- Drill Rods These are the connecting links between the surface rig and the drill bit, allowing for the transmission of energy and air.

For details on shaft and housing design, please see the following:

Examples of allowable total eccentricity for oil seals

e3 diamond fire spark plugs. Their robust construction, featuring premium materials like platinum and iridium, ensures resistance against wear and tear, even under the most demanding driving conditions. The use of these precious metals also contributes to a longer service interval, reducing the need for frequent replacements.

e3 diamond fire spark plugs. Their robust construction, featuring premium materials like platinum and iridium, ensures resistance against wear and tear, even under the most demanding driving conditions. The use of these precious metals also contributes to a longer service interval, reducing the need for frequent replacements.(peripheral speed)

Shaft Stop Installation

14.2 Oil-Seal Requirements

Pressure - Many oil seals can only withstand low-pressure applications, so understanding the compression set of your components is key.

Oil seals are used for essential applications in the oil, gas and petrochemical sectors. They are created to avoid leaks from the sealing lip and rotary shaft by forming a thin layer of oil between them. Oil seals could be developed using well-known sealing materials, involving NBR, EPDM, PolyTetraFluoroEthylene (PTFE), Silicone,and fluoroelastomer.

Description

Heavy Duty Wheel Seals and Agricultural Equipment Seals can be divided into AP type, CRS type and ST type. Mainly be used in heavy pollution of agricultural machinery, construction machinery, mining equipment and trucks, buses and other environments. Compared to TC type, with special internal lubrication design, making it closed to the rotary shaft seal and bearing assembly which prevent external dirt effectively; a specially designed multi-lip inside the seal, makes it to achieve the function. Multiple external sealing lip design effectively prevents outside dirt and grease leakage immersion; the internal high-quality grease (butter) prevents muddy and water immersion.

Table 3: Features of each seal type

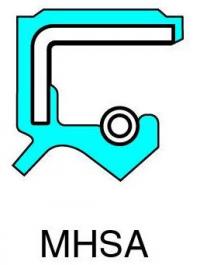

Seals are classified by O.D. wall material, lip type, and whether they have a spring or not.

Major oil seals are specified in ISO 6194-1 and JIS B 2402-1.

Table 2 shows the common types of oil seals, while Table 3 shows the features of each type of oil seal.

Table 4 lists the JTEKT oil seal type codes and corresponding ISO and JIS standards.