Drill pipes are essential for transmitting drilling fluids and rotational force from the surface to the drill bit. High-strength steel alloys are commonly used for drill pipes due to their ability to withstand high torque and pressure.

2. Telecommunications These rods serve as support structures for cables and antennas due to their non-conductive properties. They can be used to create stable frameworks for wiring while preventing electrical interference.

4. Durability and Weather Resistance Due to its construction from high-tensile steel, concertina wire is highly resistant to corrosion and wear. It can withstand extreme weather conditions, including rain, snow, and intense heat, thus ensuring longevity and reliability. This makes it a wise investment for outdoor applications that require a durable security solution.

Conclusion

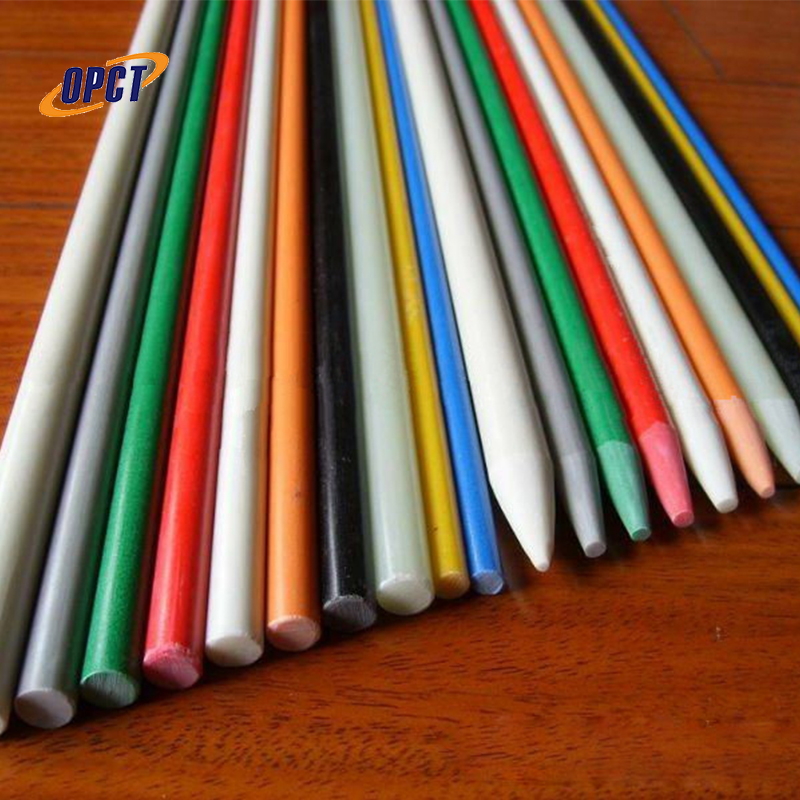

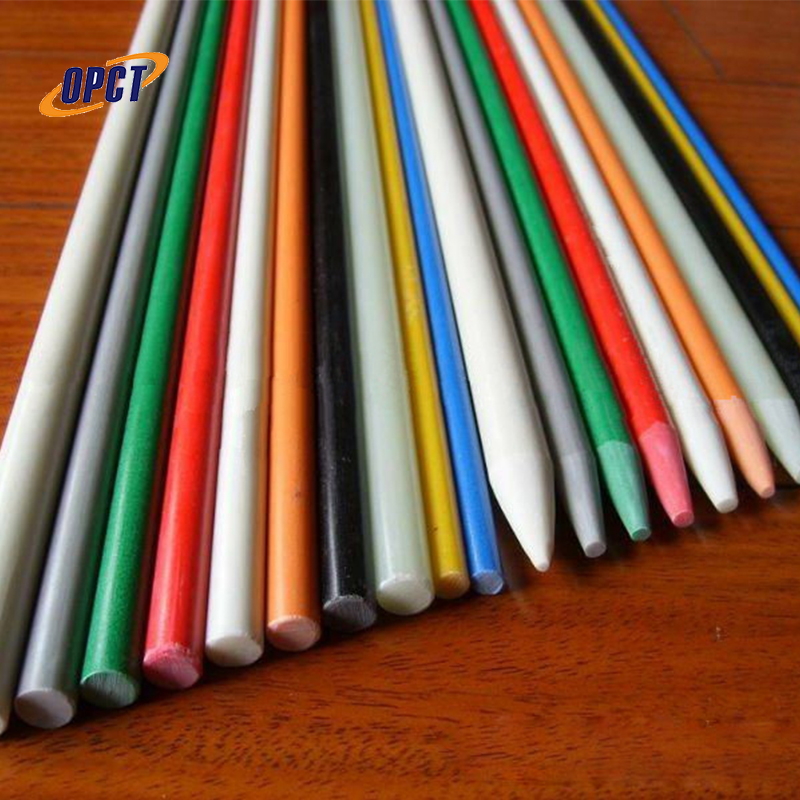

3% and 4% fiberglass rods find applications across multiple industries. In the construction industry, they are often used in the reinforcement of concrete structures, where their tension and compressive strengths are utilized to improve overall stability.

