- In most jurisdictions, emergency exit floor markings are typically bright green, contrasting starkly against the floor's surface to ensure high visibility even in low light conditions. The arrows on these markings point towards the direction of the exit, guiding people swiftly and efficiently. They are strategically placed along the shortest and safest path to the exit, avoiding potential hazards like stairs, sharp turns, or obstructed areas.

- In conclusion, fireproof adhesive tape is more than just a simple adhesive solution; it is a proactive measure against potential disasters. Its ability to provide instant protection, coupled with its ease of application, makes it an indispensable tool in today's safety-conscious world. As technology continues to advance, we can expect even more advanced forms of fireproof adhesive tape, offering increased efficiency and reliability in safeguarding lives and property against the destructive force of fire.

1. Plumbing Repairs One of the most common uses of Black Flex Tape is for emergency plumbing fixes. It can be used to seal leaks in pipes, hoses, and faucets quickly, preventing water damage and costly repairs. Whether you’re dealing with a small drip or a larger stream of water, this tape can provide an immediate solution.

- These markings are typically made of durable materials that can withstand high foot traffic and are strategically placed along floors to lead occupants to the nearest exit. They are often accompanied by symbols or arrows to further indicate the direction of the exit.

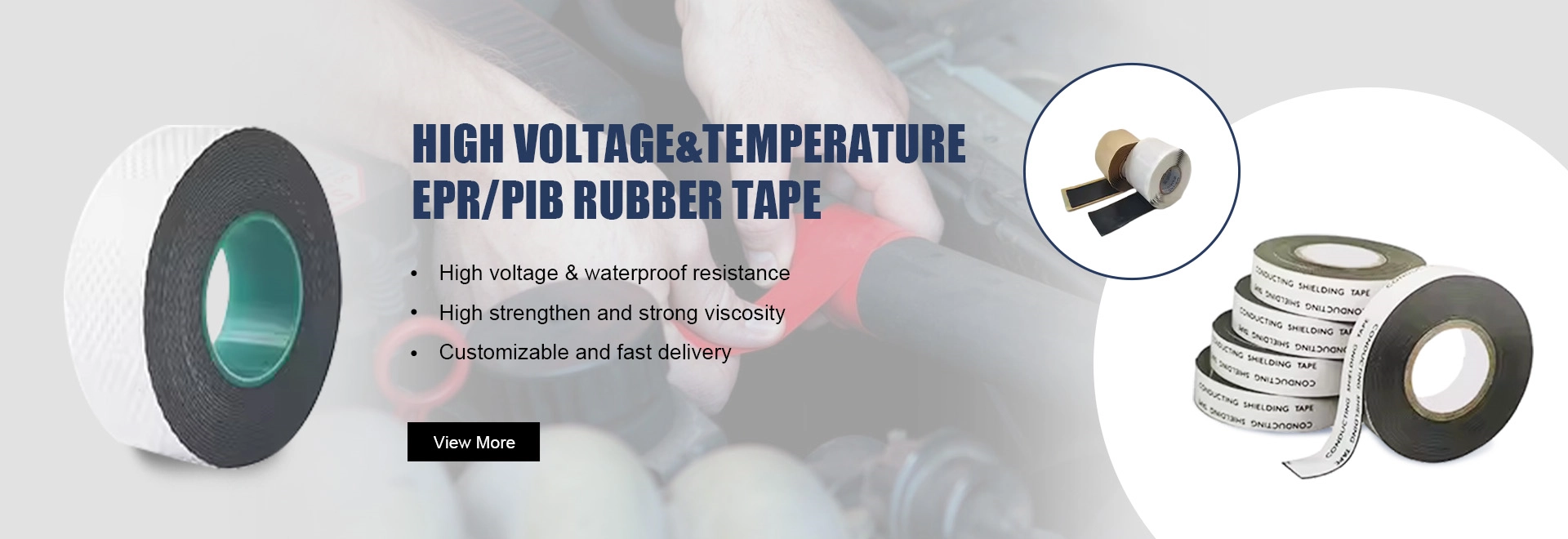

Characteristics of High Voltage Insulation Tape

Measure and Cut: Cut the desired length of silicone tape. Make sure it's slightly longer than the area you need to cover.

J50 High-voltage EPR Rubber Tape

Natural Rubber Based Adhesives

Rubber tape edge sealant: application, advantages and disadvantages

fireproof sealing strip. It is also crucial to choose the right type and size of the seal for each application to maximize its sealing capabilities.

In this article, we will explore the question: is electrical tape heat resistant?

floor marking yellow tape. Its bright color grabs attention, making it an effective visual tool in various environments. It not only enhances workplace safety but also promotes order and efficiency, demonstrating the power of color-coded communication in our daily lives.

floor marking yellow tape. Its bright color grabs attention, making it an effective visual tool in various environments. It not only enhances workplace safety but also promotes order and efficiency, demonstrating the power of color-coded communication in our daily lives.The first commercial tape for electrical insulation was cotton friction tape, which became available in the early 1930s. Vinyl electrical tape was introduced in the mid 40s. This advanced material provided dramatic advantages over friction tape, including improved adhesion and moisture protection. Vinyl tapes have been refined substantially over the years, and other tape products have been added as well. Today's tapes offer long-term performance, excellent adhesion, and temperature resistance — not to mention smooth unwind from the roll. Resistance to adhesive transfer, superior conformability, high tensile strength, good elastic memory and recovery, and wider installation and operational temperature ranges characterize premium products.

In summary, heat tape is a versatile and invaluable tool across multiple sectors. Its ability to provide precise, reliable heat makes it essential for preventing frost damage in pipes, crops, and buildings. As field technology advances, the efficiency and performance of heat tape continue to improve, cementing its role as a go-to solution for temperature management. Whether used in residential settings or industrial applications, understanding how to properly use and install heat tape can lead to significant benefits and peace of mind during cold weather conditions. With proper care and consideration, heat tape remains an investment in safety and efficiency.