dth hammer manufacturers

FAQs

FAQs

Fuel efficiency has also improved significantly in modern models, reducing operational costs and minimizing environmental impact. Many manufacturers have focused on engineering compressors that maximize output while consuming less fuel, striking a balance between performance and sustainability.

FAQs

One of the standout features of 185% compressors is their robust pressure output. They usually provide air pressure ranges from 100 to 125 psi, suitable for driving pneumatic tools such as jackhammers, nail guns, and sanders. Additionally, many models offer adjustable pressure settings, allowing operators to customize the flow of air according to specific requirements.

Drilling equipment is essential in various sectors, including oil and gas, mining, construction, and environmental research. Each sector requires specialized machinery capable of performing specific tasks effectively. For instance, in the oil and gas industry, rotary drill rigs and downhole drilling tools are critical for accessing subterranean resources. In contrast, the mining sector demands heavy-duty equipment designed to penetrate solid rock and extract valuable minerals.

La innovación en los materiales y procesos de fabricación también ha impactado en el desarrollo de chocks para laminadores. Hoy en día, se utilizan aleaciones de alta resistencia y tecnologías avanzadas de fabricación para producir chocks más duraderos y eficientes. Esto no solo mejora la vida útil de los chocks, sino que también contribuye a la sostenibilidad de los procesos industriales al reducir la necesidad de reemplazos frecuentes.

