fabricante de martillo.

4, the selection of rolling drag plate, the track is not easy to wear.

4, the selection of rolling drag plate, the track is not easy to wear.

Submarine Hammer Drilling An Insight into Techniques and Applications

4, the selection of rolling drag plate, the track is not easy to wear.

Moreover, the tableau has emerged as a powerful tool in activism and social commentary. Artists and activists have used staged tableaux to highlight social issues, drawing attention to injustices and sparking conversations around topics such as race, gender, and inequality. For example, in response to police brutality and systemic racism, performance artists have created striking tableaux that encapsulate the pain and resilience of marginalized communities. These artistic expressions not only evoke empathy but also challenge audiences to confront uncomfortable truths about society.

2. Versatility Fractional head hammers can often be adapted for various tasks, eliminating the need for multiple hammers. For instance, one section may be designed specifically for driving nails, while another could be used for shaping or forming materials. This versatility saves time, reduces the number of tools needed on-site, and allows for greater efficiency in workflow.

1. Construction On construction sites, these compressors are used for powering tools, inflating tires, and even dust control. Their portability allows workers to bring the air source directly to where it's needed, minimizing downtime.

5. Eccentric Shaft

Moreover, forage drilling techniques have evolved significantly with advancements in technology. Modern drilling rigs are more efficient and environmentally friendly, minimizing the ecological footprint of the drilling process. New methods such as rotary and air drilling have made it possible to access deeper aquifers, ensuring that even arid regions can find adequate water sources. Furthermore, innovations in drilling technology allow for real-time monitoring of groundwater levels and quality, ensuring that water extraction remains sustainable over time.

The main components of submarine hammer drilling equipment include the drill rig, hammer, drill pipes, and the drill bit. The drill rig is often mounted on a surface vessel or a floating platform and is designed to support the excessive weight and dynamic forces encountered during drilling operations.

Moreover, the environmental impact of material transportation is a growing concern in today's industrial landscape. Gravel pump manufacturers are increasingly investing in research and development to create more sustainable pumping solutions. This involves designing pumps that not only handle materials more efficiently but also reduce energy consumption and lower emissions. Such innovations are not only beneficial for the environment but also lead to cost savings for businesses in the long run.

Additionally, slurry pumps are used in tailings management, which refers to the disposal of waste materials left after the extraction of precious minerals. Efficiently transporting tailings to storage facilities ensures that mining operations remain sustainable and do not pose environmental hazards. The design and efficiency of a slurry pump can significantly impact the overall productivity of a mining operation, underlining their importance.

In conclusion, HPMC Company exemplifies what it means to be at the intersection of innovation and sustainability. By harnessing the unique properties of HPMC and committing to responsible practices, the company is shaping industries and ensuring that its products enhance everyday life while safeguarding the environment for future generations. As it continues to grow and adapt, HPMC Company remains dedicated to delivering excellence and driving progress in the fields it serves.

Un altro aspetto significativo della polvere ridispersibile è la sua facilità d'uso. Gli operatori del settore possono facilmente incorporarvi questa polvere nella loro formulazione, senza necessità di attrezzature complesse. Inoltre, il prodotto è disponibile in diverse formulazioni, consentendo agli utilizzatori di scegliere quella più adatta alle loro esigenze specifiche.

चिपकने वाले एडिटिव का मुख्य उद्देश्य सिमेंट की ताकत को बढ़ाना और उसके कार्यक्षमता को सुधारना होता है। ये एडिटिव विभिन्न प्रकार के होते हैं, जैसे कि पॉलिमर, एंटीफ्रीज एजेंट, आणविक संरचना को बेहतर बनाने वाले तत्व, और पानी की अवधारण क्षमता बढ़ाने वाले पदार्थ। इसके माध्यम से, सिमेंट की गुणवत्ता में सुधार होता है और यह वायुमंडलीय परिस्थितियों के प्रति अधिक सहिष्णु बनता है।

1. Cosmetics and Personal Care HEC is commonly used in skincare products, shampoos, conditioners, and lotions. Its thickening properties improve the texture of these products, while its film-forming ability provides a protective barrier on the skin and hair.

