bombas de lama revestidas de borracha

Importance of Accurate Calculations

Types of Jaw Plates

Before each day's operation, refill the 29 grease points with grease.

2. Marine Construction When constructing offshore platforms, bridges, or wind farms, the stability of foundations is paramount. Hammer drilling provides a reliable method to secure pilings and conduct deep foundation work, ensuring that structures can withstand harsh marine conditions.

En conclusión, los chocks en los laminadores son componentes esenciales que desempeñan un papel crítico en la industria metalúrgica. Su capacidad para soportar altas cargas, proporcionar estabilidad y permitir ajustes precisos es fundamental para garantizar la calidad del producto final. A medida que la tecnología avanza, el futuro de los chocks también se vislumbra prometedor, con mejoras que continuarán impulsando la eficiencia y la sostenibilidad en los procesos de laminado. La atención al mantenimiento y la innovación en su diseño asegurarán que estos elementos vitales sigan funcionando eficazmente en una industria en constante evolución.

The 20mm drill rod finds a wide range of applications across different sectors. In the geological and mining industries, these rods are used for exploratory drilling and core sampling. Drillers can obtain valuable subsurface samples, allowing geologists to analyze mineral composition and assess potential mining projects. The precise and efficient nature of the 20mm drill rod enhances the accuracy of these assessments, ultimately leading to better-informed decisions.

02 REGULAR INSPECTION

Before attempting any repairs, carefully assess the extent of the chipping. Small chips may not affect the functionality of the enamel pot,but larger chips could expose the underlying metal, potentially leading to rust and further deterioration.

You can use French skillets to prepare various foods, including fried and boiled dishes. You can also use these skillets for poaching liquids or shallow frying.

Yes. Like cast iron, a carbon steel pan can handle very high heat and go from the stovetop or grill to the oven without damaging the pan.

It's also resistant to chipping, cracking, and rust, ensuring long-lasting performance It's also resistant to chipping, cracking, and rust, ensuring long-lasting performance

It's also resistant to chipping, cracking, and rust, ensuring long-lasting performance It's also resistant to chipping, cracking, and rust, ensuring long-lasting performance kitchen aid cast iron grill pan. Moreover, the cast iron material makes it compatible with all stovetops, including induction, oven, broiler, and even campfire, offering unparalleled versatility.

kitchen aid cast iron grill pan. Moreover, the cast iron material makes it compatible with all stovetops, including induction, oven, broiler, and even campfire, offering unparalleled versatility.Similarly to cast iron, carbon steel pans need to be seasoned before use (though some, like ours, do come preseasoned). As if these pans weren’t already versatile enough, carbon steel is also safe to use on the grill as well as over an open flame.

In conclusion, while French skillets and frying pans are made of stainless steel, the difference in their design lies in the height of their sides.

Stainless steel frying pans are also great for high-heat cooking and ideal for searing and browning food. They are also safe for use on all stovetops, including induction.

Because of the smooth enamel surface, food residue doesn’t stick as tenaciously, and a simple scrub with a soft brush and some soap usually suffices to get it clean Because of the smooth enamel surface, food residue doesn’t stick as tenaciously, and a simple scrub with a soft brush and some soap usually suffices to get it clean

Because of the smooth enamel surface, food residue doesn’t stick as tenaciously, and a simple scrub with a soft brush and some soap usually suffices to get it clean Because of the smooth enamel surface, food residue doesn’t stick as tenaciously, and a simple scrub with a soft brush and some soap usually suffices to get it clean enamel coated cast iron griddle. However, it's important to avoid jumping between extreme temperatures to prevent cracking the enamel.

enamel coated cast iron griddle. However, it's important to avoid jumping between extreme temperatures to prevent cracking the enamel.The main difference between a skillet and a pan is their shapes. A skillet has shorter, curved sides, while a sauté pan has straight, vertical sides.

In 1934, Le Creuset first debuted their iconic French skillet to the United States as a component of their “Art Deco” collection.

The non-stick coating also prevents food from burning, reducing the chances of unwanted smoke and burnt flavors The non-stick coating also prevents food from burning, reducing the chances of unwanted smoke and burnt flavors

The non-stick coating also prevents food from burning, reducing the chances of unwanted smoke and burnt flavors The non-stick coating also prevents food from burning, reducing the chances of unwanted smoke and burnt flavors non stick enamel cookware.

non stick enamel cookware.