Conclusion

6. Bearings

Conclusion

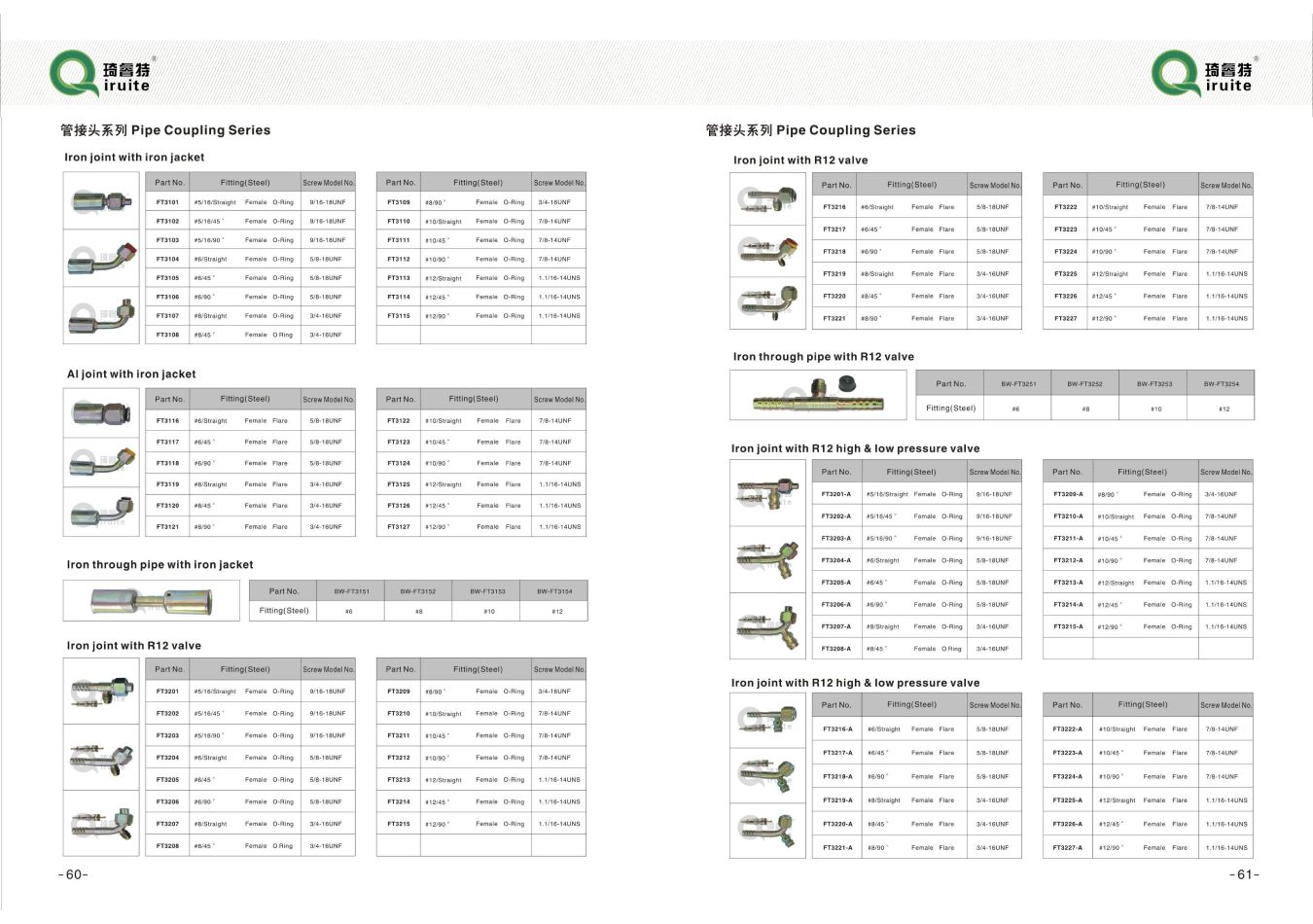

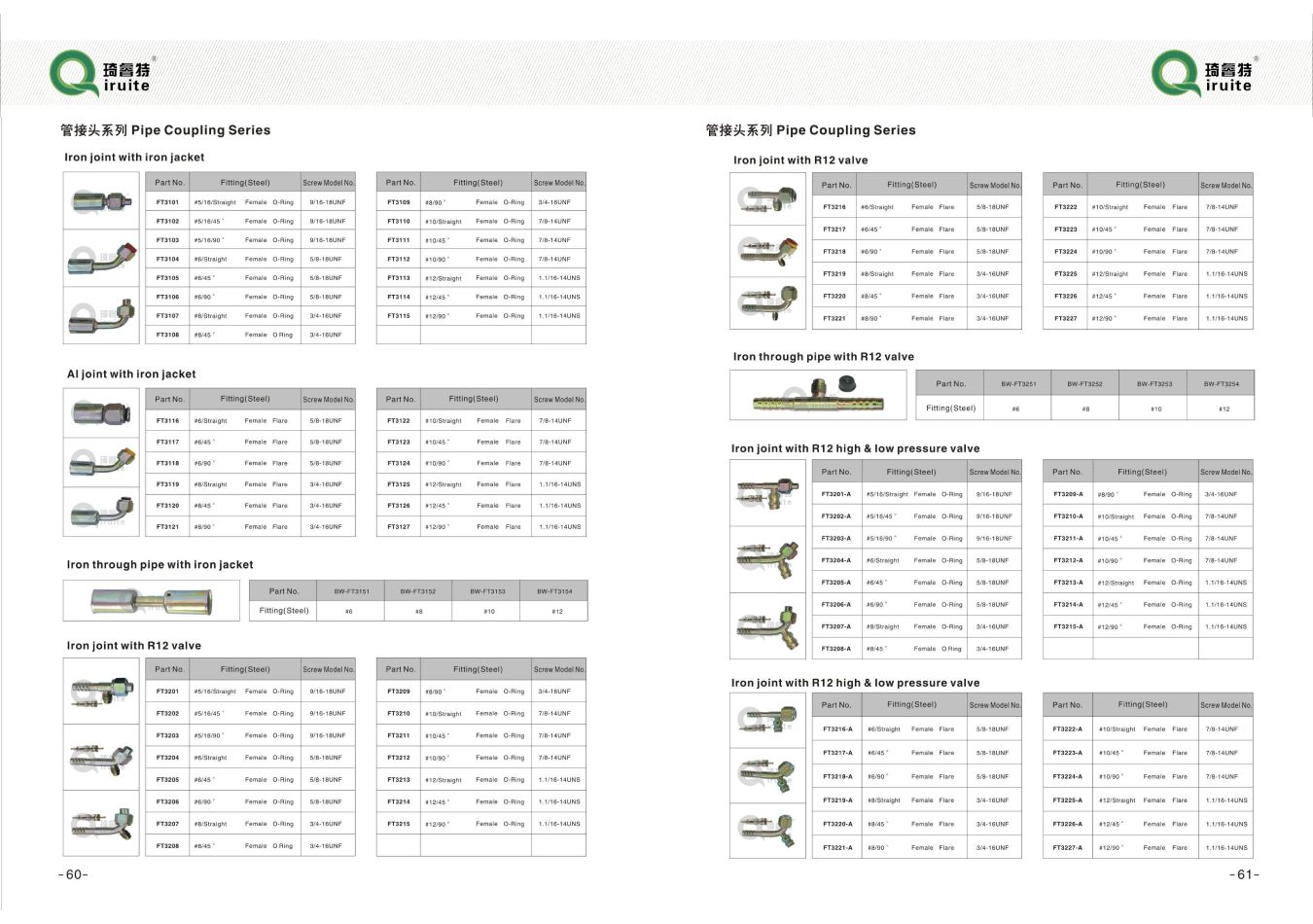

