slurry pump working principle

5. Agriculture In agricultural settings, bullet teeth are utilized for soil preparation, allowing farmers to create optimal planting conditions.

The Price of Drilling Machines Factors Influencing Cost and Value

In summary, choosing the right pump for slurry applications is crucial to ensure efficient operation and minimize operational costs. Centrifugal and positive displacement pumps each have their distinct advantages, depending on the specific needs of the slurry being handled. By considering the properties of the slurry, pump material, required flow rates, operating conditions, and maintenance needs, industries can optimize their slurry handling processes for better performance and longevity. Ultimately, the right pump selection can lead to increased productivity and reduced wear and tear in industrial operations.

After 100 hours of operation, replace the engine oil, gear oil, motor oil, and brake fluid.

- Tricone Bits Comprised of three rotating cones, these bits are effective in various formations, especially in oil and gas drilling.

1. การก่อสร้าง ในสถานที่ก่อสร้าง คอมเพรสเซอร์ CFM 185 สามารถจ่ายลมให้กับเครื่องมือที่ใช้ในการขนย้ายวัสดุ หรือการตัดและเจาะที่มีความต้องการใช้งานที่ต่อเนื่อง ซึ่งช่วยเพิ่มประสิทธิภาพการทำงานและลดเวลาที่สูญเสียไป

compresseur d'air cfm 185

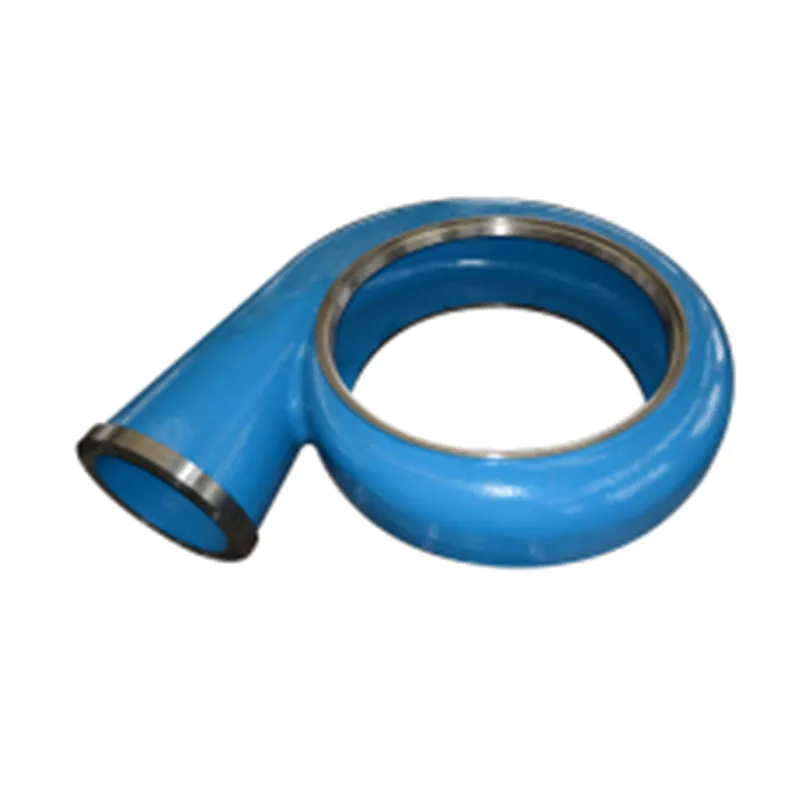

Innovations in Rubber Slurry Pump Technology

Submarine hammer drilling sees extensive applications in several sectors

Increased efficiency and productivity

- Reduced downtime and maintenance costs

- Enhanced performance in challenging environments

Increased efficiency and productivity

- Reduced downtime and maintenance costs

- Enhanced performance in challenging environments