Портативный screw air compressor

Chocks en los Laminadores Elementos Clave en la Industria Metalúrgica

Looking ahead, the future of drilling machines in mining appears promising. As technology continues to evolve, we can expect even greater improvements in efficiency, safety, and sustainability. Innovations such as artificial intelligence and machine learning could further refine drilling processes, enabling predictive maintenance and optimizing drilling parameters in real-time.

In the ever-evolving landscape of architecture and construction, the significance of roof covering cannot be overstated. Whether it's a residential abode, a commercial edifice, or a sprawling industrial facility, the roof serves as the first line of defense against the elements. It not only protects the structure but also enhances its aesthetic appeal. This is where the expert craftsmanship of a roof covering manufacturer comes into play.

Submarine hammer drilling sees extensive applications in several sectors

Another important factor contributing to the rising sales of drilling equipment is the growing emphasis on sustainable practices. As environmental concerns become more pronounced, companies are seeking ways to minimize their ecological footprints while meeting production demands. This demand has led to the development of eco-friendly drilling technologies, such as water-driven rigs and electric-powered drillers that reduce emissions and environmental disruption.

At its core, submarine hammer drilling employs a powerful hammer mechanism to drive a drill bit into the seabed. The system utilizes both air and water pressure to deliver repeated impacts on the drill bit, which enables it to break through hard rock formations or sediments that might hinder installation efforts for marine infrastructure. The design of the hammer ensures that the energy is efficiently transmitted to the drill bit, allowing it to operate at significant depths.

Spiral drill bit teeth represent a significant advancement in drilling technology. Their unique design and multiple benefits make them a preferred choice in many applications. By understanding the features and advantages of spiral drill bit teeth, professionals can select the right tools to enhance their drilling operations and achieve optimal results. Whether in construction, automotive, woodworking, or manufacturing, spiral drill bits are instrumental in driving productivity and precision in today's demanding working environments.

Additionally, cast iron panels provide security without compromising on style. Fencing and gates made from ornamental cast iron can deter unauthorized access while still looking elegant and inviting. This balance between security and aesthetics appeals to many property owners seeking to enhance their home’s curb appeal while ensuring safety.

Thus, aluminum profiles for windows and doors with anodized finish are resistant to corrosion since the layer prevents it from occurring.

Durability and Strength

Modern steel security safe lock boxes are equipped with advanced security features that provide an added layer of protection. Many models come with electronic lock systems that allow for personalized access codes, eliminating the need for traditional keys that can be lost or duplicated. Some safes even incorporate biometric scanners that use fingerprint recognition, ensuring that only authorized individuals can gain access. These high-tech features significantly reduce the risk of unauthorized entry, giving users peace of mind.

Wrought iron is widely renowned as a material for building fences and gates due to its longevity and durability. If maintained properly, your wrought iron fences and gates could last upwards of a decade. Here, all of our wrought iron products are galvanised to prevent the formation of rust for up to ten years, but if properly maintained, your wrought iron fences and gates could easily last a lifetime.