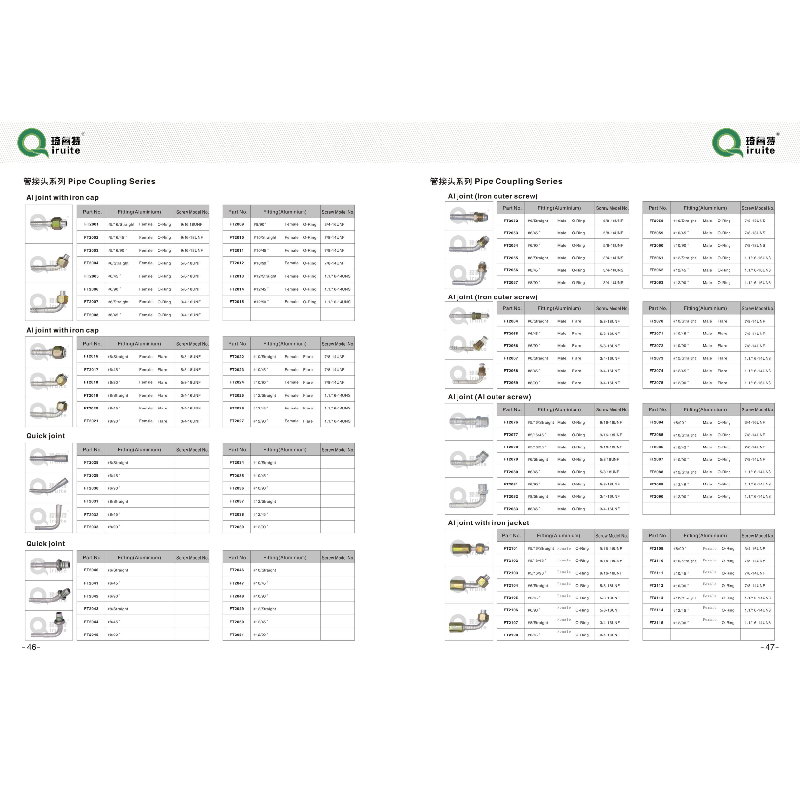

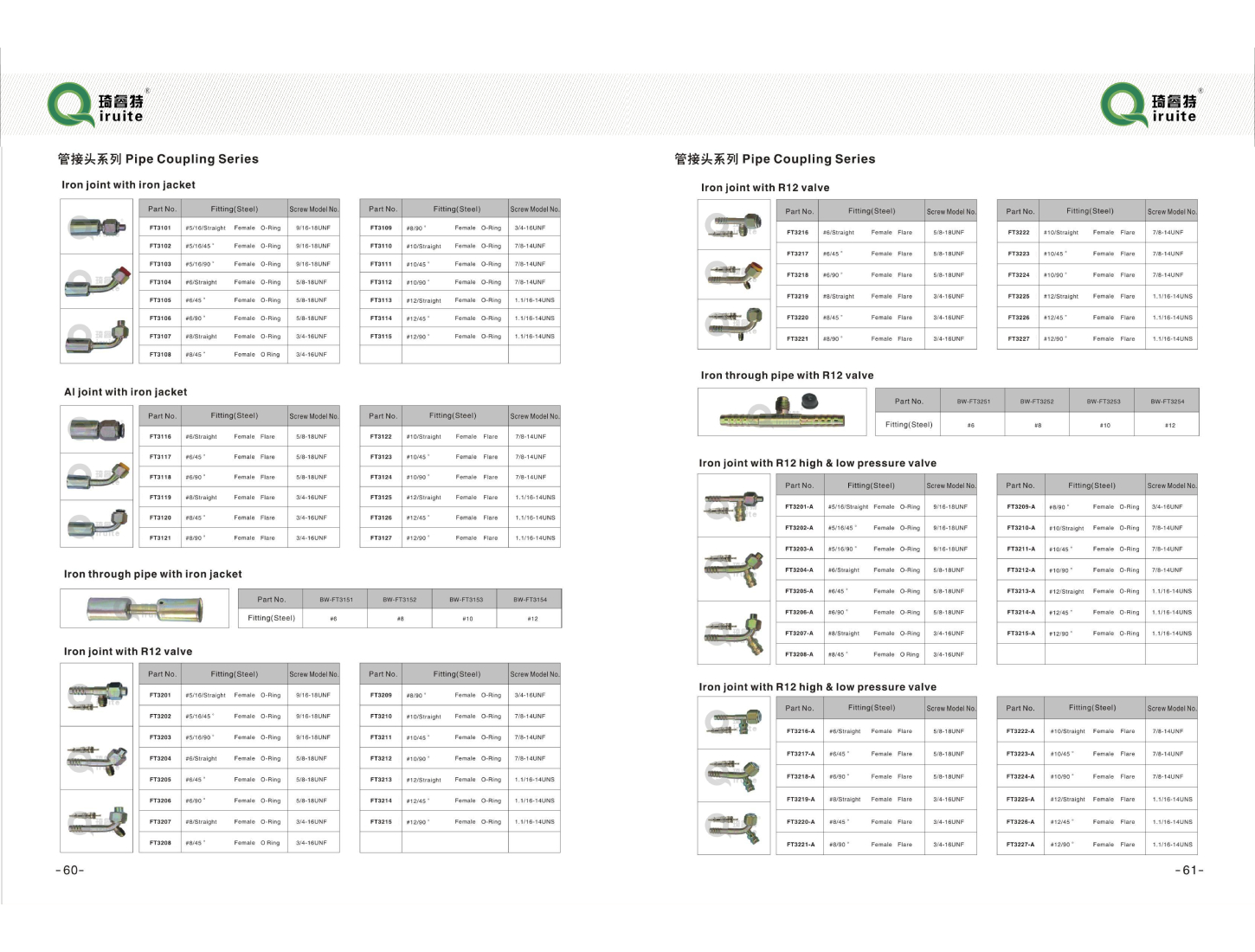

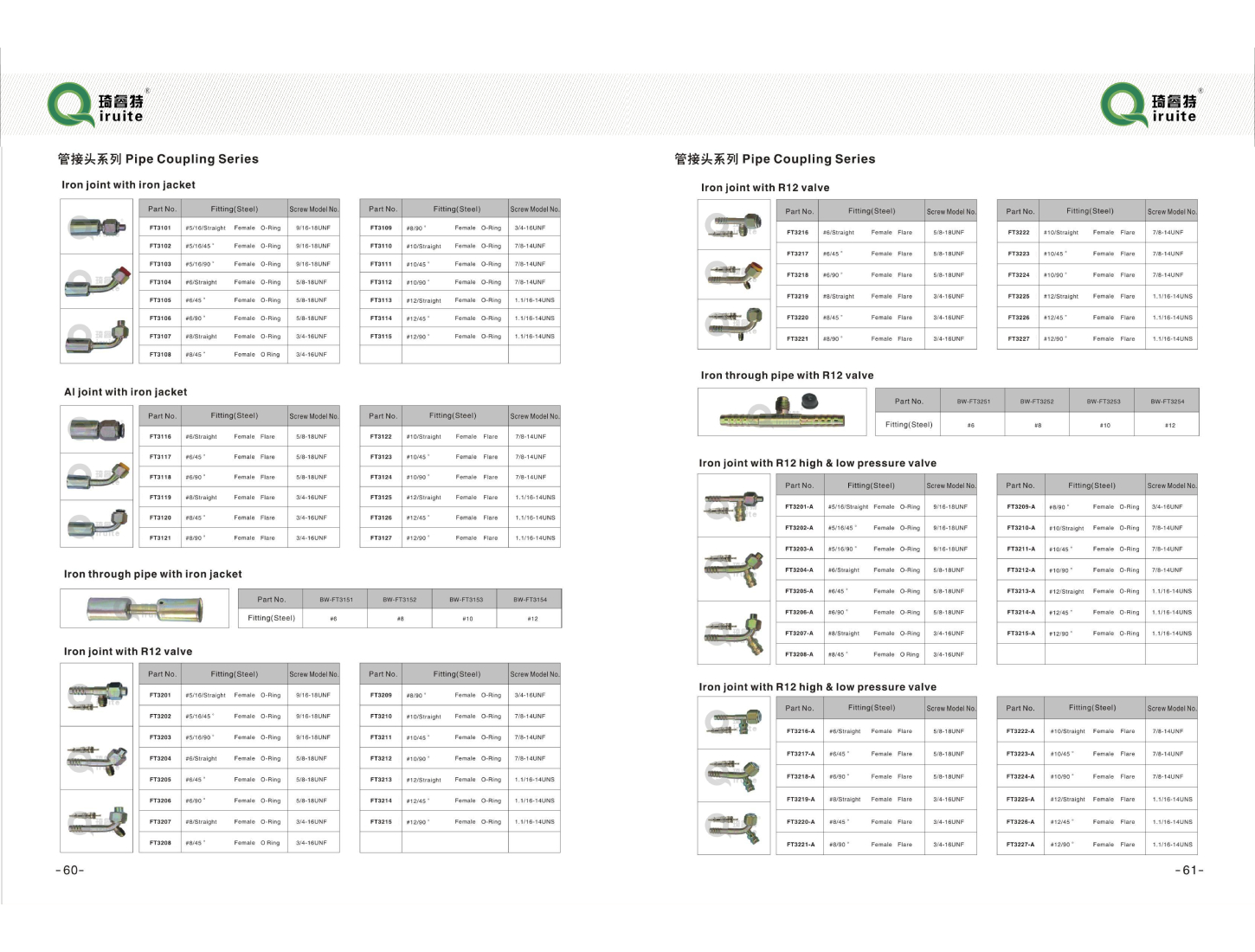

