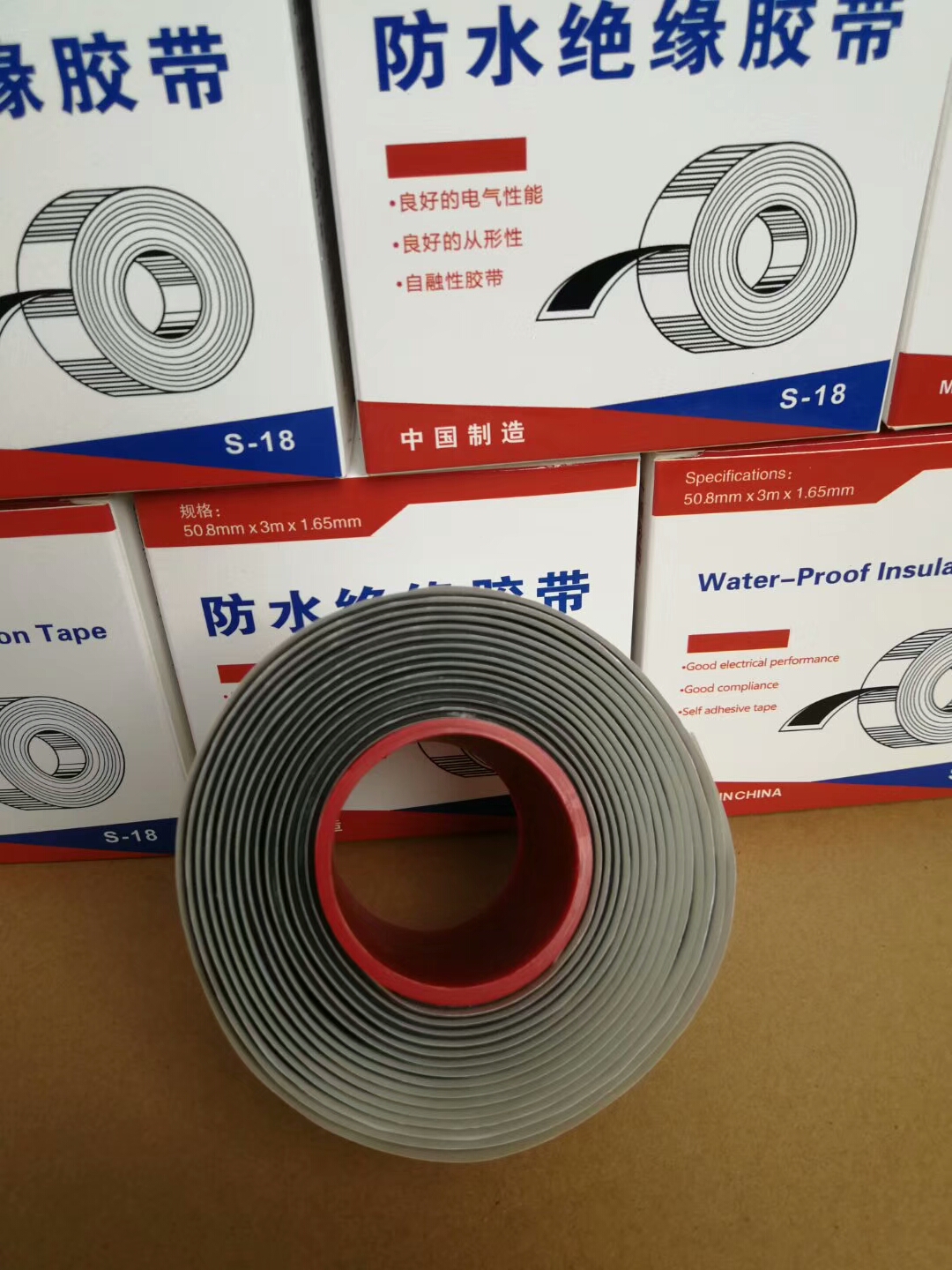

Just from looking at the roll, it is very hard to tell what type of rubber is used on the tape. Look at the figure to the right, and this same picture can be used to describe every type of rubber-tape below. The key is to ask the supplier what type of rubber adhesive is used. Like acrylics, rubber adhesives can be divided into two subgroups: Natural and Synthetic

Just from looking at the roll, it is very hard to tell what type of rubber is used on the tape. Look at the figure to the right, and this same picture can be used to describe every type of rubber-tape below. The key is to ask the supplier what type of rubber adhesive is used. Like acrylics, rubber adhesives can be divided into two subgroups: Natural and Synthetic

When was silicone tape invented?

Follow up this first step by wrapping four half-lapped layers of rubber insulating tape over the cambric tape, which creates a moisture barrier and provides the primary insulation in the connection. Finally, over-wrap the assembly with a minimum of two half-lapped layers of vinyl electrical tape. This should extend approximately two tape widths beyond the ends of the rubber tape. Stretch this tape as you wrap it so you get good conformance to the underlying structure. This also helps complete the moisture seal.

rubber tape for leaks. It can be used to patch up small holes in hoses, seal around windows and doors to prevent drafts, and even serve as a temporary fix for leaky roofs. Its weatherproof nature means it can withstand various climate conditions, making it suitable for indoor and outdoor applications.

rubber tape for leaks. It can be used to patch up small holes in hoses, seal around windows and doors to prevent drafts, and even serve as a temporary fix for leaky roofs. Its weatherproof nature means it can withstand various climate conditions, making it suitable for indoor and outdoor applications.Taping tips

How to Apply Butyl Tape

Silicone self-adhesive tape, also known as silicone tape or self-fusing silicone tape, is a remarkable material that is made from high-quality silicone rubber. It boasts unique properties that set it apart from traditional tapes, such as electrical tape or duct tape. This silicone tape is self-fusing, which means that when it is stretched and wrapped around an object, it bonds to itself, creating a watertight and airtight seal without the need for adhesives or glues.

One of the key advantages of butyl rubber strip is its exceptional resistance to extreme temperatures, making it an ideal choice for sealing and insulation purposes in environments with high heat or cold. Its ability to maintain flexibility and elasticity in a wide temperature range ensures a secure and tight seal, protecting against leaks and moisture ingress.

When using electrical tape, it is important to choose the right size and thickness for the job.