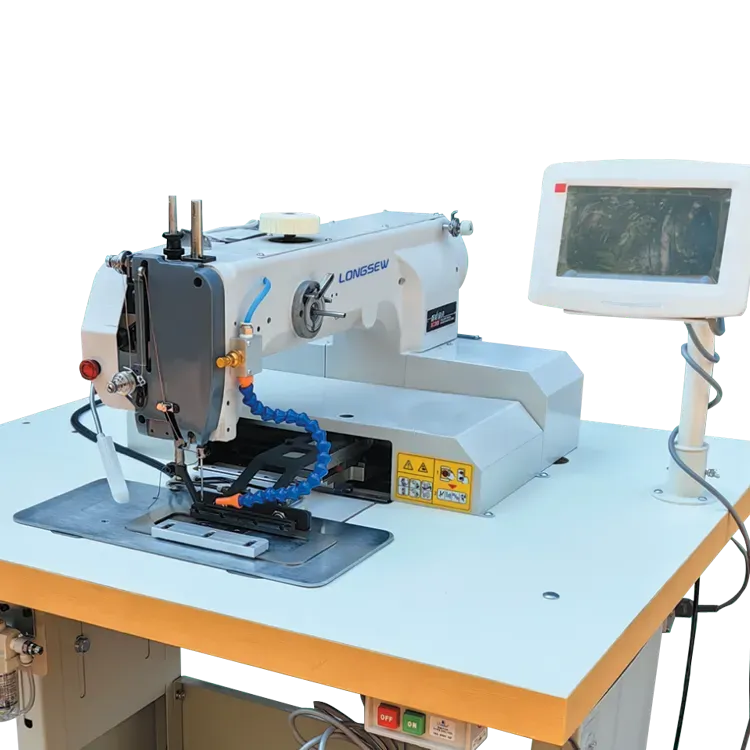

In summary, the lockstitch sewing machine is a cornerstone of the textile industry, combining strength, versatility, and precision to meet the demands of modern manufacturing. As fashion trends evolve and production techniques become more sophisticated, the role of the lockstitch machine remains significant. Its ability to produce durable and high-quality seams makes it essential not only for large-scale garment production but also for small businesses and home sewists alike. As the industry continues to innovate, the lockstitch sewing machine will undoubtedly adapt, maintaining its importance in the art of sewing and textile creation.

Advantages of Industrial Sewing Machines for Home Use

Investing in a heavy-duty sewing machine for canvas is a decision that can greatly enhance your sewing experience. These machines provide the power, durability, and precision needed to tackle various heavy fabric projects confidently. Whether you're a professional seeking reliability in your work or a hobbyist looking to expand your skill set, a heavy-duty sewing machine designed for canvas will undoubtedly be a valuable addition to your sewing toolkit. So, if you have a passion for creating with heavy materials, consider exploring the fantastic world of heavy-duty sewing machines and the endless possibilities they offer.

BENEFITS OF BUYING A HEAVY DUTY SEWING MACHINE

On the other hand, heavy-duty machines may have a steeper learning curve due to their advanced features and capabilities. However, this shouldn't deter beginners. Many heavy-duty models, offer helpful tutorials and guides to assist newcomers in mastering their machine's functions.