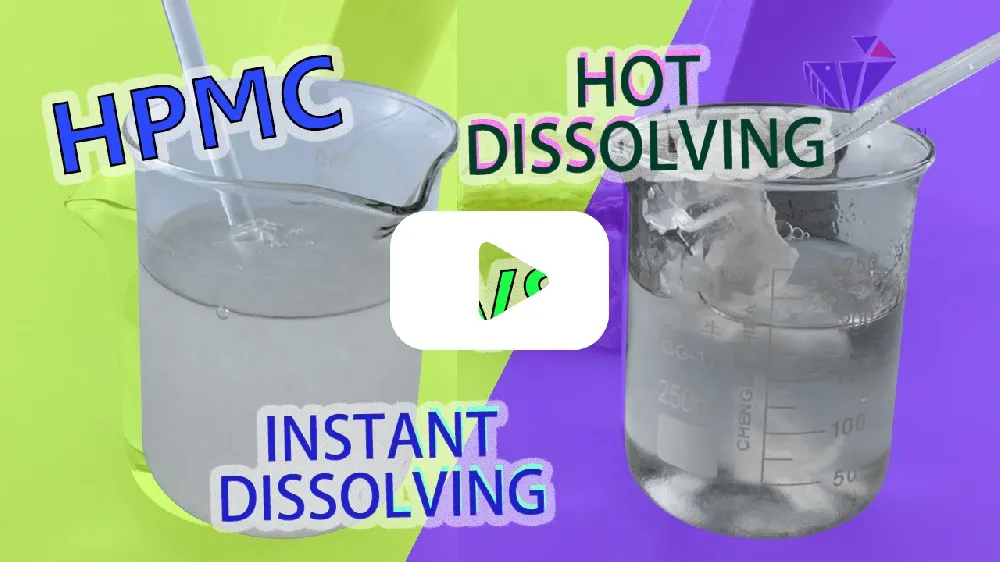

Properties of HPMC

The Uses of Hydroxypropyl Methylcellulose

En la construcción, la HEC se ha convertido en un aditivo esencial en morteros y adhesivos, donde mejora la trabajabilidad y la retención de agua. Los fabricantes en este campo están constantemente investigando y desarrollando nuevas variantes de hidroxietilcelulosa que se adapten a diferentes aplicaciones y condiciones ambientales, garantizando así un rendimiento óptimo.

Market Demand and Applications

Applications of HPMC Detergent

Redispersible polymer powder (RDP) has emerged as an essential ingredient in various industries, particularly in construction, coatings, and adhesives. These polymer powders are typically derived from emulsions and are designed to improve the performance characteristics of end products. As with any commodity, the price of redispersible polymer powder is influenced by a myriad of factors that vary across different markets and applications.

Beyond pharmaceuticals, PMC's unique properties make it a popular choice in the food industry. It is used as a thickening agent, emulsifier, and stabilizer in a wide range of food products, including sauces, dressings, dairy products, and baked goods. Its ability to retain moisture contributes to the texture and shelf-life of food items, making it an essential ingredient in processed foods. Additionally, as consumers increasingly seek gluten-free alternatives, PMC serves as an important substitute in gluten-free formulations due to its excellent binding and textural properties.

Beyond pharmaceuticals and cosmetics, HEC is extensively used in the construction industry. It serves as a vital component in cement and plaster formulations, where it enhances workability and prevents segregation. The viscosity control offered by HEC allows for easier application and improved adhesion of materials, which is critical for ensuring quality in construction projects.

HPMC Solutions LLC Un Partenaire Stratégique pour l'Innovation Technologique

4. Wuxi Dongtai Chemical Co., Ltd. This manufacturer focuses on catering to the construction industry, providing specialized HPMC products for tile adhesives, wall putty, and other mortars. Their products are known for enhancing workability and improving end-product performance.

Další zajímavostí je, že HPMC je veganský a bezlepkový produkt, což ho dělá atraktivním pro výrobce, kteří cílí na specifické segmenty trhu se zvláštními požadavky na složení výrobků

.HPMC is composed of hydroxypropyl and methyl substituents attached to the cellulose backbone, which is derived from natural sources like wood pulp or cotton. This chemical modification enhances the solubility of cellulose, making HPMC a water-soluble polymer. The chemical structure of HPMC varies depending on the ratio of hydroxypropyl and methyl groups, leading to different grades of HPMC, each designed for specific applications.