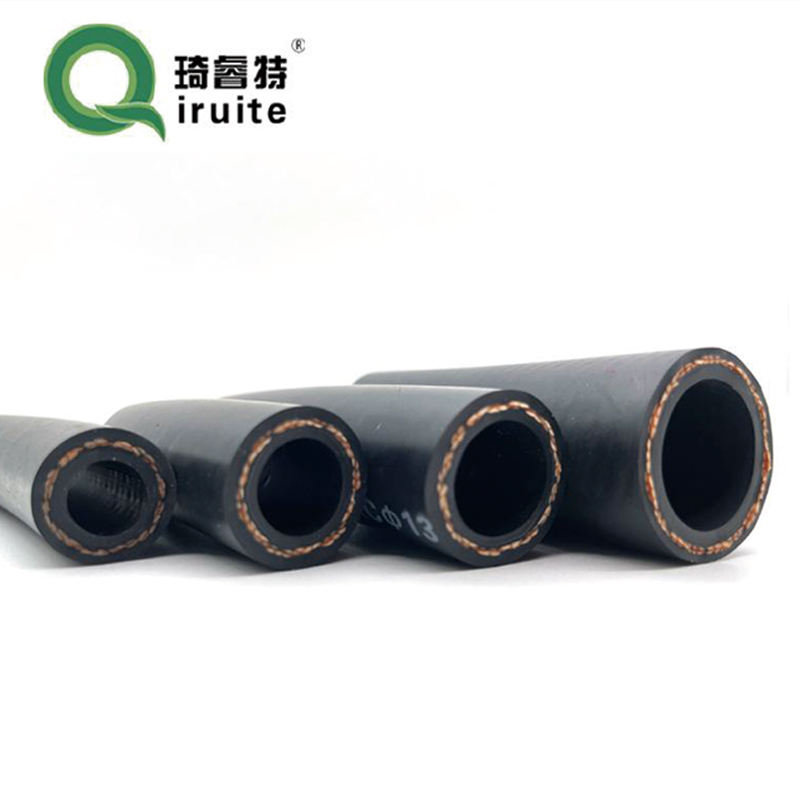

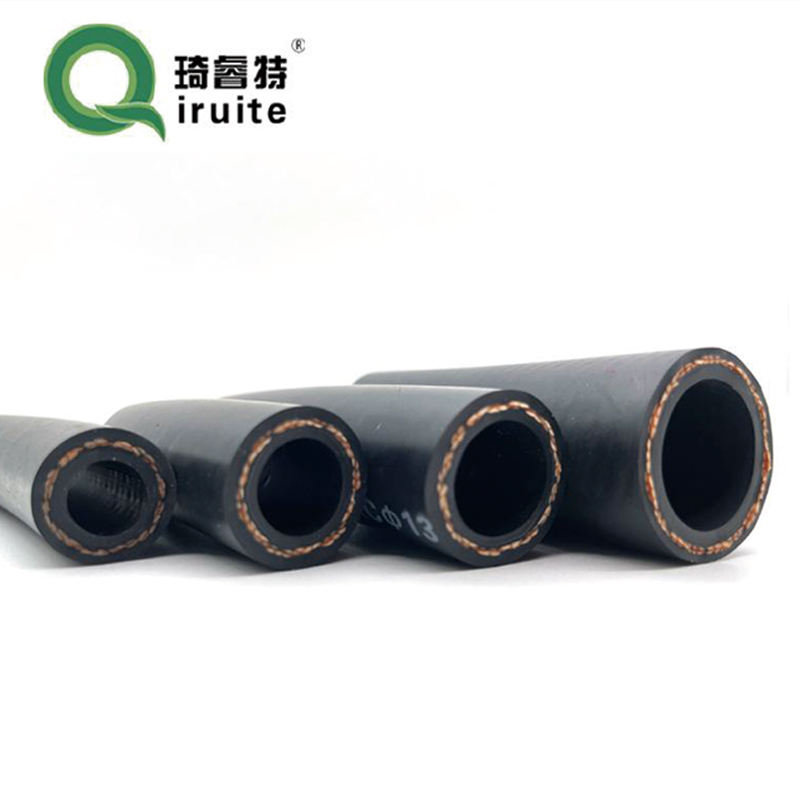

Both ac hose are compatible with most common refrigerants including R12 and R134a.

Please note, if you are sure the hose size, it is better to check again with professional technicians.

In February, 2016, Qiruiyte donates 30,000 RMB to the project of Water Supply Pipeline Network Renovation;

