bombas de lama cerâmica

At its core, submarine hammer drilling employs a powerful hammer mechanism to drive a drill bit into the seabed. The system utilizes both air and water pressure to deliver repeated impacts on the drill bit, which enables it to break through hard rock formations or sediments that might hinder installation efforts for marine infrastructure. The design of the hammer ensures that the energy is efficiently transmitted to the drill bit, allowing it to operate at significant depths.

Moreover, the wear and tear of jaw plates can lead to decreased efficiency, increased downtime, and heightened operational costs. Regular monitoring and timely replacement of worn-out jaw plates are essential to maintain optimal performance and reduce the risk of equipment failure.

Teshkilot va Asboblar Burg'ulash Vositalarining Narxlari

Increased efficiency and productivity

- Reduced downtime and maintenance costs

- Enhanced performance in challenging environments

Increased efficiency and productivity

- Reduced downtime and maintenance costs

- Enhanced performance in challenging environments

If the wheel is stuck or difficult to remove, you may need to use a hammer or mallet to gently tap it free If the wheel is stuck or difficult to remove, you may need to use a hammer or mallet to gently tap it free

If the wheel is stuck or difficult to remove, you may need to use a hammer or mallet to gently tap it free If the wheel is stuck or difficult to remove, you may need to use a hammer or mallet to gently tap it free Applications of

Applications of This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments

This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments

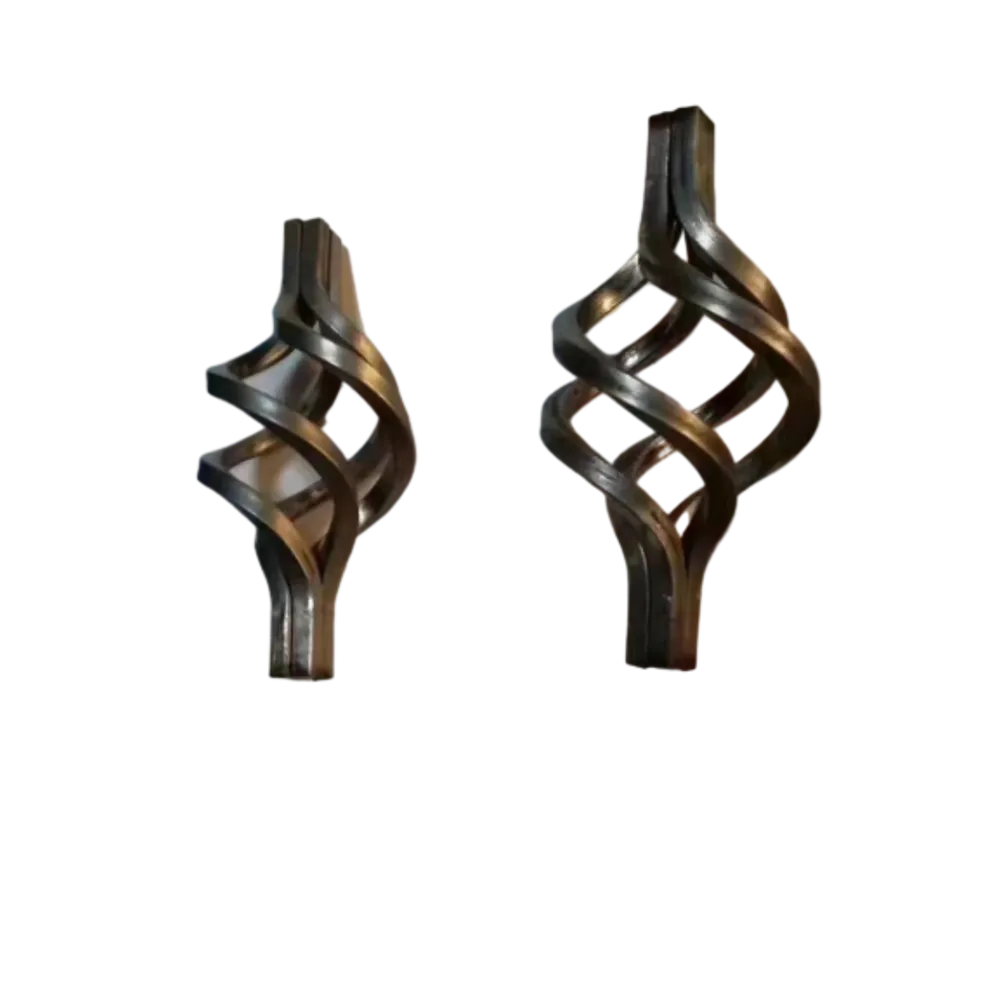

The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme

The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme