- WG1223546

Update: Leakage-free

Passenger carsOil seals normally consist of three basic components: the sealing element, the metal case, and garter spring.

- Offers a high degree of strength

Choose a seal that has the appropriate dimension needed for your application. The seal should properly fit the space between the stationary and rotating parts.

Fluorosilicone

- * Fluorocarbon rubber Known for its extreme chemical resistance and high temperature tolerance, fluorocarbon rubber is used in applications that require the highest level of protection against chemicals and extreme temperatures.

- Benefits of Using Lip Seal Gaskets

- A gasket's effectiveness lies in its ability to conform to irregularities on the mating surfaces, creating a reliable barrier against fluids, gases, or environmental elements. In the case of square rubber gaskets, their geometric shape provides even pressure distribution, optimizing the seal and enhancing durability. The 'square' design is particularly advantageous in applications where precise fitting and uniform compression are critical.

Over Remove most of the fixings, then support the sump with one hand while you take out the last few.

- Spark plug wires are a critical component in the ignition system of your car. They transmit the high voltage electrical current from the ignition coil to the spark plugs, which then ignite the air-fuel mixture in the combustion chamber. Over time, these wires can become worn or damaged, leading to poor engine performance and potentially even engine damage. Therefore, it is essential to test your spark plug wires regularly to ensure they are in good condition.

High carbon steel wire

(JIS* SWB)- Valve cover gasket bolts come in various sizes and grades, each designed to withstand the specific torque requirements of different engines. They are usually made from high-strength steel or alloy, capable of withstanding the intense heat and pressure within the engine compartment. The correct tightening sequence and torque specification are essential to ensure these bolts don't loosen over time, causing leaks or even damaging the threads in the cylinder head.

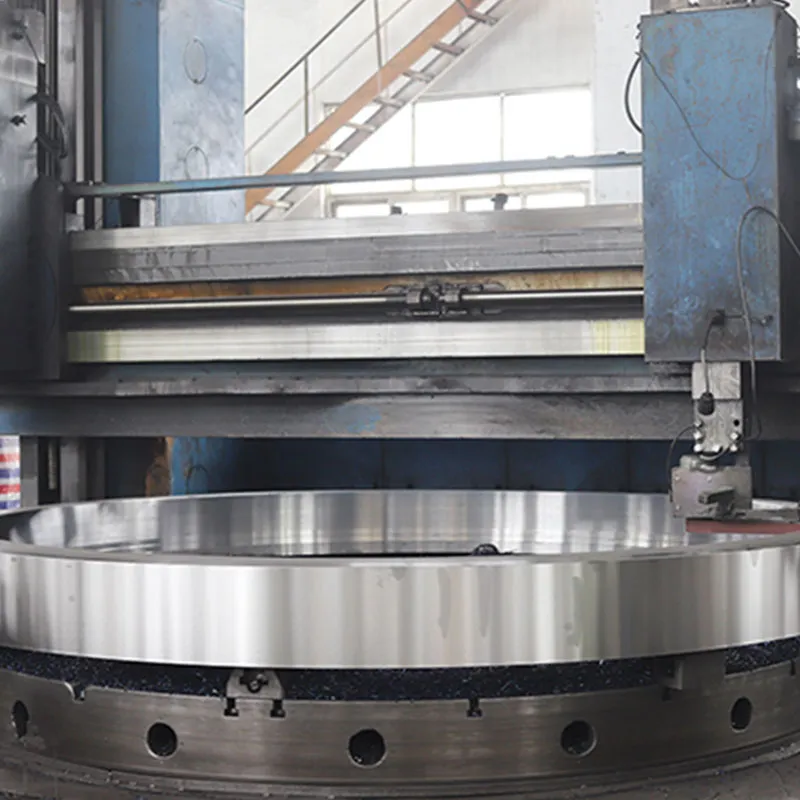

Shaft seals, dirt seals, grease seals, lip seals, and many other names are only a few of the many names given to oil seals. They are simple components used in rotary shaft machinery to keep oil from leaking and impurities like dust, dirt, and water out. However, an oil seal’s most crucial role is to safeguard all ball, sleeve, and roller bearing types found in rotating shafts. Additionally, the seals stop blending two fluids that shouldn’t mix, such as water and oil.

Pressure

Sign in to download full-size image- One of the key benefits of rotary shaft oil seals is their ability to prolong the lifespan of equipment and machinery by preventing the entry of harmful particles and contaminants. This helps reduce maintenance costs and downtime, ultimately improving overall efficiency and performance.

Propylene (fluorinated ethylene)

Auto Gasket: Essential Sealing Components in Vehicles

- 5. Replace the spark plug wires and ensure that they are properly connected to the distributor.

- 1. Automotive industry NBR oil seals are used in engine seals, transmission seals, differential seals, and power steering seals.

Detergents: This additive isn’t like your laundry detergent! It focuses on preventing deposits, rust, and corrosion from forming on the piston ring area, piston under-crown, and other surfaces that tend to overheat.

BS

These oil seals are created from a low-temperature tolerant compound. Benefits include:

- Moreover, silicone oil seals exhibit excellent resistance to ozone, weathering, and aging, which significantly extends their service life. They are also resistant to a variety of chemicals, making them suitable for use in harsh chemical environments. In the medical and food industries, where hygiene is paramount, silicone oil seals are preferred due to their non-toxicity and ease of cleaning.

- The design of oil seals is also crucial to their performance. Factors such as the seal's geometry, material selection, and the use of additional components like springs or backup rings can significantly impact its ability to contain oil and prevent leaks. Engineers must carefully consider these factors when designing oil seals to ensure they meet the rigorous demands of industrial machinery.

Encapsulate inorganic acid, have chemical substances; In the military industry, fluorine rubber is mainly used