The Versatile Applications of Red Insulation Tape

Conclusion

fire seal tape. It can be applied around electrical outlets, piping, and HVAC ducts to prevent the spread of fire through these vulnerable areas. It can also be used to seal gaps around doors and windows, helping to create a barrier against fire and smoke intrusion.

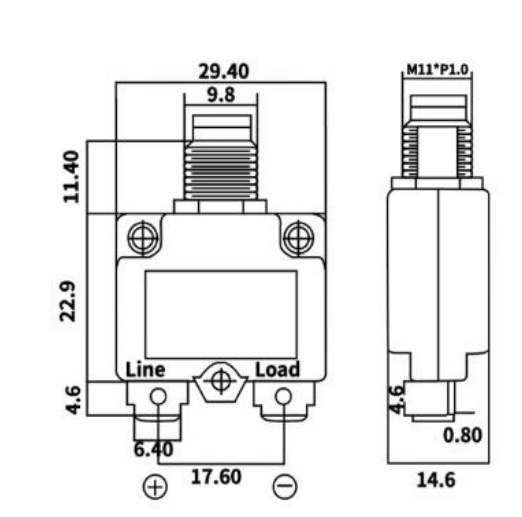

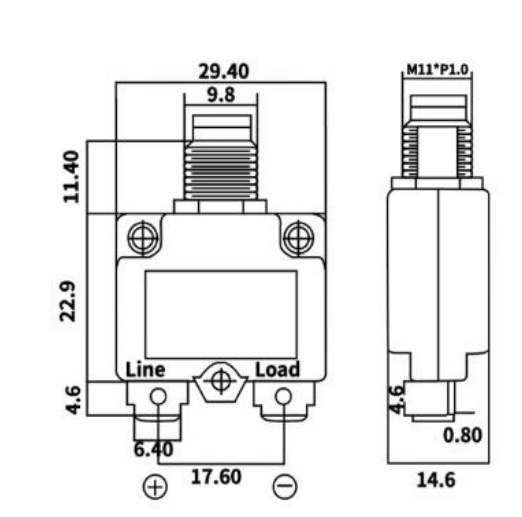

fire seal tape. It can be applied around electrical outlets, piping, and HVAC ducts to prevent the spread of fire through these vulnerable areas. It can also be used to seal gaps around doors and windows, helping to create a barrier against fire and smoke intrusion.Each type of control box plays a role in its respective field, acting as a tailored solution to control and protect electrical systems.

Butyl rubber waterproofing is a popular method used to protect various surfaces from water damage. This type of waterproofing involves the application of a special butyl rubber compound that creates a durable and impermeable barrier against moisture. Whether used in construction projects, industrial applications, or even in residential settings, butyl rubber waterproofing offers a reliable solution for preventing water intrusion and preserving the integrity of buildings and structures.

Weather stripping plays a crucial role in maintaining the energy efficiency of homes and buildings. Among the various types of weather stripping materials, butyl rubber stands out due to its flexibility, durability, and excellent adhesion properties. This article explores the significance of butyl weather stripping, its advantages, and how to properly apply it in your home or office.

To use the tape, simply stretch it around the material you are trying to repair. As you wrap the tape in a circular motion, it begins to seal and “fuse” itself to the material. The most common forms of self-fusing / self-amalgamating tapes are made of silicone rubber (though other types also exist). They are designed to create a strong, seamless, rubbery, waterproof, and electrically insulating layer.

The Importance of Red and White Floor Marking Tape

Conclusion

One of the most significant advantages of butyl rubber is its low permeability to air and other gases. This attribute is particularly valuable in applications where maintaining an airtight seal is critical. Additionally, butyl rubber is resistant to UV radiation, oxidation, and aging, allowing it to withstand harsh environmental conditions without degrading.

In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives

In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives sealing tape for water leaks. It's also an excellent solution for hard-to-reach areas where conventional repair methods may prove challenging.

sealing tape for water leaks. It's also an excellent solution for hard-to-reach areas where conventional repair methods may prove challenging.One of the key selling points of silicone self-adhesive tape is its remarkable versatility in the realm of repairs. It is designed to be used in a variety of situations, making it a go-to solution for both professionals and DIY enthusiasts. Here are some of the common applications:

The primary difference between electrical and duct tape is their composition and material. Electrical tape is made from plastic vinyl or PVC, giving it a smooth and stretchy texture. Electrical tape is heat resistant and designed specifically for safely insulating electrical wires and materials that conduct electricity.

Repair Needs: Assess the nature and extent of your repair requirements. Each tape is best suited for different types of repairs.