- The power steering oil seal is a vital component in the power steering system of modern vehicles. It plays a crucial role in maintaining the proper functioning of the system by preventing leaks and ensuring that the power steering fluid remains within the system. In this article, we will discuss the importance of the power steering oil seal and how it contributes to the smooth and efficient operation of your vehicle.

Purpose of an Oil Seal

- 2. Install Correctly Ensure that the 14x22x5 oil seal is installed correctly and securely to prevent misalignment or damage during operation.

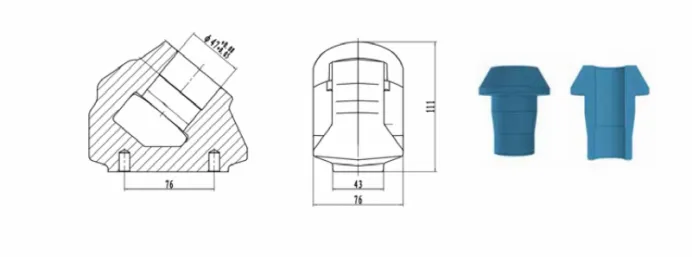

Figure 7: Oil seals for steel production equipment (rolling mill)

It is critically important that you choose the appropriate seal for an application. The seals should be ordered from a manufacturer of high repute. To get the best seals, it is important to give accurate design specifications. We describe the difference between mechanical seal and oil seal here.

The edge of the metal is finely ground after seal manufacture in a centerless grinder to enable an interference fit in the oil seal housing. A slight chamfer on the outer diameter (OD) of the seal is desirable for easy assembly. The sealing lip is prepared by buffing, grinding or cutting away the rubber flash which occurs at the sealing edge. A fine sealing edge creates sufficient pressure on the shaft to minimise spring load, leading to lower friction whilst maintaining effective seal performance. The garter spring plays an important role in the efficiency of the oil seal. If its tension is too high, heat will be generated between the sealing lip and the shaft, and result in rapid wear of the lip. If too low, the spring will be ineffective and the sealing lip will be worn away leading to leakage of the fluid.

If you are looking for the highest temperature resistant oil seals, Perfluoelastomer can go up to 600°F. If you are more concerned for low temperature, Chloroprene can go all the way down to 40°F, which is why it is used most commonly for refrigeration. And if FDA applications or medical devices are your primary concern, Butyl , the all petroleum compound, will be your best choice. As you can see, when choosing the right material to work with, you must analyze several other key components to help choose the right one.

Despite being a great substitute for more expensive high temperature resistant materials, polyacrylate has a problem of poor water compatibility and cold flexibility.

Auto oil seal Features