Mining Industry

Mining Industry

The durability and effectiveness of jaw plates significantly impact the overall performance of the jaw crusher. When materials are fed into the crusher, they are subjected to immense pressure as the movable jaw compresses them against the stationary jaw. The shape, design, and material composition of the jaw plates are critical in determining the crushing efficiency. High-quality jaw plates contribute to the longevity of the crusher, ensuring consistent performance over time.

Conclusion

The innovation behind the ZJ slurry pump lies in its hydraulic design. It is engineered to achieve high efficiency in the transfer of slurries, reducing both energy consumption and operational costs. Available in different sizes and designs, the ZJ pump can be tailored to meet the specific demands of various applications, including dredging, tailings management, and waste handling.

At its core, submarine hammer drilling employs a powerful hammer mechanism to drive a drill bit into the seabed. The system utilizes both air and water pressure to deliver repeated impacts on the drill bit, which enables it to break through hard rock formations or sediments that might hinder installation efforts for marine infrastructure. The design of the hammer ensures that the energy is efficiently transmitted to the drill bit, allowing it to operate at significant depths.

Inspection Before Using the Integrated Drilling and Piling Machine:

5. Improved Penetration Rates DTH rigs deliver higher penetration rates, allowing projects to progress more quickly. The utilization of air-powered hammers means fewer interruptions compared to other drilling techniques, which rely on continual drilling fluid supply.

- Construction For foundations, pilings, and site preparation, DTH techniques enable precise hole placement and stability in challenging geological conditions.

The Future of Drilling in Mining

In summary, taper roller bearings are used in a diverse range of applications across various industries, where their ability to support radial and axial loads, provide high load-carrying capacity, and withstand demanding conditions is essential.

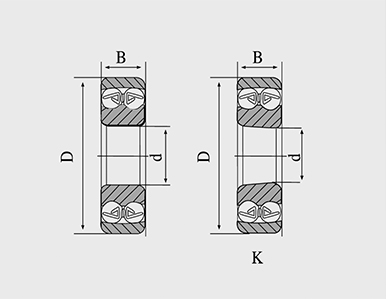

- Spherical Roller Bearings: Spherical roller bearings are specifically designed to accommodate misalignment and shaft deflection, making them suitable for applications where alignment issues are common or where the bearing may be subjected to dynamic or oscillating loads.

6904z bearing dimensions. Typically, bearings in the 6900 series adhere to standard tolerances, ensuring consistent performance across different operating conditions. Made from high-quality steel, the 6904Z offers excellent wear resistance and durability.

6904z bearing dimensions. Typically, bearings in the 6900 series adhere to standard tolerances, ensuring consistent performance across different operating conditions. Made from high-quality steel, the 6904Z offers excellent wear resistance and durability.In summary, spherical roller bearings are employed in diverse applications across various industries, where their ability to support heavy radial and axial loads, accommodate misalignment, and withstand harsh operating conditions is essential for reliable and efficient machinery performance.

For example, in automotive engines, these bearings help to reduce friction and heat generation, leading to improved fuel efficiency and reduced emissions For example, in automotive engines, these bearings help to reduce friction and heat generation, leading to improved fuel efficiency and reduced emissions

For example, in automotive engines, these bearings help to reduce friction and heat generation, leading to improved fuel efficiency and reduced emissions For example, in automotive engines, these bearings help to reduce friction and heat generation, leading to improved fuel efficiency and reduced emissions 6002 ball bearing.

6002 ball bearing. nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments.

nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments. lm67010 bearing. This means that it requires less energy to rotate, resulting in increased efficiency and reduced wear on the bearing itself. This is especially beneficial in applications where energy consumption is a critical factor, such as in wind turbines or other renewable energy systems.

lm67010 bearing. This means that it requires less energy to rotate, resulting in increased efficiency and reduced wear on the bearing itself. This is especially beneficial in applications where energy consumption is a critical factor, such as in wind turbines or other renewable energy systems.

deep groove ball bearing contact angle. Due to the symmetrical shape of the bearing, it can automatically adjust to misalignment caused by installation errors or thermal expansion. This self-aligning feature helps to reduce wear and tear and extends the bearing's service life.

deep groove ball bearing contact angle. Due to the symmetrical shape of the bearing, it can automatically adjust to misalignment caused by installation errors or thermal expansion. This self-aligning feature helps to reduce wear and tear and extends the bearing's service life.