According to the U.S. Department of Agriculture, these companies had no interest in quality control or strong market demand and made their products available at low prices.

A good choice, especially for heavily used cookware, is a tri-ply or five-ply combination of stainless steel and aluminum (or hard-anodized aluminum). Stainless steel provides a durable surface, providing excellent heat retention and safety. Interior layers of aluminum ensure even heat distribution. All these work together to create the ideal cooking base, whether you’re using a skillet or sauté pan.

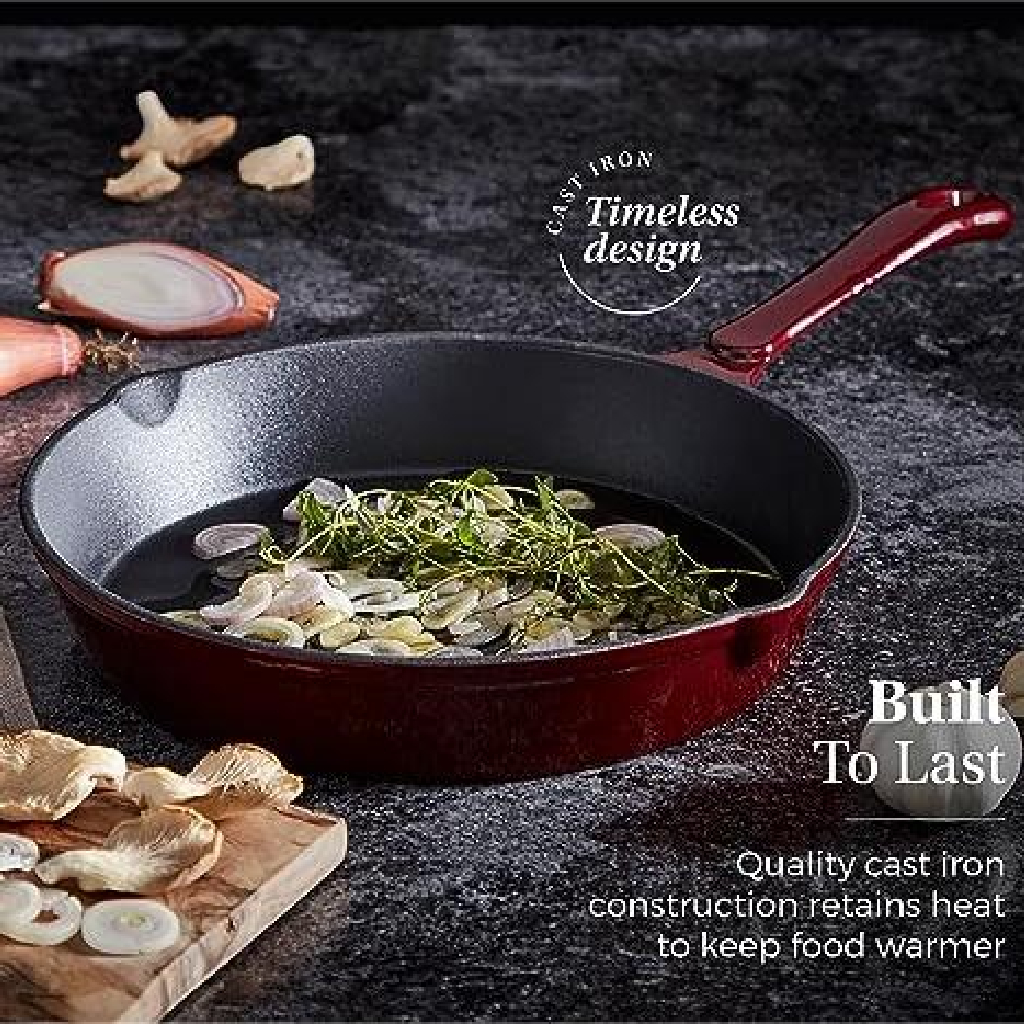

iron cast enamel cookware. Its thermal stability allows it to retain heat long after being removed from the heat source, keeping food warm during mealtime.

iron cast enamel cookware. Its thermal stability allows it to retain heat long after being removed from the heat source, keeping food warm during mealtime.