3. Construction HPMC is a critical additive in cement and plaster formulations. It improves the workability and adhesion of construction materials, leading to more robust and durable products. Additionally, HPMC helps control the drying time and consistency of mortars and tile adhesives, ensuring easier application and better performance.

4. Dryness and Irritation In topical formulations, HPMC may cause dryness or irritation for some individuals, particularly those with sensitive skin. It is advisable to conduct a patch test before using products containing HPMC to check for any adverse reactions.

In personal care products, HEC is commonly used as a thickening agent in creams, lotions, shampoos, and gels. Its ability to retain moisture and create a pleasant skin feel makes it an essential component in hydrating formulations. Moreover, its film-forming properties provide a protective barrier, enhancing the longevity of cosmetic products.

3. Additivi anti-ritiro Per prevenire il ritiro della malta durante il processo di asciugatura, è possibile utilizzare additivi specifici che riducono le tensioni interne, evitando così la formazione di crepe.

Once the quality checks are passed, the HEC is packaged in appropriate materials that protect it from moisture and contamination during storage and transport. It is essential for manufacturers to provide clear labeling and technical data about the product to inform users of its properties and applications. The final step involves the distribution of HEC to various markets, where it is utilized in formulations ranging from thickening agents in paints to stabilizers in food products.

Die Auswahl des richtigen Herstellers ist entscheidend, um die gewünschten Eigenschaften der Bauchemie zu erreichen. Anbieter, die hohe Qualitätsstandards einhalten und über umfassende Erfahrung in der Branche verfügen, können den Unterschied ausmachen, wenn es darum geht, die Leistung der Endprodukte zu maximieren.

7. Storage

The solubility of HPMC is critical in determining its effectiveness in various applications. For instance, in pharmaceuticals, HPMC is often used as a binder in tablet formulations, as a drug release modifier in controlled-release systems, and as a stabilizer in suspensions. The right grade of HPMC can significantly influence drug release rates and bioavailability. In food applications, HPMC serves as a thickening agent, emulsifier, and stabilizer, whereas in cosmetics, it acts as a film-forming agent and moisturizer. Therefore, understanding the solubility of HPMC is vital for optimizing formulations and ensuring product performance.

In the food industry, HPMC is used as a food additive and thickening agent. Its ability to retain moisture helps improve the texture and shelf life of a wide range of food products, including baked goods, dairy products, sauces, and dressings. HPMC can also function as a stabilizer and emulsifier, ensuring consistent quality in processed foods. Given the increasing demand for gluten-free and vegan products, HPMC serves as an effective substitute for gluten, providing desirable texture and structure to gluten-free alternatives.

3. Market Demand Demand from various end-use industries plays a critical role in shaping HEC prices. The pharmaceutical industry demands HEC for its applications in drug formulation and controlled release systems, while the cosmetic sector utilizes it for creating emulsions and gels. Increasing consumer demand for personal care products, along with ongoing innovations in drug delivery systems, often drives up prices as manufacturers strive to meet the heightened needs.

In the realm of cosmetics and personal care, HPMC is prized for its thickening and stabilizing properties. It is commonly found in lotions, creams, and gels, where it enhances texture and provides a smooth application. Furthermore, HPMC's ability to form films makes it an excellent choice for products such as hair gels and facial masks, delivering a pleasant sensory experience while ensuring that active ingredients remain effective.

2. Enhanced Workability HPMC enhances the workability of tile adhesives, making them easier to spread and manipulate during application. This characteristic allows contractors to achieve a smooth, even application, which is vital for ensuring that tiles are precisely aligned and firmly attached to the substrate.

Another noteworthy property of RPP is its impact on the mechanical strength and thermal stability of the end products. The presence of the polymer improves the toughness of brittle materials, making them more resilient to cracking and wear. This is particularly beneficial in environments that subject materials to stress and temperature fluctuations.

Dispersible polymer powders have emerged as a versatile category of materials with a wide range of applications, from construction to consumer goods. These powders are made from polymers that can easily disperse in water, forming a homogenous mixture that retains the beneficial properties of the original polymer. This article will delve into the composition, properties, and various applications of dispersible polymer powders.

