...

2025-08-16 02:53

257

...

2025-08-16 02:29

173

...

2025-08-16 02:21

2618

...

2025-08-16 01:43

1360

...

2025-08-16 01:30

587

...

2025-08-16 01:30

727

...

2025-08-16 01:10

1567

...

2025-08-16 00:49

2254

...

2025-08-16 00:38

1364

...

2025-08-16 00:30

1928

- 13. Impact-rated hammer drill bits Resistant to the shock of impact drivers, they are a must-have for professional contractors.

Molded FRP Fabrication - Moreover, the chemical resistance of fiberglass tanks extends to a multitude of chemicals, including acids, alkalis, solvents, and salts. This versatility allows them to be used in industries such as pharmaceuticals, petrochemicals, wastewater treatment, agriculture, and food processing, where the safe storage of diverse chemicals is paramount.

- In this comprehensive guide, we'll cover everything you need to know about tap drill bits, including their types, sizes, materials, and how to use them effectively. By the end of this article, you'll have a better understanding of these important tools and be able to select the right one for your specific needs.

- Fiberglass Products for Steel Smelting Plants A Comprehensive Guide

- Another benefit of impact driver drill bits is their versatility. These bits come in a variety of sizes and styles to suit different types of fasteners and materials. Whether you're working on a small woodworking project or a large construction job, there's an impact driver drill bit that's perfect for the task.

- In conclusion, rock drilling companies are the unsung heroes of our modern society, silently shaping our landscapes and contributing to our progress. Their work, often unseen, is vital to the global economy and our daily lives. As technology advances, these companies will undoubtedly continue to innovate, revolutionizing the way we access and utilize the earth's resources.

- Fiberglass, also known as glass-reinforced plastic, is a composite material made of tiny glass fibers embedded in a plastic matrix. This combination results in a strong, lightweight, and durable material that is ideal for use in sewage treatment facilities. One of the primary benefits of using fiberglass in sewage treatment is its resistance to corrosion and chemical reactions. Wastewater often contains harsh chemicals and pollutants that can corrode traditional materials like metal or concrete over time. However, fiberglass is impervious to these substances, making it an ideal choice for long-term use in sewage treatment facilities.

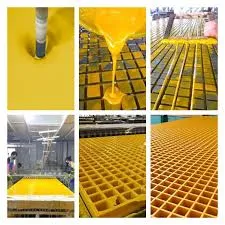

This curing process is crucial; it’s a bit like the alchemy that transforms raw ingredients into a delectable dish This curing process is crucial; it’s a bit like the alchemy that transforms raw ingredients into a delectable dish

This curing process is crucial; it’s a bit like the alchemy that transforms raw ingredients into a delectable dish This curing process is crucial; it’s a bit like the alchemy that transforms raw ingredients into a delectable dish frp boat body. The timing and temperature must be just right to ensure the resin hardens without cracking or warping the FRP structure.

frp boat body. The timing and temperature must be just right to ensure the resin hardens without cracking or warping the FRP structure.The choice between Pultruded Grating and Molded Grating will depend on specific application needs, budget, and the preferences of the manufacturer or end user.

We produce molded FRP grating in many practical standard dimensions, including 12”, 24”, 36”, and 48” widths in a variety of lengths that can be used as-is or cut down to your requirements.

Fiberglass Covered Grating:

For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations

For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations