rubber lined slurry pumps

3. Acier inoxydable Pour des environnements particulièrement corrosifs, comme dans l’exploration en milieu marin, l'acier inoxydable est souvent la meilleure option. Bien qu'il soit généralement plus coûteux que l'acier au carbone, sa résistance à la corrosion justifie cet investissement.

Mars, often referred to as the Red Planet, has long fascinated scientists and space enthusiasts alike. One of the most intriguing aspects of Mars is its atmosphere, which is characterized by low pressure compared to that of Earth. Understanding the implications of low atmospheric pressure on Mars is crucial for various fields, including planetary science, astrobiology, and the future of human exploration.

In conclusion, understanding the various drilling materials and their applications is essential for successful drilling operations across multiple industries. From drill bits to drilling fluids, casing, and drill pipes, each component plays a vital role in determining the efficiency, safety, and overall success of the drilling process. As technology continues to evolve, innovations in drilling materials will likely lead to more efficient and safer drilling methods, ultimately benefiting not only the industries involved but also the environment and society as a whole. Investing in the right materials is not just a matter of operational efficiency, but also a critical step toward sustainable practices in drilling and resource extraction.

Additionally, submarine hammer drilling is a versatile technique, suitable for various applications, including the installation of underwater pipelines, foundations for offshore structures, and the recovery of geological samples for research and analysis. This adaptability makes it an essential tool in the fields of marine engineering, environmental research, and resource extraction.

Equipment and Technology

DTH hammer drilling is widely utilized in various sectors, including

Drilling equipment is essential in various sectors, including oil and gas, mining, construction, and environmental research. Each sector requires specialized machinery capable of performing specific tasks effectively. For instance, in the oil and gas industry, rotary drill rigs and downhole drilling tools are critical for accessing subterranean resources. In contrast, the mining sector demands heavy-duty equipment designed to penetrate solid rock and extract valuable minerals.

The reason:

Inlet valve is not open or has silted

Suction line resistance is too high or blocked

Suction height is too high

Inlet valve is not open or has silted

Suction line resistance is too high or blocked

Suction height is too high

Price and Availability

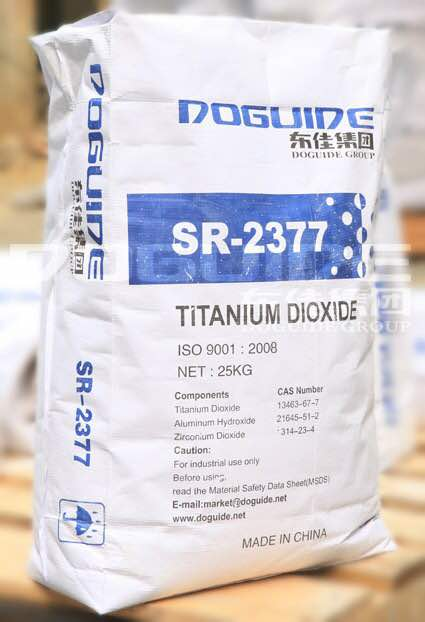

Price and Availability Preparation of the titanium solution This involves dissolving titanium ore or other titanium-containing compounds in a suitable solvent to form a concentrated solution Preparation of the titanium solution This involves dissolving titanium ore or other titanium-containing compounds in a suitable solvent to form a concentrated solution

Preparation of the titanium solution This involves dissolving titanium ore or other titanium-containing compounds in a suitable solvent to form a concentrated solution Preparation of the titanium solution This involves dissolving titanium ore or other titanium-containing compounds in a suitable solvent to form a concentrated solution