HPMC Viskoznost Ključni Aspekti i Primjene

Inoltre, c'è una crescente attenzione verso la sostenibilità. Molti produttori stanno investendo nella creazione di agenti di legame ecologici, realizzati con materiali biodegradabili o riciclati, per ridurre l'impatto ambientale e promuovere un'economia circolare.

Understanding HPMC Viscosity Grades

3. Adhesives RDPs are also utilized in the formulation of adhesives, where they enhance bonding strength and flexibility. This is particularly important in applications where materials may experience movement or thermal expansion, such as in construction and automotive industries. The ability of RDPs to improve wet and dry adhesion makes them indispensable in producing high-performance adhesives.

HPMC Solution Preparation A Comprehensive Guide

HEC Cellulose Properties, Applications, and Benefits

E le fa'atekinolosi fa'amalieina lenei tulaga i se tulaga e lelei ai mo tagata o le atunaʻe atoa. E mafai ona fesoasoani i le fa'atuina o fa'avae ma fa'avae e le gata i le malosi ma le fa'avae o le ciment, ae e mafai fo'i ona fesoasoani e puipuia le siosiomaga e ala i le fa'aitiitia o le fa'aaogaina o le malosi e manaʻomia mo le fa'avae. O le 'adhesive additive' e avea ma se ala e fesoasoani e fa'ateleina le lelei ma le amana'ia o le fa'avaa i le taimi e le mana'omia ai.

V potravinářství je HPMC rovněž velmi užitečná. Používá se jako zahušťovadlo, stabilizátor a emulgátor. Pomáhá při výrobě různých potravinových výrobků, jako jsou omáčky, pudinky a zmrzliny, kde zajišťuje optimální konzistenci a stabilitu. Díky své nezávadnosti a hypoalergenním vlastnostem je HPMC vhodná pro použití v potravinách určených pro alergiky a osoby se speciálními dietními potřebami.

Co je hydroxypropylmethylcelulóza?

Another significant application of hydroxyethyl cellulose is in the construction industry, particularly in the formulation of cementitious materials and mortars

. When added to these mixtures, HEC enhances water retention, workability, and open time, allowing for better processing and application. The use of HEC in cement-based products can also improve adhesion and reduce cracking, contributing to the overall durability and performance of the materials.

HPMC Cellulose Isang Mahalagang Sangkap sa Ibang-ibang Industriya

Истеҳсолкунандагон ва фурӯшандагон иҷозат доранд, ки ба нарх ва сифати Гидроксиэтил целлюлоза диққат диҳанд, то эҳсос кунанд, ки кифоя аст ё на. Бо назардошти ин, бояд қайд шавад, ки бо ташкил кардани муомилаҳо ва ҳамкорӣ бо таъминкунандагони боэътимод, нархи Gidroxietilsellyuloza метавонад дар чаҳорчӯби нархҳои муқаррарӣ ва стандартӣ қарор гирад.

What is HPMC?

4. Cosmetics In cosmetic formulations, HPMC acts as a thickener and stabilizer in creams, lotions, and gels. Its film-forming properties contribute to the texture and feel of personal care products, enhancing consumer experience.

Incorporating HPMC into skim coat formulations offers numerous benefits, enhancing the performance, quality, and durability of wall finishes. As a water-retaining and thickening agent, HPMC not only improves workability but also ensures strong adhesion and reduces the occurrence of cracks. Given the ever-growing demands in the construction industry for high-quality finishes, HPMC will continue to play a pivotal role in the development of advanced skim coat products. As manufacturers strive to meet these demands, the importance of HPMC in skim coats becomes increasingly evident, underscoring its value in modern construction practices.

Por fim, a hidroximetilcelulose propílica é também aplicada em indústrias de construção e materiais. Ela é utilizada em argamassas, tintas e produtos de revestimento, onde sua função como espessante e agente de retenção de água melhora a trabalhabilidade e a durabilidade das misturas.

Production Process

Il metanolo, un solvente organico comune, è noto per la sua capacità di dissolvere una vasta gamma di sostanze chimiche. La solubilità dell'HPMC nel metanolo dipende da diversi fattori, tra cui la temperatura, il grado di sostituzione della cellulosa e la concentrazione del polimero. In generale, l'HPMC presenta una buona solubilità in solventi polari, e il metanolo, essendo un solvente polare, può effettivamente dissolvere questo polimero fino a concentrazioni elevate.