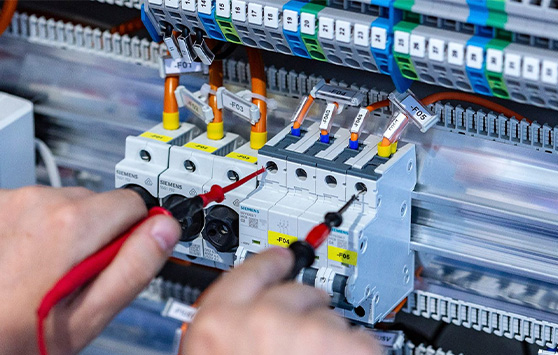

Electricians have critical jobs. Keeping our world powered requires concentration, knowledge and skill. Some of the most dangerous work is done by electricians working on medium and high voltage applications. Ethylene propylene and silicone rubber electrical tapes have the highest dielectric rating of electrical tapes made by 3M and are a trusted product in the toolbox of most medium and high voltage linemen and installers. With proper wrapping, their self-fusing properties help to eliminate voids in critical areas that may cause catastrophic failures .

. Apply the tape firmly over the leak, smoothing out any wrinkles or bubbles as you go. Finally, turn on the water supply slowly and check for any further leaks. If necessary, apply additional layers of sealing tape until the leak is completely sealed.

. Apply the tape firmly over the leak, smoothing out any wrinkles or bubbles as you go. Finally, turn on the water supply slowly and check for any further leaks. If necessary, apply additional layers of sealing tape until the leak is completely sealed.Bonus Round: Bike Connect

An automotive wiring loom wrap is a crucial component in any vehicle, as it serves to protect and organize the complex network of wires that power the vehicle's electrical systems. Without a proper wiring loom wrap, wires can become tangled, damaged, or exposed to the elements, leading to potential electrical malfunctions and safety hazards.

Motor lead insulation. In the case of low-voltage motor lead connections, the tape insulating process consists of connecting feeder cables to motor leads and arranging the conductors for easy wrapping. You should begin by wrapping two layers of varnished cambric tape, which is available with or without adhesive. For the adhesive type, apply with the adhesive side out for clean re-entry.

I hope you enjoyed this deep dive into the world of 3M Rubber Electrical Tapes. As a 3M expert, I can confidently say that these tapes are a game-changer in the electrical world. They're durable, flexible, and offer superior insulation, making them a must-have in every toolkit.

At its core, insulation tape is designed to insulate electrical wires and other conductive materials. The 50mm width makes it especially suited for larger cables and applications where broader coverage is necessary. Typically made from a blend of PVC and rubber, black insulation tape is favored for its durability and resistance to electric current, heat, and moisture. The black color also provides a sleek look that blends well with many surfaces, making it ideal for both visible and hidden applications.

When working on household electrical systems or DIY projects, using yellow insulation tape can help prevent short circuits and reduce the risk of electrical shock. Properly insulating wires can prolong the life of electrical components, making this tape indispensable for anyone handling electrical work.

In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives

In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives In emergencies, such as a burst pipe, it can prevent further water damage until a plumber arrives sealing tape for water leaks. It's also an excellent solution for hard-to-reach areas where conventional repair methods may prove challenging.

sealing tape for water leaks. It's also an excellent solution for hard-to-reach areas where conventional repair methods may prove challenging.In conclusion, yellow electrical tape is more than just a simple tool in an electrician's kit. Its multifunctional nature, spanning wire color-coding, insulation, temporary marking, and safety signaling, makes it an indispensable asset in electrical work. Whether you are a seasoned electrician or an enthusiastic DIYer, utilizing yellow electrical tape can enhance the safety, efficiency, and organization of any electrical project. Always remember that while tape can serve many roles, proper installation and adherence to safety standards are paramount in ensuring that all electrical work is conducted safely and effectively.

Self-fusing rubber tape, also known as self-vulcanizing tape, is made from a specialized rubber material that adheres to itself when stretched and wrapped around an object. Unlike traditional tapes, which rely on adhesive to stick to surfaces, self-fusing tape bonds through a process called vulcanization. This means that when the tape is applied under tension, the molecules of the rubber intermingle and create a solid, impermeable layer that is both waterproof and electrically insulating.