\]

Outerwear Production

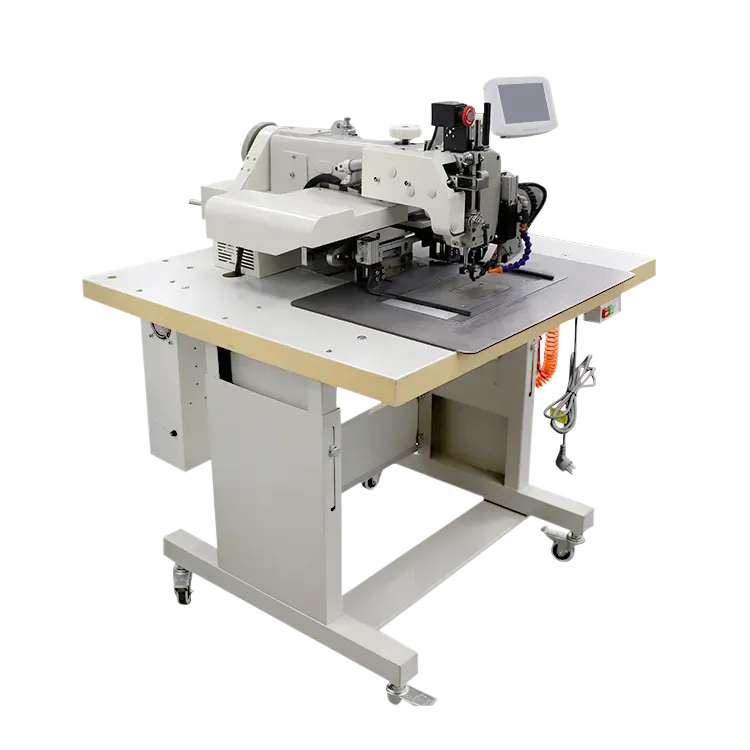

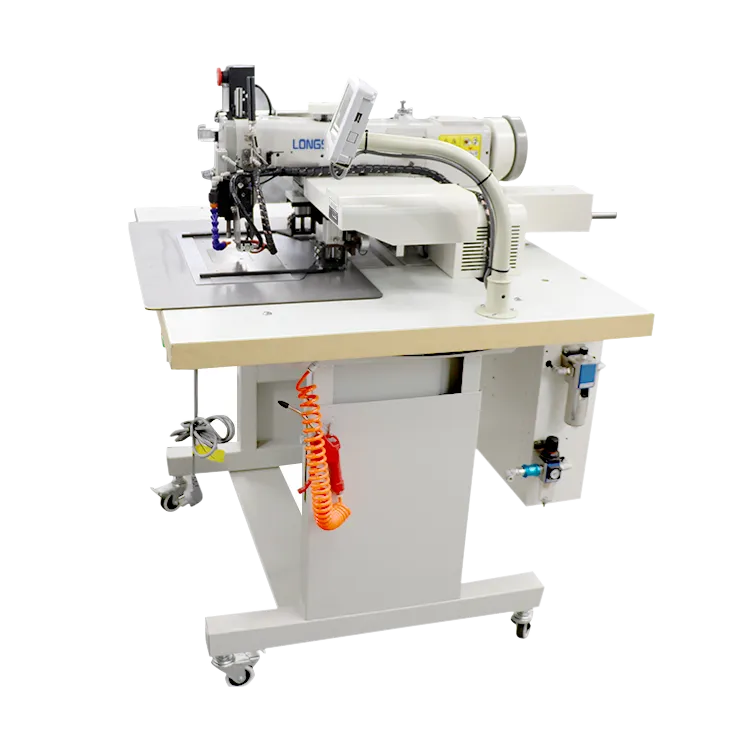

When it comes to sewing and stitching machines, one of the most powerful and versatile options available is the long arm stitching machine. This specialized machine is designed for larger projects and offers a variety of benefits that make it an essential tool for serious sewers and quilters.

The Needle Feed Sewing Machine Revolutionizing Textile Production

Sewing has been an integral part of human civilization for centuries, evolving remarkably with technological advancements. Among the many tools employed by seamstresses and tailors, the lockstitch sewing machine stands out as one of the most significant. This fundamental piece of equipment has revolutionized the way we create garments, upholstery, and various textile products, marrying functionality with efficiency.

Additionally, the zigzag stitch is particularly beneficial when working with stretch fabrics, such as knits and spandex. It allows the fabric to maintain its elastic properties, which is essential for achieving a flattering fit in garments such as leggings and fitted tops.