Applications in the Textile Industry

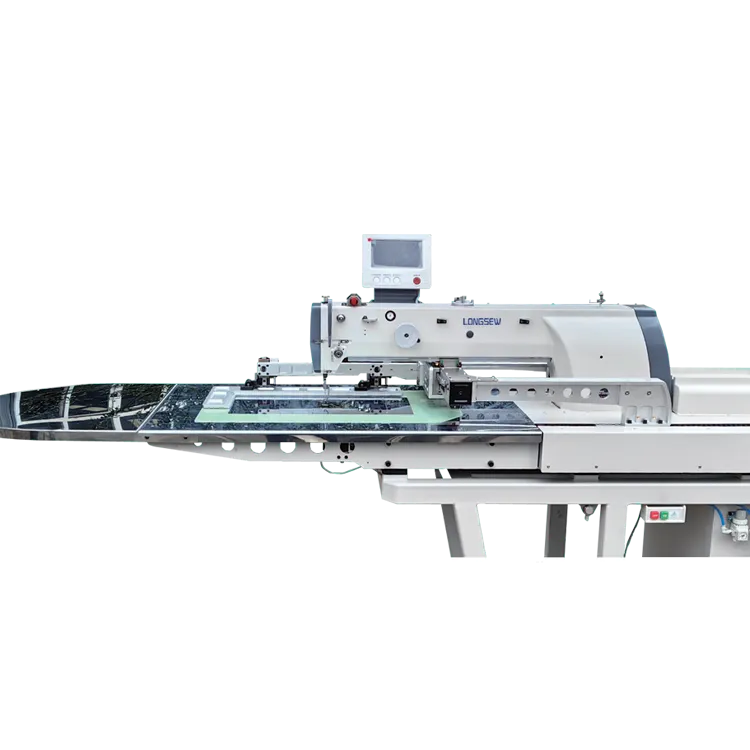

Moreover, automatic sewing machines contribute to cost efficiency. By minimizing labor costs and reducing fabric wastage through precision cutting and stitching, manufacturers can significantly lower their production expenses. This cost-effectiveness can translate into competitive pricing for consumers, making high-quality shirts more accessible. Furthermore, efficient production can lead to shorter lead times, allowing brands to introduce new collections and styles to the market promptly.

automatic sewing machine for shirts

Heavy-duty sewing is not just for professional seamstresses or tailors; it's an essential skill for anyone looking to create durable items or repairs on rugged fabrics. Everyday applications include making outdoor gear, upholstery for furniture, custom bags, and various craft projects. The durability of the seams and the quality of materials used play a significant role in ensuring the longevity of the finished product.

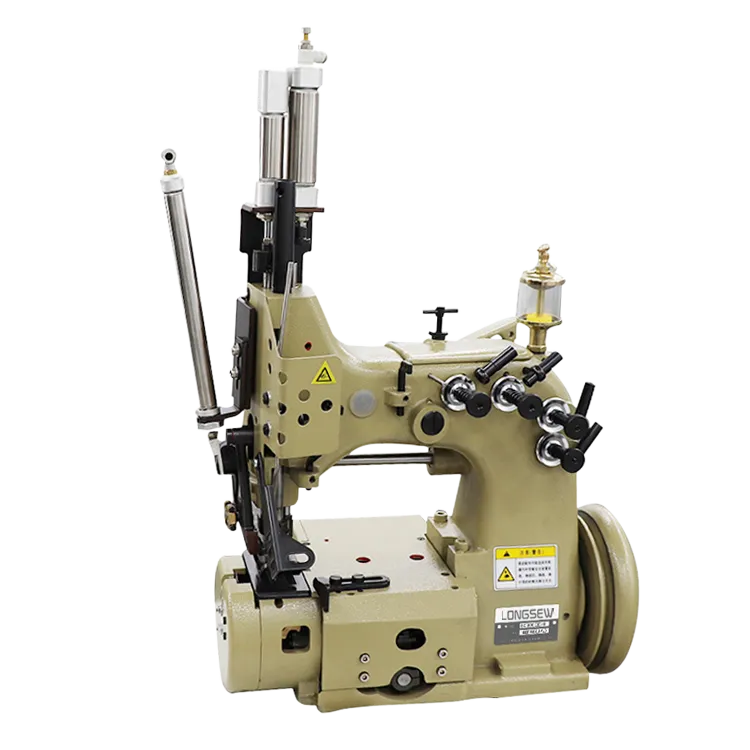

The continuous innovation within this segment ensures that these machines not only meet current industry standards but also anticipate future demands. In summation, a bag closing sewing machine is an indispensable tool in modern packaging, combining speed, precision, and adaptability to meet the diverse needs of various industries, thereby playing a critical role in maintaining the quality and safety of packaged goods.

Additionally, needle feed machines reduce the risk of fabric puckering, a common problem encountered when sewing delicate or stretchy materials. This capability is vital for maintaining the integrity of the fabric and achieving a professional finish, particularly in the fashion industry where aesthetics are paramount.

At the heart of the modern sewing machine lies the chain stitch mechanism. This technology uses a series of interlocking loops created by a needle and a looper. The chain stitch is distinctive due to its ability to create a durable seam that is both flexible and elastic. Unlike traditional lockstitches, which require two threads to form a cohesive seam, chain stitches use only one thread in a loop, significantly reducing the amount of material needed. This not only lowers costs but also accelerates the sewing process, enabling manufacturers to produce garments at a remarkable speed.

sewing machine chain

In the world of sewing and crafting, having the right tools can make all the difference. Amongst the myriad of equipment available, handheld leather sewing machines have carved a niche for themselves. These compact, portable devices offer numerous advantages, making them an invaluable asset for both amateur crafters and professional artisans.

The Growing Popularity of Serger Machine Sales

Extra heavy duty sewing machines have demonstrated exceptional performance and irreplaceable value across various fields as advanced mechanical equipment. Designed specifically for handling heavy materials, these sewing machines excel in the following areas with their powerful penetration and stable stitching: