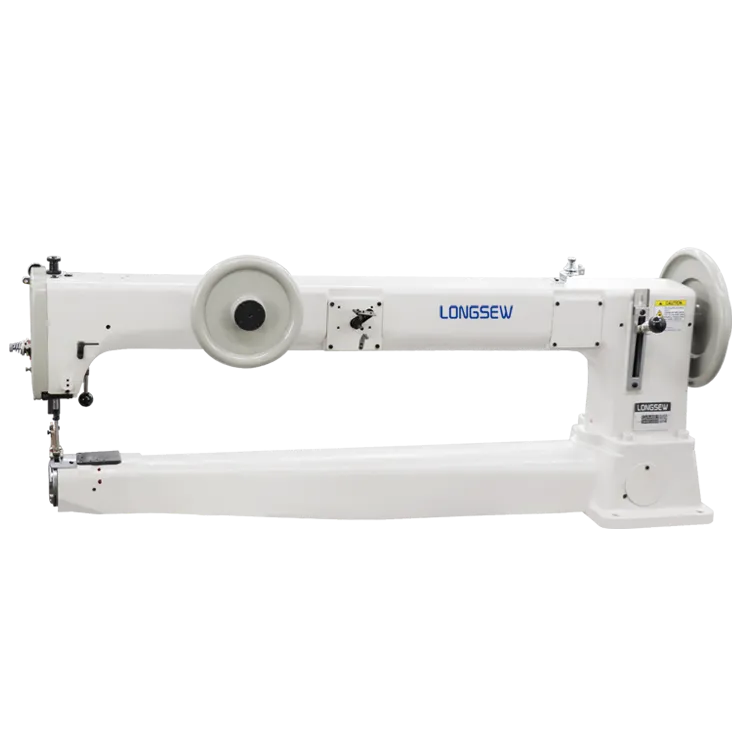

Why Choose a Manual Leather Sewing Machine?

Sewing machines are classified into different categories: electric, computerized, mechanical, overlock, and embroidery sewing machines. These machines have basic settings and ought to be used manually. Electronic sewing machines have motorized functions. The computerized machines can even be connected to the internet.

When considering a purchase, take into account the machine's features, the type of projects you intend to undertake, and your budget. Reading reviews and watching tutorial videos can also help you make a well-informed decision.

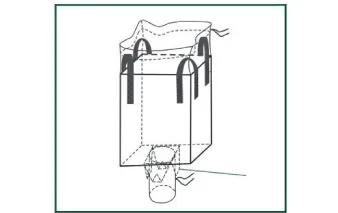

In the textile and packaging industries, the production of polypropylene (PP) bags has gained immense popularity due to their durability, versatility, and cost-effectiveness. With the increasing demand for these eco-friendly bags, the need for efficient and high-quality manufacturing processes has become paramount. One significant advancement in this field is the introduction of the PP bag silai machine, which has revolutionized how these bags are produced. This article explores the key features and benefits of PP bag silai machines, highlighting their importance in modern manufacturing.

A tote bag is an ideal beginner project that allows you to practice straight stitching while creating something useful. To make a simple tote bag, you’ll need two pieces of fabric, preferably canvas or cotton, cut into rectangles. Sew the sides together, leaving the top open for handles. You can also add pockets or embellishments to personalize your tote. This project can be completed in under an hour and is perfect for grocery runs or carrying books.