Their design allows for optimal heat transfer, ensuring that the cooling process is as efficient as possible Their design allows for optimal heat transfer, ensuring that the cooling process is as efficient as possible

Their design allows for optimal heat transfer, ensuring that the cooling process is as efficient as possible Their design allows for optimal heat transfer, ensuring that the cooling process is as efficient as possible fiberglass cooling tower manufacturers. This can result in cost savings for the industries that rely on these towers for their operations.

fiberglass cooling tower manufacturers. This can result in cost savings for the industries that rely on these towers for their operations.Chemical tank storage plays a crucial role in various industries, from pharmaceuticals and agriculture to food production and energy. These storage systems are vital for safely keeping liquid chemicals, ensuring that businesses can operate efficiently while minimizing risks to human health and the environment. In this article, we will explore the key aspects of chemical tank storage, including types of tanks, safety measures, regulatory requirements, and best practices.

electric iron without wire. By eliminating the need for a power cord, this iron reduces energy consumption and carbon emissions, helping to create a more sustainable living environment. This eco-friendly feature is a major selling point for many consumers who are looking to reduce their carbon footprint.

Moreover, China electro galvanized barbed wire is available in various sizes, gauges, and lengths, making it versatile and suitable for different applications. Whether it is used for securing residential properties, commercial buildings, agricultural lands, or government facilities, this type of barbed wire can be customized to meet specific requirements and provide the desired level of security.

In the world of construction and manufacturing, the importance of fasteners cannot be overstated. Among the plethora of fasteners available today, coiled nails have emerged as a game changer, offering efficiency and strength in various applications. This article delves into the rise of coiled nail factories and how they are shaping the fastener industry.

Moreover, in varying environmental conditions, the quality and length of concertina wire are essential for maintaining effectiveness. In areas prone to harsh weather, longer and sturdier rolls can create a more resilient barrier against elements like wind, rain, and snow. Similarly, when improperly maintained, shorter sections can sag or become damaged more easily, leading to security vulnerabilities.

China's position as a leading manufacturer of PVC coated steel wire ropes signifies the country's capacity for innovation and quality in the manufacturing sector. As industries continue to evolve and face new challenges, the demand for high-performance materials will only increase. By understanding the benefits and applications of PVC coated steel wire ropes, industry players can make informed decisions that enhance operational efficiency and safety. The future of these ropes, marked by technological advancements and sustainability, promises significant contributions to various sectors worldwide.

1. Strength and Durability One of the main benefits of using concrete cap nails is their exceptional strength. They can penetrate dense concrete and masonry materials without bending or breaking, providing a secure hold even in heavy-duty applications.

fiberglass septic tank installation. Additionally, fiberglass tanks are non-porous, which means that they do not absorb odors or allow leakage of harmful chemicals into the soil.

Durability is a hallmark of square wire mesh fencing. Generally constructed from high-quality steel, these fences are resistant to rust and corrosion, especially when galvanized. This makes them suitable for long-term outdoor use, even in harsh weather conditions. Furthermore, they require minimal maintenance, as occasional inspections for wear and proper tightening of knots or connections are typically all that’s needed to retain their structural integrity.

square wire mesh fence

In the agricultural sector, this mesh is often employed in fencing and animal enclosures. It provides a robust barrier that can withstand the elements and the pressure from animals, helping to keep livestock safe while allowing for proper ventilation and visibility.

Reliability in Supply Chain

However, while the benefits of flat razor wire are compelling, it is essential to consider the legal and ethical implications of its use. Proper installation and compliance with local laws and regulations are crucial to avoid potential liabilities. Property owners should also inform surrounding communities about their security measures to promote awareness and prevent misunderstandings.

For businesses seeking to source copper square boat nails, it is crucial to stay informed about market trends and pricing dynamics. By understanding the influence of raw material costs, manufacturing efficiencies, and market competition, companies can make informed decisions that align with their operational needs and budget constraints.

OEM roofing nails are specifically designed and manufactured to meet the stringent requirements set by roofing material producers. These nails are tailored to function seamlessly with various types of roofing systems, including asphalt shingles, metal roofing, and tiles. The specifications of OEM roofing nails ensure they can handle the environmental stressors such as wind, rain, and extreme temperatures, which are crucial for maintaining the structural integrity of a roof.

china concrete steel nail. This makes them ideal for use in a wide range of projects, from building foundations to hanging pictures on walls.

Types of Wire Mesh

In conclusion, FRP winding equipment represents a significant advancement in composite manufacturing. Its ability to produce high-quality FRP products efficiently makes it an invaluable asset in today's manufacturing environment. As industries continue to explore innovative applications for composite materials, the importance of advanced FRP winding technology will undoubtedly grow, paving the way for enhanced performance and sustainability across various sectors.

Understanding Black Steel Nails

The trend toward sustainability is also influencing developments in pultrusion machinery. As industries increasingly demand eco-friendly solutions, manufacturers are designing machines that utilize bio-based resins and recyclable fibers. This shift not only reduces environmental impact but also opens new market opportunities for manufacturers catering to eco-conscious consumers.

Once the glass is melted, it needs to be transformed into fibers. This transformation typically takes place in a fiberizing chamber, where the molten glass is drawn through fine orifices to create continuous filaments. The innovation of using advanced fiberization techniques has resulted in higher production rates and improved fiber properties. For instance, the introduction of high-speed spinning technologies has increased production efficiency while minimizing waste material.

fiberglass production line

The Versatility of 1% Fiberglass Tubes

Understanding Fiberglass

Conclusion