...

2025-08-16 09:43

1641

...

2025-08-16 09:35

2260

...

2025-08-16 09:30

1404

...

2025-08-16 09:22

2332

...

2025-08-16 09:19

492

...

2025-08-16 09:15

1898

...

2025-08-16 09:03

1565

...

2025-08-16 08:28

2491

...

2025-08-16 08:04

1606

...

2025-08-16 07:30

363

- An impact drill bit is fundamentally different from a standard drill bit due to its ability to absorb and distribute the intense force generated by impact drivers. The primary advantage of these bits lies in their durability and resistance to wear, thanks to their robust construction. Most impact drill bits are made from premium materials like carbide or high-speed steel, ensuring they can endure the repetitive hammering action of an impact drill without breaking or bending.

- Another significant advantage of FRP tanks is their lightweight nature. Compared to traditional steel or concrete tanks, FRP tanks are significantly lighter, which reduces transportation costs and makes them easier to handle and install. This is particularly beneficial for remote or hard-to-reach locations where access is limited.

- Despite these advantages, fiberglass shells also present challenges. They can be brittle under certain conditions and may require skilled labor for installation. However, ongoing research and development in composite materials are continually addressing these issues, promising even more robust and user-friendly solutions in the future.

- Tap Drill Bit Sizes and Shapes

- In conclusion, high-quality drill bits are not mere tools but investments that pay dividends in time saved, quality achieved, and versatility enjoyed. As the cornerstone of many drilling tasks, their sophistication and resilience make them invaluable assets in the pursuit of precise, clean, and efficient drilling across a plethora of applications. Whether in heavy-duty industry settings or delicate artisan crafts, the right drill bit can transform any drilling challenge into an opportunity for excellence.

- Beyond their primary function, FGD scrubbers also contribute to the reduction of other pollutants like mercury and particulate matter. This multi-pollutant control capability makes them an essential component in modern pollution control strategies.

- FRP flanges, made from a combination of glass fibers and a polymer matrix, offer numerous advantages over traditional metal counterparts. Their lightweight nature significantly reduces installation time and labor costs, making them an attractive option for large-scale projects. They are also highly resistant to corrosion, a trait that renders them ideal for use in harsh environments such as chemical plants, oil refineries, and wastewater treatment facilities where exposure to corrosive substances is inevitable.

For further details on mesh openings and panel sizes, please view our Sizes & Options.

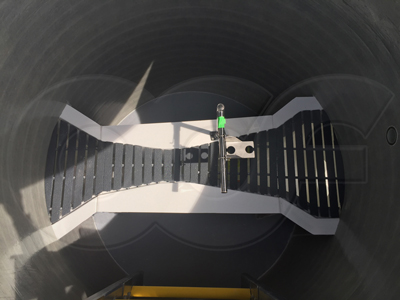

Molded Fiberglass Grating:

And in orchestral settings, the clear, well-defined pitch makes them suitable for use in smaller ensembles where each note must be heard distinctly And in orchestral settings, the clear, well-defined pitch makes them suitable for use in smaller ensembles where each note must be heard distinctly

And in orchestral settings, the clear, well-defined pitch makes them suitable for use in smaller ensembles where each note must be heard distinctly And in orchestral settings, the clear, well-defined pitch makes them suitable for use in smaller ensembles where each note must be heard distinctly fiberglass drum.

fiberglass drum.Common sheet sizes for FRP grating include: 4’x8′, 4’x12′, and 3’x10′. Common thicknesses include: 1″, 1.5″ and 2″

The Strength & Durability of FRP Grating