Furthermore, environmental factors and consumer preferences are prompting the development and use of new HPMC grades. With a growing emphasis on sustainability, many manufacturers are exploring bio-based alternatives and improving the eco-friendliness of HPMC products.

Methylcellulose has a lower molecular weight, which makes it more soluble and dispersible in water. As a result, it is often used as a thickening agent in food and personal care products, such as shampoos and lotions.

- HPMC, or hydroxypropyl methylcellulose, is a versatile and widely used material in various industries. It is commonly used as a thickening agent, binder, film-former, and moisture-retention agent in food, pharmaceuticals, cosmetics, and construction materials.

Understanding HPMC Safety An Overview

- In addition to these factors, the market share of redispersible polymer powders is also influenced by factors such as pricing, product quality, distribution channels, and customer service. Companies that can offer competitive pricing, superior product quality, and excellent customer service are more likely to gain market share and maintain their position as industry leaders.

Hydroxypropyl Methylcellulose is globally known as “Hypromellose” and manufactured by chemically made polymer cellulose. It is considered safe for normal human consumption and is commonly used as an option instead of gelatin because of its vegetarian source and its physical appearance to gelatin.

Important physical properties to examine the quality of a dispersant are the surface (or interfacial) tension, interfacial strength and gelling temperature of its aqueous solution. These characteristics of hydroxyethyl cellulose are suitable for the polymerization or copolymerization of synthetic resins.

In conclusion, redispersible polymer powders play a pivotal role in enhancing the performance of various construction materials. Understanding the different types of RDPs and their specific applications allows manufacturers to make informed choices, ensuring that the end products meet the desired performance standards. As the construction industry continues to evolve, RDPs will remain integral to developing innovative materials that cater to dynamic building needs.

China has emerged as one of the leading suppliers of HPMC, thanks to its advanced manufacturing technologies, abundant natural resources, and cost-effective production processes. The country hosts several well-established HPMC manufacturers capable of producing high-quality products that meet international standards. These suppliers not only cater to the domestic market but also export HPMC to various regions around the world, including North America, Europe, and Southeast Asia.

What is HPMC?

5. Agricultural Applications HPMC sheets are also finding their way into agriculture. They can be used in seed coatings and plant growth media, providing a controlled release of nutrients and protecting seeds from environmental stressors.

In conclusion, HPMC Limited exemplifies the principles of quality, innovation, and collaboration. Its commitment to excellence in manufacturing, customer satisfaction, and sustainability sets it apart in a competitive marketplace. As HPMC Limited continues to evolve and adapt, it remains focused on its core values, ensuring that it not only meets the current needs of its customers but also anticipates future challenges and opportunities. With a strong foundation and an unwavering commitment to quality, HPMC Limited is well-positioned for continued success in the global arena.

What is HPMC?

The Role of HPMC Importers

In personal care and cosmetics, HPMC is valued for its film-forming and viscosity-modifying properties. It is commonly found in various products, including shampoos, conditioners, lotions, and facial creams. HPMC assists in creating a smooth and creamy texture while providing stability to emulsions. Its ability to retain moisture helps in formulating hydrating skin and hair care products. Furthermore, HPMC is used in the formulation of adhesives for contact lenses, ensuring ease of wearing and comfort by maintaining moisture around the lenses.

Character

The incorporation of HPMC in wall putty formulations offers numerous benefits that enhance both the performance and application of this essential construction material. From improved workability and adhesion to reduced shrinkage and extended open time, HPMC helps create a smooth, durable surface that meets the demands of modern building requirements. As the construction industry continues to focus on sustainability and performance, the importance of HPMC in wall putty applications cannot be overstated. Its ability to improve the quality of finishes makes it a valuable asset in achieving professional results in interior and exterior wall treatments.

Another noteworthy application of Ashland Hydroxyethyl Cellulose is in the food industry, where it serves as a food additive. Due to its thickening and gelling properties, HEC can enhance the texture and stability of various food products such as sauces, dressings, and desserts. It aids in achieving the desired viscosity and can also help emulsify oil and water-based ingredients, improving the overall consistency of food items.

Redispersible polymer powders (RDPs) are a class of materials that have gained significant attention in the construction and building industry due to their unique properties and versatility. These fine, free-flowing powders are produced by the spray-drying of aqueous polymer dispersions and have the ability to rehydrate and redisperse when mixed with water. This article explores the composition, applications, and advantages of redispersible polymer powders, highlighting their pivotal role in modern construction materials.

When searching for hydroxyethyl cellulose, consider the following factors to ensure you make an informed purchase

What Is HPMC? Hydroxypropyl Methylcellulose

Conclusion

Many pharma companies use hypromellose for controlled release and especially for matrix tablet formulations. You may be wondering what your options are when it comes to HPMC products – especially if you are seeking something that you can market to your customers as label-friendly and sustainable. In this guide, we will talk about the key things you need to know about hypromellose.

