...

2025-08-14 03:47

2332

...

2025-08-14 03:12

2751

...

2025-08-14 03:09

378

...

2025-08-14 03:06

1612

...

2025-08-14 03:05

2245

...

2025-08-14 02:54

259

...

2025-08-14 02:41

1326

...

2025-08-14 02:39

2910

...

2025-08-14 02:34

749

...

2025-08-14 02:01

789

- (Z)-8-Pentadecenal

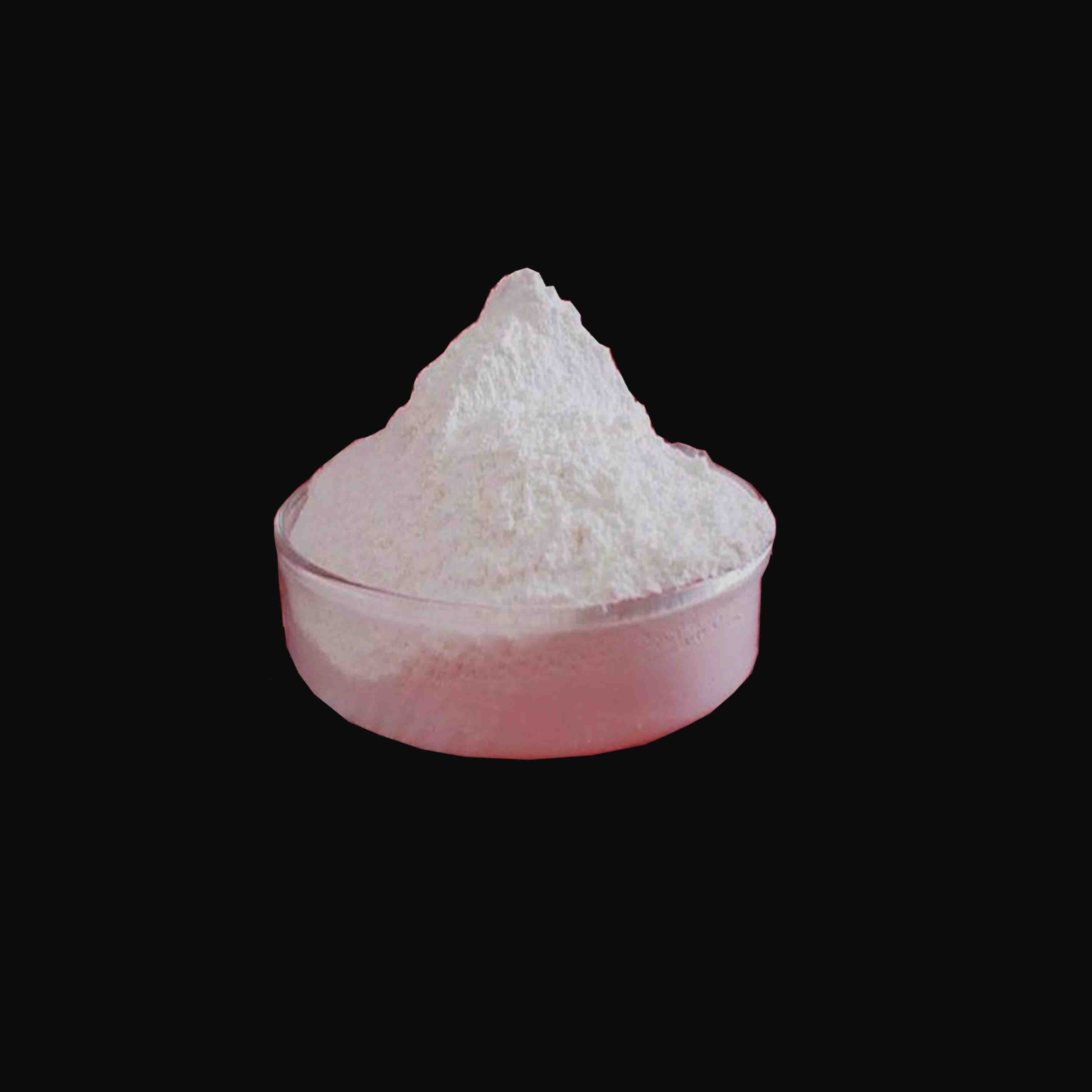

- Titanium dioxide is a widely used white pigment in various applications such as paint, coatings, plastics, paper, and even food products. It is known for its brightness and high refractive index, making it the preferred choice for imparting opacity and whiteness in many products.

- Another advantage of TIO2 is its excellent stability and resistance to fading. Unlike some other pigments, TIO2 does not degrade or change color over time, ensuring that your products maintain their quality and appearance for longer periods. This makes it an ideal choice for products that are exposed to sunlight or harsh environmental conditions.

Method of producing improved lithopone

105°C volatile matter, %

china rc 823 titanium dioxide. By adjusting the particle size distribution, manufacturers can achieve the desired level of opacity, gloss, and dispersion in their formulations.

However, they did find that minor levels of 0.01% were absorbed by immune cells — known as gut-associated lymphoid tissue — and may be delivered to other organs. Currently, it’s unknown how this may affect human health (17Trusted Source).

The leaching of the electrolytic zinc acid leaching slag: 1500 ml of ammonia-ammonium sulphate solution is used as the ammonia immersion liquid, wherein the ammonia concentration is 6. Omol / ammonium sulfate molar concentration is 0. 9mol / L, added per cubic meter of ammonia immersion liquid 0. 075kg of sodium dodecylbenzenesulfonate, 0. 45kg of sodium fluorosilicate, 0.75kg of dicyandiamide. 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 。 %), added to the above ammonia-ammonium sulfate immersion liquid for three-stage leaching, each leaching time is 2 hours, after solid-liquid separation, 1450ml final immersion liquid (taken away in the remaining liquid slag), zinc leaching The rate of 90. 02%; the final solution containing zinc 65. 6g / L; containing S0 4 2 - 69. 64g / L ;

By adopting sustainable practices, manufacturers can not only reduce their environmental impact but also improve their reputation and appeal to environmentally conscious customers By adopting sustainable practices, manufacturers can not only reduce their environmental impact but also improve their reputation and appeal to environmentally conscious customers

By adopting sustainable practices, manufacturers can not only reduce their environmental impact but also improve their reputation and appeal to environmentally conscious customers By adopting sustainable practices, manufacturers can not only reduce their environmental impact but also improve their reputation and appeal to environmentally conscious customers titanium dioxide rutile manufacturers.

titanium dioxide rutile manufacturers.The scattering efficiency of pigment particles in a system is governed by two key properties.

O-C vibrations present in the vitamin C. The intense band at 1672 cm−1 is attributed to the C = O stretching in the lactone ring while the peak at 1026 cm−1 is ascribed to the stretching vibration Ti-O-C. Wide bands at 3880–3600 cm−1 are related to stretching vibration OH groups, but those disappear in the modified nanoparticles spectrum. These observations confirm the interactions between the P25TiO2NPs and the vitamins

O-C vibrations present in the vitamin C. The intense band at 1672 cm−1 is attributed to the C = O stretching in the lactone ring while the peak at 1026 cm−1 is ascribed to the stretching vibration Ti-O-C. Wide bands at 3880–3600 cm−1 are related to stretching vibration OH groups, but those disappear in the modified nanoparticles spectrum. These observations confirm the interactions between the P25TiO2NPs and the vitamins