torre trasera del compresor de aire diesel

Drilling equipment is essential in various sectors, including oil and gas, mining, construction, and environmental research. Each sector requires specialized machinery capable of performing specific tasks effectively. For instance, in the oil and gas industry, rotary drill rigs and downhole drilling tools are critical for accessing subterranean resources. In contrast, the mining sector demands heavy-duty equipment designed to penetrate solid rock and extract valuable minerals.

As a merit in the mining of rock, the drilling rig has to be mentioned. In addition, the drilling rig can also be used as a breaker to break up hard layers such as concrete. According to its power source, the rock drill can be divided into four categories: pneumatic rock drill, internal combustion rock drill, electric rock drill and digging and changing drill.

Les matériaux utilisés dans les barres de forage

The following matters should be paid attention to during the use of the drilling rig, and the correct use can bring greater benefits

The following matters should be paid attention to during the use of the drilling rig, and the correct use can bring greater benefits

- Polycrystalline Diamond Compact (PDC) Bits Known for their durability and efficiency, PDC bits are suitable for softer formations and are often used in mineral extraction.

Conclusion

4. DIY Projects Hobbyists and DIY enthusiasts are also discovering the benefits of portable rotary air compressors, using them for various projects from woodworking to automotive detailing, proving that these machines are not just for professionals.

1. Offshore Oil and Gas Exploration In the oil and gas industry, submarine hammer drilling is crucial for the installation of subsea pipelines and wellheads. The ability to efficiently penetrate the seabed allows for the secure placement of infrastructure that can transport hydrocarbons from extraction points to processing facilities.

Manufacturers of self-priming slurry pump solutions offer customized solutions tailored to the specific needs of industries. Whether it's high-flow applications, corrosive environments, or heavy-duty operations, these pumps can be customized to meet the unique requirements of each industry.

Manufacturers of self-priming slurry pump solutions offer customized solutions tailored to the specific needs of industries. Whether it's high-flow applications, corrosive environments, or heavy-duty operations, these pumps can be customized to meet the unique requirements of each industry.

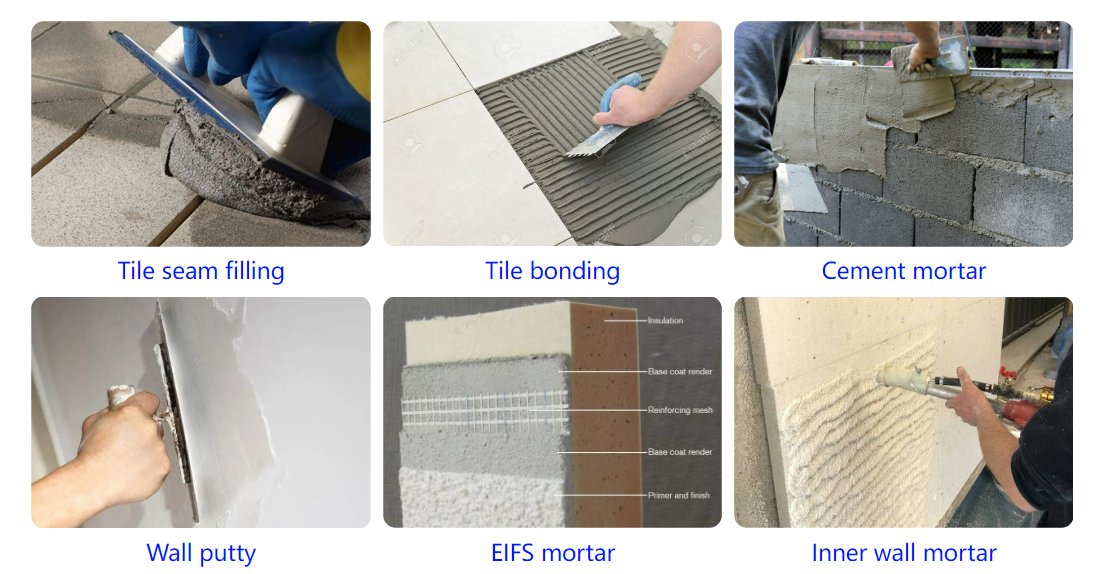

Its water retention properties prevent premature drying, improving workability and durability Its water retention properties prevent premature drying, improving workability and durability

Its water retention properties prevent premature drying, improving workability and durability Its water retention properties prevent premature drying, improving workability and durability