1. Pharmaceutical Grades In the pharmaceutical industry, HPMC is often used as an excipient in tablet formulations. It acts as a binder, controlling the release of active ingredients. For instance, low viscosity HPMC grades are used in immediate-release formulations, while high viscosity grades are utilized for controlled-release applications.

hpmc grades pdf

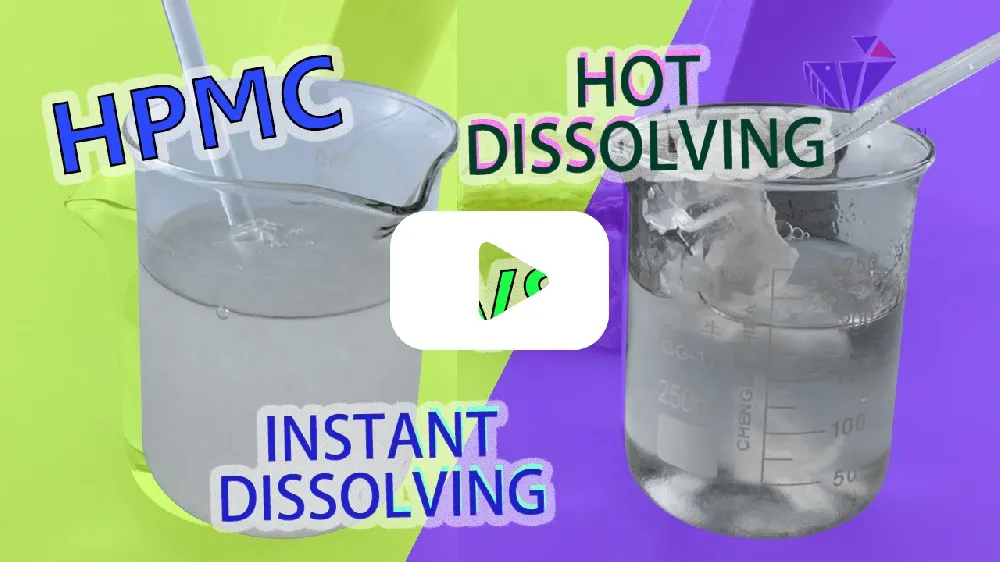

The solubility of HPMC is largely dependent on its molecular weight and the degree of substitution—the ratio of methoxy and hydroxypropyl groups present in the molecule. HPMC is typically soluble in cold or hot water, forming a clear and viscous solution. The solubility varies with the concentration of HPMC; higher concentrations can lead to gel-like solutions or pastes rather than true solutions.

- Eco-Friendly As a biodegradable product, HPMC aligns with modern sustainability goals, appealing to environmentally conscious consumers and manufacturers alike.

When evaluating potential manufacturers, it is essential to consider their experience in the industry, the variety of HPMC grades they offer, and their ability to meet specific customer requirements. A well-established manufacturer will have a track record of delivering consistent products and maintaining strong relationships with their clients.

On the other hand, smaller firms focused exclusively on HPMC production may exhibit stock volatility based on market conditions, production capacity, and customer contracts. Companies that manage to secure long-term agreements with key clients in construction and pharmaceuticals often see a more stable stock performance as they are able to predict revenue streams more accurately.

Applications of HPMC in Pharmaceuticals

In addition to improved adhesion, RDP contributes to flexibility and improved workability. Cement-based products with RDP exhibit enhanced flexibility, reducing the risk of cracking and damage under stress. This property is critical in construction, where materials must withstand temperature fluctuations and mechanical stress. Furthermore, RDP provides a smoother texture, which facilitates easier application and finishing of the material.

redispersible polymer powder wiki

The Role of HPMC in Various Industries

Understanding HPMC Powder Properties, Applications, and Benefits

- Ceramic Tiles Ideal for both wall and floor installations, providing reliable adhesion and durability.

Hydroxypropyl Methyl Cellulose Manufacturers An Overview

Conclusion

Moreover, HPMC is recognized for its environmentally friendly characteristics. As a plant-derived product, it is biodegradable and non-toxic, making it a sustainable choice for manufacturers aiming to reduce their environmental footprint. This attribute aligns with the growing consumer demand for eco-friendly products and practices, leading many industries to incorporate HPMC into their formulations.

In the food industry, HPMC is used as a thickening and stabilizing agent. Its solubility in water allows it to be easily integrated into various food products, where it can improve texture, enhance mouthfeel, and provide emulsion stability. For instance, HPMC is often found in gluten-free baked goods, where it helps retain moisture and mimic the texture that gluten provides in traditional recipes. The solubility characteristics of HPMC also facilitate the creation of low-calorie food products by providing bulk and viscosity without contributing significant calories.

hpmc solubility in water

Another important factor that can affect the price of MHEC is the brand or manufacturer. Some manufacturers are known for producing high-quality MHEC that commands a premium price, while others may offer more budget-friendly options. It is important to weigh the cost against the quality and performance of the product to ensure that you are getting the best value for your money.

In the pharmaceutical industry, HPMC is used as a binder, disintegrant, and coating agent for tablets and capsules. It improves the tablet hardness, disintegration time, and dissolution rate of drugs, leading to improved bioavailability and efficacy.

In addition to its pharmaceutical uses, HPMC is a crucial ingredient in the food industry. It functions as a thickening agent, stabilizer, and emulsifier, enhancing the texture and mouthfeel of various food products. It is often found in sauces, dressings, and baked goods, where it imparts desired viscosity without altering the flavor profile. Moreover, HPMC is compatible with gluten-free diets, making it a popular choice for formulating gluten-free products.

cellulose ether hpmc

HPMC effectively mitigates shrinkage and cracking issues often encountered with traditional wall putty formulations. When the putty dries, it can shrink and develop cracks, especially in changing environmental conditions. The presence of HPMC helps maintain moisture, allowing the putty to dry evenly and reducing the likelihood of defects. This property ensures a durable and aesthetically pleasing finish.

2. Construction In the building industry, HPMC is added to cement, plaster, and tile adhesives for increased adhesion, workability, and fluid retention. It improves the performance of construction materials, making them more durable and efficient.

The HPMC Manufacturing Process