Where to Buy

The lock stitch machine is a fundamental piece of equipment in sewing, widely used in the textile and garment industries. It is recognized for its durability and versatility, making it indispensable for both professional garment manufacturing and home sewing.

One of the beauties of single needle top stitching is its versatility. It can be used in various garment types, from traditional denim jeans to delicate blouses. In denim, top stitching not only reinforces the seams but also adds an iconic style element, often seen in the form of contrasting thread colors. For blouses, a delicate top stitch can accentuate collar edges or cuffs, enhancing their overall design.

Understanding Your Sewing Needs

Lock stitch is a sewing technique that involves interlocking two threads—one from the needle and the other from the bobbin—to create a strong seam. This method is particularly advantageous for securing the seams of jumbo bags because it provides a tight, secure closure that can withstand significant tension and pressure. Unlike other stitching methods, lock stitch produces a consistent and uniform seam, reducing the likelihood of bag failure due to seam separation.

What is a Serger Machine?

In the world of textiles and fashion, sewing machines have long been an essential tool for both hobbyists and professionals. Among the various types of sewing machines available today, the computerized sewing machine stands out for its advanced features and capabilities. But what exactly does a computerized sewing machine do, and how does it enhance the sewing experience?

2. Improved Load Capacity With the added strength of lock stitches, jumbo bags can handle greater loads without compromising integrity. This means manufacturers can safely transport larger quantities of materials, improving efficiency in logistics and reducing transportation costs.

leather canvas sewing machine. The presser foot can also be adjusted to accommodate different thicknesses of material, allowing for flexibility in the types of projects that can be completed with the machine.

3. Metal Components Durability is crucial in heavy-duty sewing machines. Opt for machines with a metal frame and metal internal parts, as these are more robust than their plastic counterparts. A heavy metal base not only enhances stability during sewing but also prolongs the machine's life span.

Conclusion

what are heavy duty sewing machines used for

User-Friendly Features

1. Precision and Control The swinging movement of the needle grants users greater control over their stitching, allowing for intricate designs that require a steady hand and attention to detail. This precision makes them ideal for custom work and high-quality garments.

- Price While industrial machines can be more expensive than domestic ones, the investment often pays off in terms of durability and performance. Compare prices across different suppliers to ensure you get the best value for your investment.

A serger machine, also known as an overlock machine, is designed to stitch and finish the edges of fabric in a single pass. Unlike traditional sewing machines, sergers use multiple threads to create a secured seam and can simultaneously trim excess fabric. This unique functionality not only saves time but also enhances the quality of the final product, making sergers an essential tool for anyone serious about garment construction or fabric crafting.

In conclusion, the floating foot sewing machine has redefined the sewing landscape by providing enhanced precision, flexibility, and user-friendly features. Whether you are a budding enthusiast or a seasoned professional, integrating this innovative sewing tool into your crafting toolkit can significantly elevate your sewing experience. As technology continues to evolve, it’s exciting to foresee what other advancements will shape the future of sewing, but for now, the floating foot machine stands out as a definitive asset in the world of textiles. Embracing this technology not only streamlines the sewing process but also opens up endless possibilities for creativity and craftsmanship in every stitch.

In the realm of sewing, details matter. One of the techniques that elevate garments from ordinary to extraordinary is the single needle top stitch. Often underappreciated, this technique not only serves a functional purpose but also adds a touch of sophistication and style to any piece.

5. Presser Foot A walking foot is essential for heavy fabrics as it ensures even feeding of the layers and helps prevent puckering.

4. Time Efficiency By combining the capacity to handle larger projects with the versatility of zigzag stitching, these machines can significantly reduce sewing time. Sewists can complete more projects in less time, making them ideal for both professional use and hobbyists looking to maximize their crafting experience.

When sewing with a two needle stitch, it is advisable to practice on scrap fabric before working on the final project. This helps in adjusting settings and familiarizing oneself with the machine’s behavior when using two needles. Once comfortable, the seamstress can confidently move on to larger projects, exploring various designs and applications.

3. Needle Size Heavy-duty sewing machines can accommodate larger needles, which are necessary for working with thick materials. Look for machines that allow for a variety of needle sizes, allowing you to choose the right one for your specific vinyl project.

One of the primary functions of a serger is to finish the raw edges of fabric. The machine uses multiple threads to create a tight stitch around the edges, which helps prevent fraying. This is especially useful when working with knit fabrics, which can easily unravel if not properly finished. By serging the edges, you can ensure your garments have a polished and professional look, saving you from the hassle of having to zigzag stitch or use bias tape on each project.