down the hole drilling machine

Implementing robust safety protocols and contingency plans can help manage risks associated with downhole drilling. This includes preparing for potential blowouts, managing gas levels, and responding to unexpected geological conditions. The integration of real-time monitoring systems can further enhance safety by providing alerts and data on potential hazards.

1. Regular Inspections Frequent checks for signs of wear, cracks, or deformation can help identify issues early on. Monitoring the condition of jaw plates allows for timely replacements before significant damage occurs.

The pile driver should pay attention to the following points during the piling process to avoid accidents:

Problem: The pump does not produce water, and the vacuum gauge indicates a high vacuum

Problem: The pump does not produce water, and the vacuum gauge indicates a high vacuum

Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings

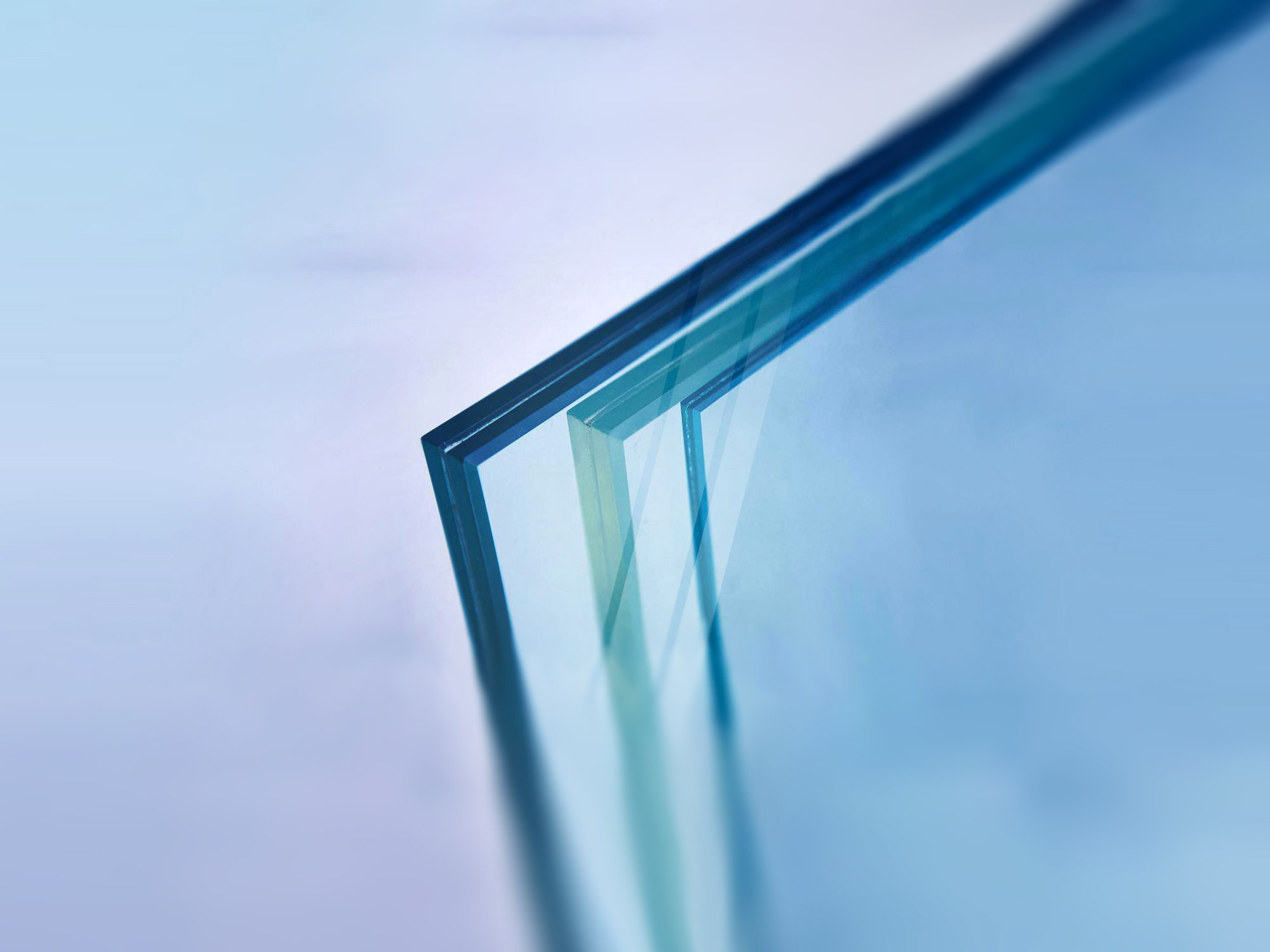

Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings . Their surfaces, at once opaque and transparent, challenge our perception of space and volume. These buildings not only house functions but also invigorate urban landscapes with their dynamic interaction with the surroundings.

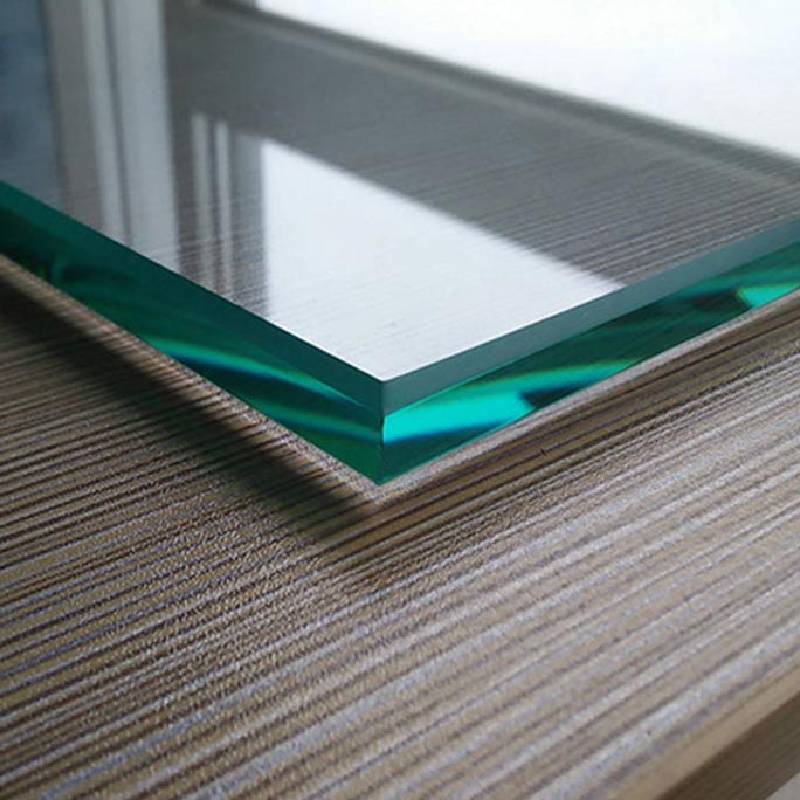

. Their surfaces, at once opaque and transparent, challenge our perception of space and volume. These buildings not only house functions but also invigorate urban landscapes with their dynamic interaction with the surroundings. This safety feature makes it an indispensable component in architectural designs, particularly for windows, doors, shower enclosures, and even in vehicle manufacturing This safety feature makes it an indispensable component in architectural designs, particularly for windows, doors, shower enclosures, and even in vehicle manufacturing

This safety feature makes it an indispensable component in architectural designs, particularly for windows, doors, shower enclosures, and even in vehicle manufacturing This safety feature makes it an indispensable component in architectural designs, particularly for windows, doors, shower enclosures, and even in vehicle manufacturing