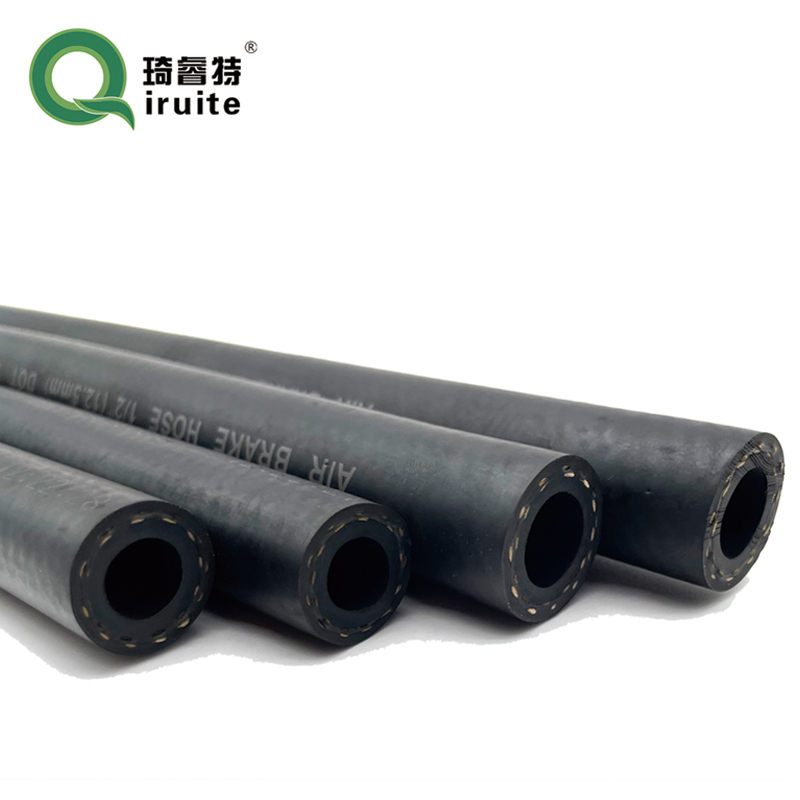

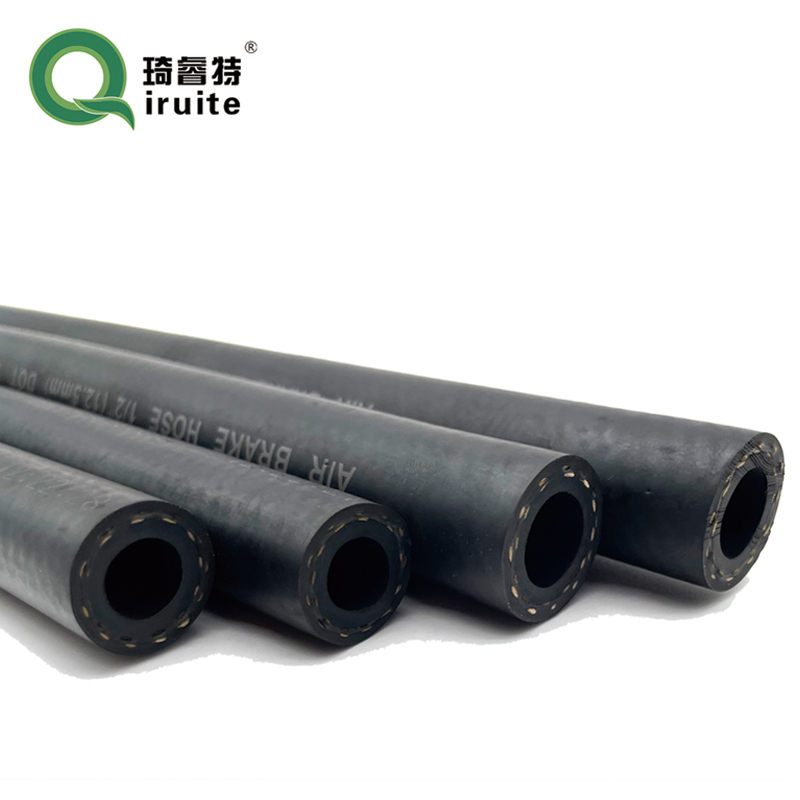

The hose should not come into contact with moving parts or hot surfaces to prevent damage and potential leaks The hose should not come into contact with moving parts or hot surfaces to prevent damage and potential leaks

The hose should not come into contact with moving parts or hot surfaces to prevent damage and potential leaks The hose should not come into contact with moving parts or hot surfaces to prevent damage and potential leaks 69 camaro power steering hose routing.

