- Pressure Control Drilling fluids help balance the pressure exerted by subsurface formations, preventing blowouts.

...

2025-08-14 20:42

2225

...

2025-08-14 20:20

243

...

2025-08-14 19:35

2668

...

2025-08-14 19:31

2373

...

2025-08-14 19:11

453

...

2025-08-14 18:59

2647

...

2025-08-14 18:55

929

...

2025-08-14 18:49

2464

...

2025-08-14 18:49

1784

...

2025-08-14 18:26

2119

Their non-conductive properties make them perfect for this application, preventing short circuits and ensuring safety Their non-conductive properties make them perfect for this application, preventing short circuits and ensuring safety

Their non-conductive properties make them perfect for this application, preventing short circuits and ensuring safety Their non-conductive properties make them perfect for this application, preventing short circuits and ensuring safety square rubber gasket.

square rubber gasket. Mechanical seals, on the other hand, use a set of rotating and stationary components to create a seal, while labyrinth seals have multiple barriers to prevent oil leakage Mechanical seals, on the other hand, use a set of rotating and stationary components to create a seal, while labyrinth seals have multiple barriers to prevent oil leakage

Mechanical seals, on the other hand, use a set of rotating and stationary components to create a seal, while labyrinth seals have multiple barriers to prevent oil leakage Mechanical seals, on the other hand, use a set of rotating and stationary components to create a seal, while labyrinth seals have multiple barriers to prevent oil leakage retainer oil seal.

retainer oil seal.4. SHAFT SPEED: As different shafts move at different speeds you need to consider the runout, the housing bore, and oil type being sealed. Ensure you select a seal that will not suffer from abrasions or spiralling.

Excellent high and low temperature resistance

14x24x6 oil seal. They often feature a metal case for added strength and durability, with a flexible lip that seals against the rotating shaft. In the context of a 14x24x6 oil seal, its compact design makes it suitable for use in compact or confined spaces, prevalent in many industrial applications.

14x24x6 oil seal. They often feature a metal case for added strength and durability, with a flexible lip that seals against the rotating shaft. In the context of a 14x24x6 oil seal, its compact design makes it suitable for use in compact or confined spaces, prevalent in many industrial applications.5. Sealing the grease container when not in use reduces the risk of contamination.

Other maintenance factors, such as

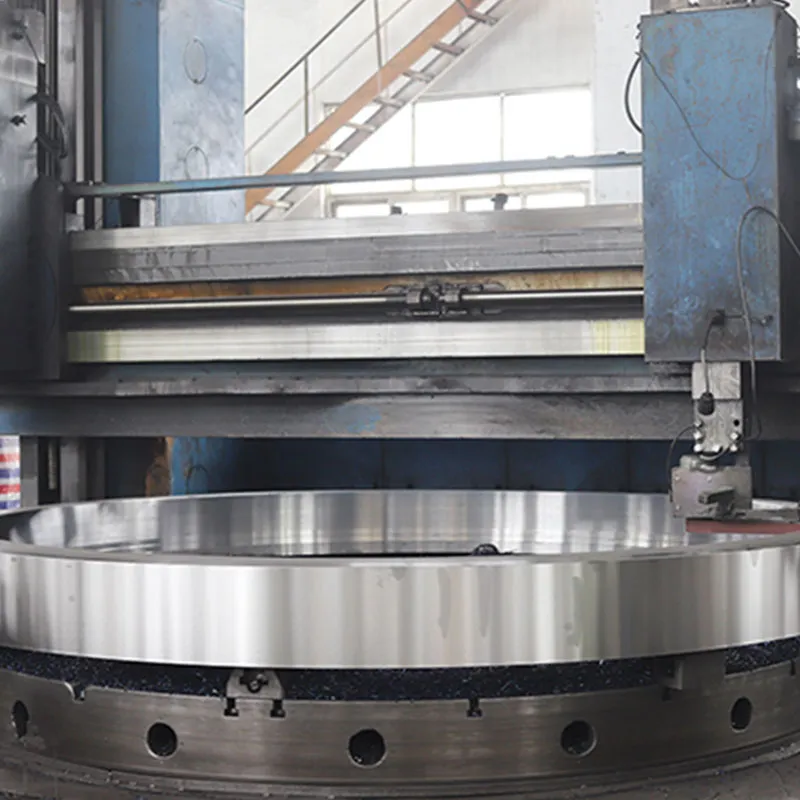

Rotary Wheel Of Auto Parts

What are Oil Seals?

Notes

1) ISO: International Organization for Standardization

2) 2) JIS: Japanese Industrial Standard

Longer seal life can be expected with shafts having a Rockwell (RC) hardness of 30 or more. When exposed to abrasive contamination, the hardness should be increased to RC 60.

The History and Applications of Oil Seals

The cover is fixed by nuts or bolts on top, or by screws round the edge. Loosen them all and remove them with their washers. If there are several oil-sealing washers under each fixing, note their order.