Adhesives are a sadly overlooked aspect of tape selection. When you're purchasing tape for your business, it's easy to think about things like the material and the number of rolls. But too often, people don't consider the importance of the tape's adhesion. Different varieties of tape use different types of adhesive with different properties. If you don't factor in the adhesive type when you choose your tape, you might end up with an adhesive that's too weak or too strong for your projects. Too weak, and the tape will come loose. Too strong, and the tape might rip off paint or damage cardboard.

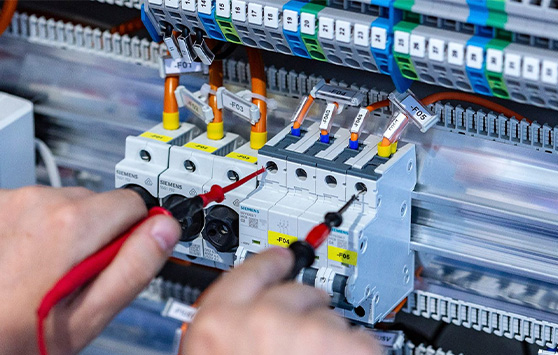

If you’re working with live wires, for example, it’s always best to err on the side of caution and use heat-resistant tape instead.

Beyond that point, the adhesive will begin to break down and the tape will no longer adhere properly.

flame proof tape. In vehicles, there are many components that generate heat and can potentially ignite a fire. By using flame proof tape to protect these components, manufacturers can reduce the risk of fires occurring in vehicles and improve overall safety.

Despite its many benefits, Flex Tape is not without its limitations. While it can be used to fix a wide range of issues, it is not a permanent solution and may need to be replaced periodically. It is also not recommended for use on flexible materials or surfaces that constantly move or bend, as it may not adhere properly.

Moreover, it finds application in the automotive industry for sealing car trunks, windows, and other areas prone to water intrusion Moreover, it finds application in the automotive industry for sealing car trunks, windows, and other areas prone to water intrusion

Moreover, it finds application in the automotive industry for sealing car trunks, windows, and other areas prone to water intrusion Moreover, it finds application in the automotive industry for sealing car trunks, windows, and other areas prone to water intrusion