fabricant de forage

The hammer itself can be operated using a pneumatic or hydraulic system, with hydraulic hammers being the preferred choice in most cases due to their consistent performance and reliability. The drill bit used is often designed specifically for marine environments, featuring reinforced materials and cutting edges optimized for hard substrates.

Advantages of DTH Hammer Drilling

- البناء تستخدم في تشغيل الأدوات الهوائية مثل المثاقب المفاجئة والمفكات، مما يؤدي إلى زيادة كفاءة العمل.

The reason:

Inlet valve is not open or has silted

Suction line resistance is too high or blocked

Suction height is too high

Inlet valve is not open or has silted

Suction line resistance is too high or blocked

Suction height is too high

Q: What sets self-priming slurry pump solutions apart from traditional pumps?

A: Self-priming slurry pump solutions offer superior priming capabilities, eliminating the need for external priming sources and simplifying operation.

Q: How do self-priming slurry pump solutions enhance efficiency in industrial processes?

A: By handling abrasive materials with ease, reducing downtime, and optimizing performance, self-priming slurry pump solutions drive efficiency and productivity in various industries.

Q: Are self-priming slurry pump solutions suitable for harsh environments?

A: Yes, self-priming slurry pump solutions are designed to withstand the rigors of challenging environments, making them ideal for industries such as mining, construction, and manufacturing.

Q: Can self-priming slurry pump solutions be customized to meet specific requirements?

A: Yes, manufacturers offer customized solutions that cater to the unique needs of industries, ensuring optimal performance and efficiency.

Q: How do self-priming slurry pump solutions contribute to cost savings for industries?

A: By reducing maintenance costs, minimizing downtime, and optimizing processes, self-priming slurry pump solutions help industries save money and improve their bottom line.

Q: What sets self-priming slurry pump solutions apart from traditional pumps?

A: Self-priming slurry pump solutions offer superior priming capabilities, eliminating the need for external priming sources and simplifying operation.

Q: How do self-priming slurry pump solutions enhance efficiency in industrial processes?

A: By handling abrasive materials with ease, reducing downtime, and optimizing performance, self-priming slurry pump solutions drive efficiency and productivity in various industries.

Q: Are self-priming slurry pump solutions suitable for harsh environments?

A: Yes, self-priming slurry pump solutions are designed to withstand the rigors of challenging environments, making them ideal for industries such as mining, construction, and manufacturing.

Q: Can self-priming slurry pump solutions be customized to meet specific requirements?

A: Yes, manufacturers offer customized solutions that cater to the unique needs of industries, ensuring optimal performance and efficiency.

Q: How do self-priming slurry pump solutions contribute to cost savings for industries?

A: By reducing maintenance costs, minimizing downtime, and optimizing processes, self-priming slurry pump solutions help industries save money and improve their bottom line.

It allows you to see what is underneath the tape, making it easier to accurately place and align It allows you to see what is underneath the tape, making it easier to accurately place and align

It allows you to see what is underneath the tape, making it easier to accurately place and align It allows you to see what is underneath the tape, making it easier to accurately place and align

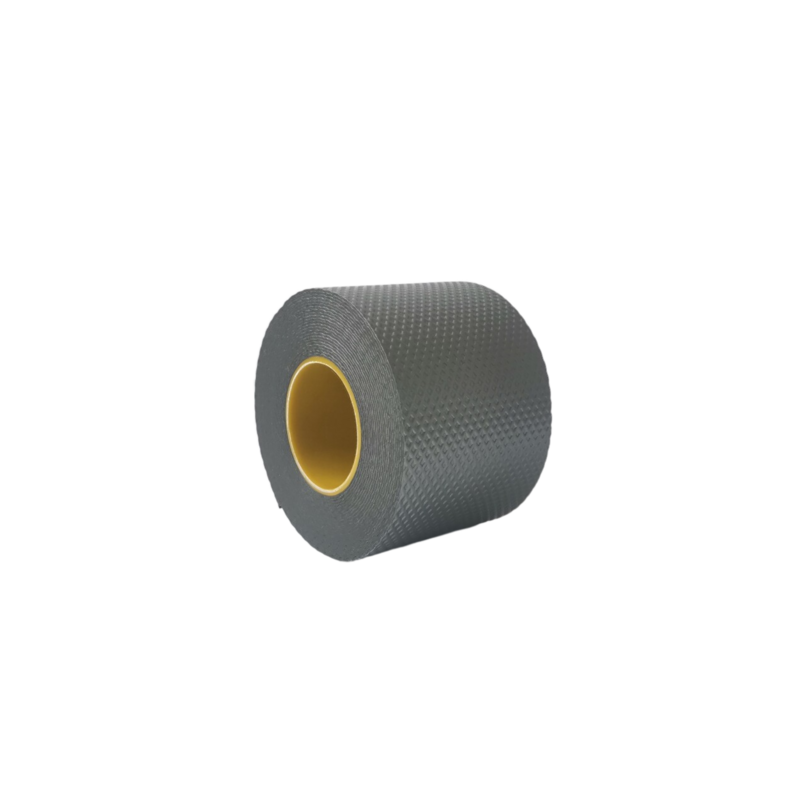

It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments

It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments