Rollers are essential for the operation of sliding windows. They facilitate the smooth sliding motion, allowing users to easily open and close the windows without excessive force or strain. A well-functioning roller system minimizes wear and tear on the window frames and tracks, extending the life of the windows themselves. Additionally, high-quality rollers contribute to better insulation, reducing energy loss and enhancing the overall efficiency of the home.

What Is Wrought Iron?

Aluminum profiles for windows and doors have varied quality standard specifications.

Benefits of Aluminum ornamental fence

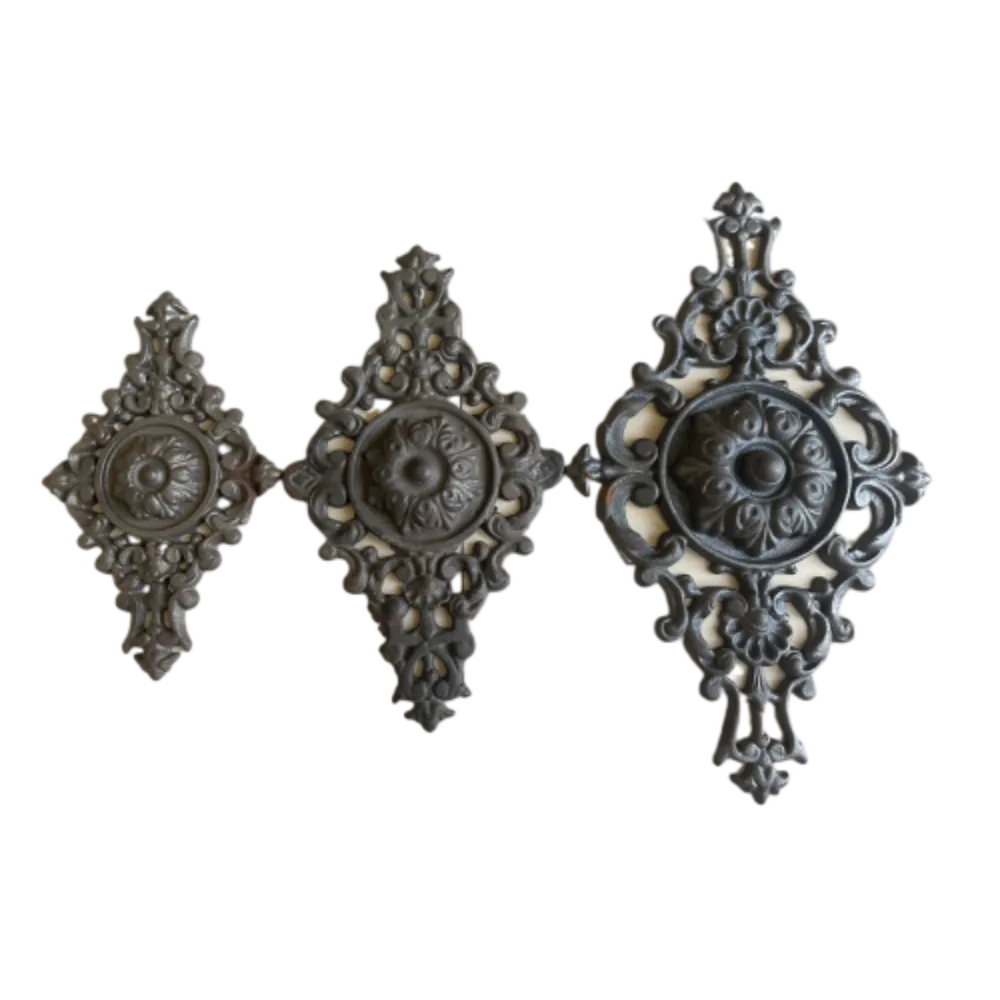

Cast Iron Railing Panel

Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters

Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters Moreover, their quiet operation adds to the ambiance, particularly in settings where tranquility is desired, such as libraries, bedrooms, or home theaters door sliding wheel.

door sliding wheel.Profilati Alluminio manufactures and ships worldwide – thus in the U.S. too – various types of aluminum extrusions also with extremely small dimensional tolerances: among them, aluminum window extrusion profiles.

Another benefit of aluminum window extrusion profiles is their sleek and modern look. The slim frames of aluminum windows allow for larger panes of glass, maximizing natural light and views from inside the home. Additionally, aluminum frames can be designed with clean lines and sharp angles, creating a contemporary and minimalist aesthetic that is popular in modern architecture.

aluminum window extrusion profiles

sliding window roller wheel. By providing a tight seal when closed, they help prevent air leakage, thereby maintaining indoor temperature and reducing energy consumption for heating or cooling. This not only benefits the environment but also translates into cost savings for homeowners.

sliding window roller wheel. By providing a tight seal when closed, they help prevent air leakage, thereby maintaining indoor temperature and reducing energy consumption for heating or cooling. This not only benefits the environment but also translates into cost savings for homeowners.In addition to their practical and aesthetic qualities, wrought iron railing panels also contribute to the sustainability narrative

. The material is recyclable, and well-maintained panels can last for generations, reducing the need for frequent replacements and minimizing waste.Finally, if you’re someone who loves to stamp your own personality onto your property, wrought iron gives you that creative freedom. This is especially true when you partner with us, as our wrought iron fences are totally custom.

Next, locate the roller assembly, which is typically situated at the top of the door. There may be one or two rollers, depending on the door design. Use your screwdriver to remove the screws securing the roller assembly to the door. Some doors may have a cover that needs to be taken off before accessing the rollers; gently pry it off with pliers if necessary.

changing screen door rollers

Brand

The material of an aluminium window profile is primarily aluminium. This metal provides a strong, lightweight, and durable framework for the window. Aluminium window profiles are often extruded, meaning they are formed by pushing aluminium through a die to create a long, seamless profile that can be cut to size.

Aluminum window profiles are made of aluminum alloys such as 6063, 6060, 6061, 6005, and 6082 12. These alloys are known for their corrosion resistance and strength-to-weight ratio. The aluminum billet used to make these profiles is typically of national standard .

To enhance the performance characteristics of the window profile, aluminium may be alloyed with other elements, such as copper or zinc, to increase its strength. Additionally, the surface of the aluminium can be coated with paint, anodized, or finished with a powder coating to improve its appearance, resistance to wear, and protection against the elements.

In some cases, other materials may be used in conjunction with the aluminium, such as polyamide or thermal breaks to improve insulation and reduce heat transfer. These materials are often integrated into the design of the window profile to create a more energy-efficient product.

Here are the steps to follow

Here are the steps to followBringing Our Conversation on Wrought Iron Fence vs Aluminum Fence to a Close

There are several tips for you in selecting a high-quality aluminium window. First and foremost, the thickness of aluminium profiles of the aluminium windows should not be less than 1.2mm. Tempered glass or laminated glass are also better than float glass. If you consider the safety and durability of the windows, choose stainless steel hardware accessories (such as screws, hinges, handles, etc.) It is also advisable to choose pulley that is made of POM material. These products have higher strength and abrasion resistance. They are smooth during operation and not easily damaged.

First and foremost, quality is paramount when it comes to wrought iron products. A reliable supplier should provide materials that meet industry standards for strength and durability. Low-quality wrought iron can lead to safety issues, especially in structural applications. Buyers should look for suppliers who can demonstrate compliance with relevant standards or certifications. Additionally, customers should ask about the supplier's production processes and whether they employ quality control measures to ensure that the finished products are free from defects.