...

2025-08-15 08:36

2941

...

2025-08-15 08:26

922

...

2025-08-15 08:15

397

...

2025-08-15 07:21

2771

...

2025-08-15 07:15

387

...

2025-08-15 07:14

2396

...

2025-08-15 07:07

1449

...

2025-08-15 07:00

2772

...

2025-08-15 07:00

2748

...

2025-08-15 06:52

1214

Nanoparticles

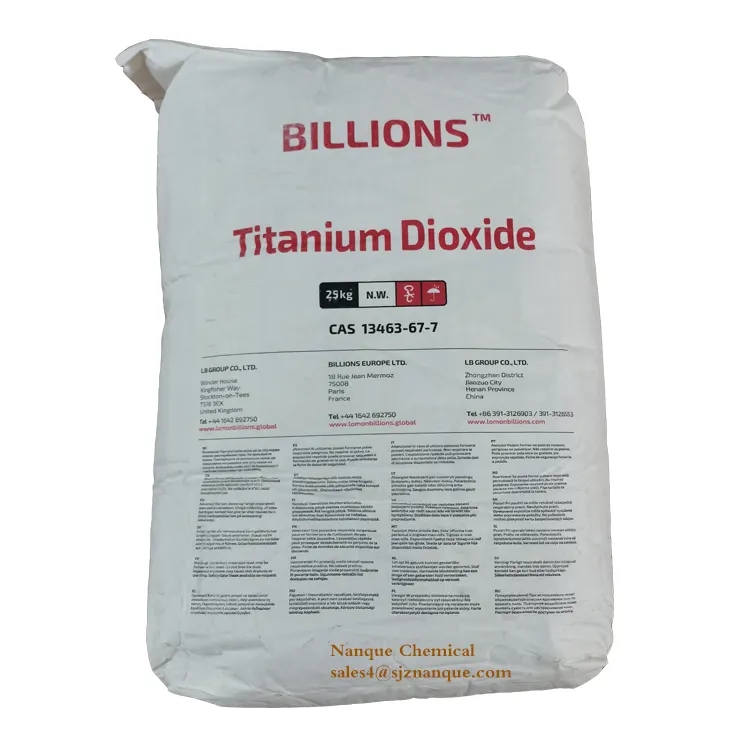

- Titanium dioxide, commonly known as TiO2, is a naturally occurring oxide of titanium. Among its two primary crystal forms, rutile TiO2 is particularly valued for its high refractive index and exceptional hiding power, making it an essential component in the production of emulsion latex paints. The unique properties of rutile titanium dioxide enhance the quality and performance of latex paints, establishing its manufacturer's reputation for producing top-tier products.

Genotoxicity refers to the ability of a chemical substance to damage DNA , the genetic material of cells. As genotoxicity may lead to carcinogenic effects, it is essential to assess the potential genotoxic effect of a substance to conclude on its safety.

Lithopone 30% CAS No. 1345-05-7 / Production Method

These companies have established reputations for producing high-quality titanium dioxide powder that meets stringent quality standards These companies have established reputations for producing high-quality titanium dioxide powder that meets stringent quality standards

These companies have established reputations for producing high-quality titanium dioxide powder that meets stringent quality standards These companies have established reputations for producing high-quality titanium dioxide powder that meets stringent quality standards