69 camaro power steering hose routing.

In addition to replacing the power steering hose, it is also important to regularly check the fluid levels in the power steering system and top up as needed. Low fluid levels can lead to air getting into the system, causing a loss of power steering assistance. Regular maintenance of the power steering system will help ensure the longevity and efficiency of the power steering hose and prevent any potential issues from arising.

Made from high-quality materials, it is resistant to harsh weather conditions, ensuring long-term reliability and minimal maintenance Made from high-quality materials, it is resistant to harsh weather conditions, ensuring long-term reliability and minimal maintenance

Made from high-quality materials, it is resistant to harsh weather conditions, ensuring long-term reliability and minimal maintenance Made from high-quality materials, it is resistant to harsh weather conditions, ensuring long-term reliability and minimal maintenance ac flex pipe. Its resistance to corrosion ensures that it maintains its integrity over extended periods, reducing the risk of leaks and electrical shorts.

ac flex pipe. Its resistance to corrosion ensures that it maintains its integrity over extended periods, reducing the risk of leaks and electrical shorts.In addition to their durability and flexibility, Gates power steering hoses are also designed to provide a leak-free seal. Leaks in the power steering system can lead to a loss of power steering fluid, which can cause steering difficulties and potential damage to the power steering pump. With Gates power steering hoses, drivers can have peace of mind knowing that their power steering system is protected from leaks.

7. Once you have confirmed that the new power steering hose is in good condition, carefully connect it to the power steering pump and the steering gear, securing it in place with hose clamps or fittings.

It is also important to ensure that the brake line is properly installed and secured to prevent it from coming loose during operation It is also important to ensure that the brake line is properly installed and secured to prevent it from coming loose during operation

It is also important to ensure that the brake line is properly installed and secured to prevent it from coming loose during operation It is also important to ensure that the brake line is properly installed and secured to prevent it from coming loose during operation brake line from caliper.

brake line from caliper. They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer

They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer They typically feature a multi-layer construction, with inner and outer layers of silicone sandwiching a reinforcement layer silicone power steering hose. This reinforcement, often made of wire, provides additional strength and prevents hose collapse under pressure. The silicone outer layer is usually resistant to oil and fluid contamination, ensuring the hose remains functional even when exposed to various automotive fluids.

silicone power steering hose. This reinforcement, often made of wire, provides additional strength and prevents hose collapse under pressure. The silicone outer layer is usually resistant to oil and fluid contamination, ensuring the hose remains functional even when exposed to various automotive fluids. Regular maintenance, including visual inspections and timely repairs, is vital to catch any potential issues before they escalate into major problems Regular maintenance, including visual inspections and timely repairs, is vital to catch any potential issues before they escalate into major problems

Regular maintenance, including visual inspections and timely repairs, is vital to catch any potential issues before they escalate into major problems Regular maintenance, including visual inspections and timely repairs, is vital to catch any potential issues before they escalate into major problems 2006 honda accord power steering hose.

2006 honda accord power steering hose.

marine power steering hose. Regularly inspecting the hose for signs of wear and tear, such as cracks, leaks, or bulges, can help prevent potential issues before they arise. Additionally, flushing the power steering fluid regularly and replacing it as needed can help maintain the health of the hose and the entire steering system.

marine power steering hose. Regularly inspecting the hose for signs of wear and tear, such as cracks, leaks, or bulges, can help prevent potential issues before they arise. Additionally, flushing the power steering fluid regularly and replacing it as needed can help maintain the health of the hose and the entire steering system. A sudden failure could cause the steering to lock up, making it impossible to control the vehicle, especially in emergency situations A sudden failure could cause the steering to lock up, making it impossible to control the vehicle, especially in emergency situations

A sudden failure could cause the steering to lock up, making it impossible to control the vehicle, especially in emergency situations A sudden failure could cause the steering to lock up, making it impossible to control the vehicle, especially in emergency situations mercedes power steering hose.

mercedes power steering hose.