The Benefits of Aluminum Window Frame Extrusions

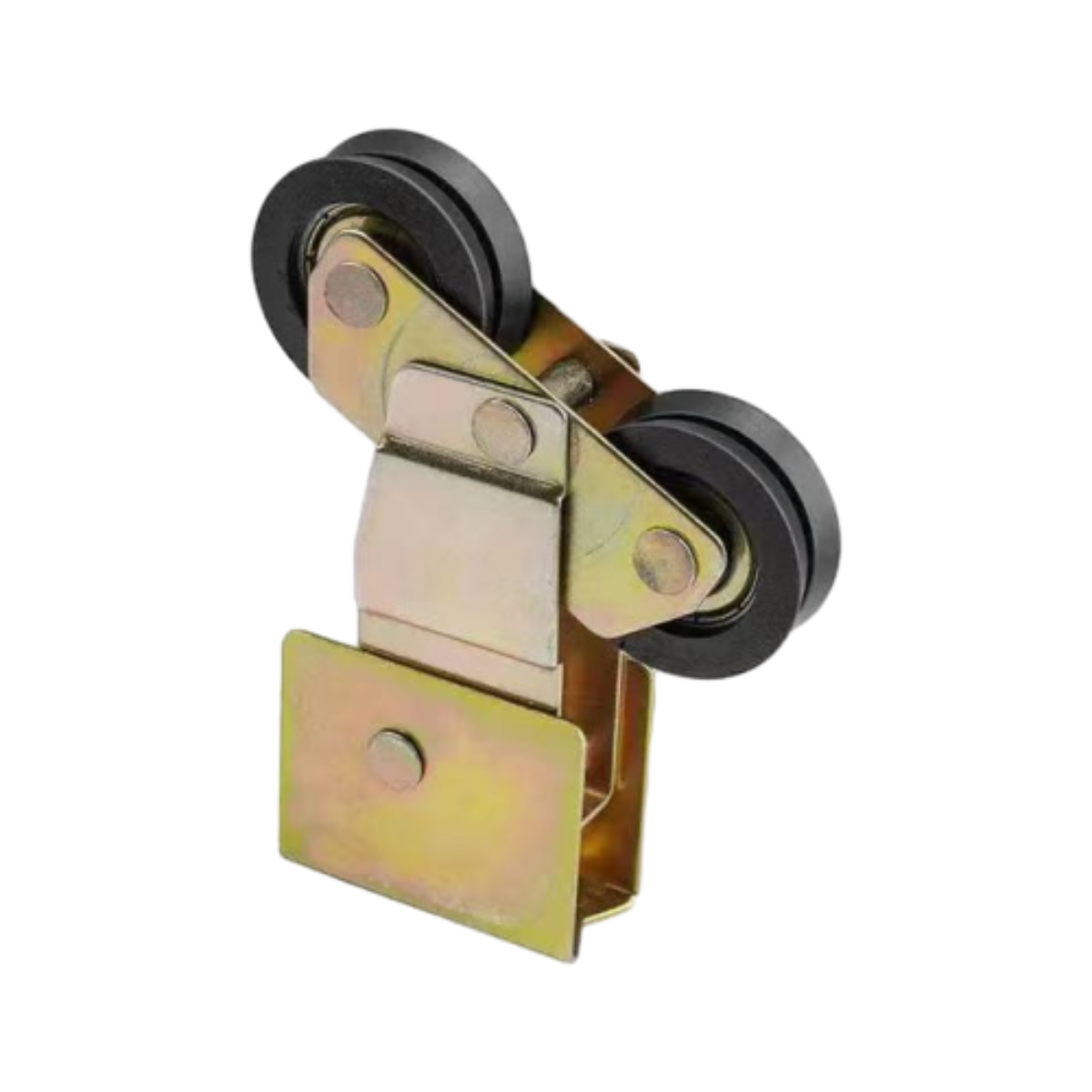

Plastic protective film+wooden strip+steel trolley

As we draw this conversation on aluminum vs wrought iron fence to a close and leave you to consider your fencing options, don’t forget that in Texas is your one-stop solution for premier wrought iron fences – and all things fence supply Austin, for that matter.

1. Posts

The most common component of contemporary wrought iron fences is the tubing made of iron or steel. The tubes are worked into forms by machines, and the manufacturers also utilize devices to produce the decoration traditionally used with a wrought iron fence. The lines are welded together to form wall panels, resulting in a robust iron fence.

we typically use one-inch square posts core drilled and set in hydraulic cement when we’re installing railings. For fencing, we use heavy duty steel posts that we galvanize, prime, and paint, set into concrete footings. The environment of your property may influence preparations as well: for instance, galvanizing is particularly important if the structure is near water.

In addition to their durability, cast iron fence panels are also known for their aesthetic appeal. The intricate designs and patterns that can be molded into cast iron make these panels a beautiful addition to any property. Whether you prefer a classic design with ornate scrolls and finials or a more modern look with clean lines and geometric shapes, there are cast iron fence panels available to suit any taste.

Minimalist designs often feature clean lines and geometric shapes, exuding a contemporary and sophisticated vibe Minimalist designs often feature clean lines and geometric shapes, exuding a contemporary and sophisticated vibe

Minimalist designs often feature clean lines and geometric shapes, exuding a contemporary and sophisticated vibe Minimalist designs often feature clean lines and geometric shapes, exuding a contemporary and sophisticated vibe main gate steel gate handle design. On the other hand, ornate designs, adorned with intricate patterns or motifs, bring a touch of traditional elegance and grandeur.

main gate steel gate handle design. On the other hand, ornate designs, adorned with intricate patterns or motifs, bring a touch of traditional elegance and grandeur.Due to the price of materials and the relative difficulty of installation, wrought iron fences are usually more expensive than aluminum fences—but not by much.