...

2025-08-15 22:07

2391

...

2025-08-15 21:57

2817

...

2025-08-15 21:27

357

...

2025-08-15 21:15

96

...

2025-08-15 20:39

2308

...

2025-08-15 20:14

62

- Металлообработка При обработке металлов и других материалов с использованием различных пневматических машин.

...

2025-08-15 19:59

2729

...

2025-08-15 19:57

1944

...

2025-08-15 19:43

2342

...

2025-08-15 19:40

397

- Choosing the Right Pump for Flue Gas Desulphurisation

- Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

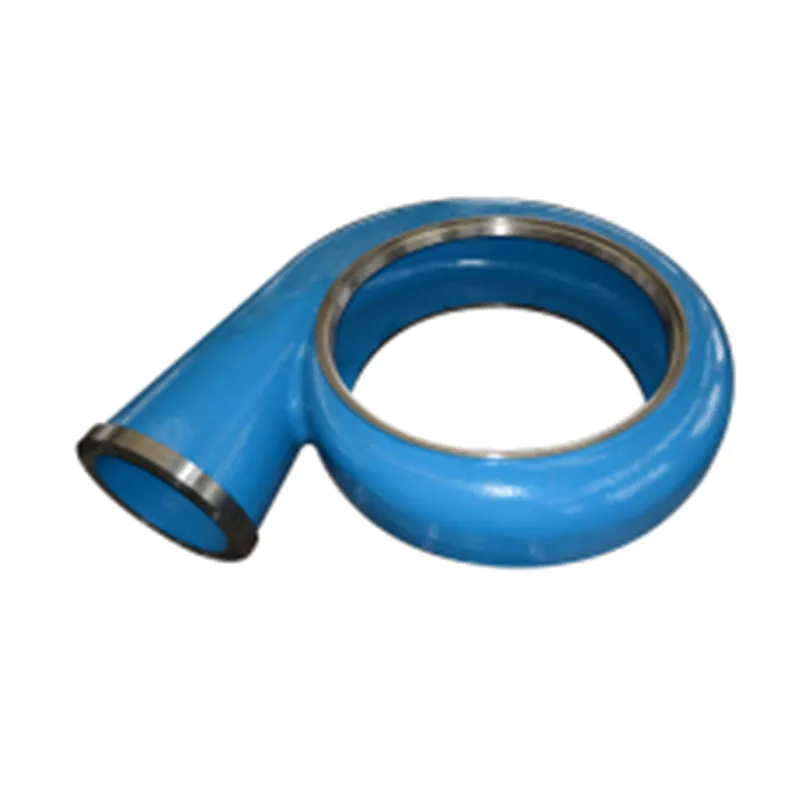

- WY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

- Slurry Pump

- The terms flushing and quench, often seem to be confused or misused when discussing seal support schemes for , slurry pumps, . As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

- >Slurry Pump vs Mud Pump

- Slurry Pump

- Rubber Lined Slurry Pump

- Two types of slurry are found in these industries.

- If you want to know more information about the best slurry pumps wholesale, welcome to >contact us today or request a quote.

- It is important that the pump you choose has components that will not wear out from abrasive slurries.

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

- There is a better way to pump sewage, overflows and other collected dirty water around the plant.

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

- Another way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

- Dredge Pump

- With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

- Submersible Slurry Pump

- 2. All have vertical pumps and horizontal pumps and can convey slurry.

- Dredge Pump

- - Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

- >Slurry Pump

- The Company Adopts Advanced Computer Aided Engineering Software

- The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

- Aier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

- Other manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

- >Dredge Pump

- The construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

- The solution is to choose a >heavy duty slurry pump and, just as importantly, to use a custom built unit with replaceable parts. At Aier Machinery, building your custom slurry pump is one of our areas of expertise. We design your slurry pump to your specifications and application.

- Slurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

- One problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

- Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

- How does a dredge pump work?

- Slurry Pump

- What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. >Slurry pumps are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

- These mud pumps can pump not only sand, but also more mud. They are very effective in pumping all forms of mud, gravel, concrete, slurry, slush, etc.

- >Slurry Pump VS Mud Pump

- One of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

- - Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

- Low slurry flow rates

- A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

- The Difference Between Flushing And Quenching in Slurry Pump Seals

- Choosing the Right Pump for Flue Gas Desulphurisation

- Some models can generate discharge pressures up to 260 ft. (80 m).

- Depending on the abrasive nature of the slurry, it is important to select the ideal seal. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. Vortex pumps use patented seal technology that utilizes a double mechanical seal setup and a separate seal flushing system. This allows the sealing surface to be kept cool at all times without causing the slurry to overheat the seal and crack the surface.

- BCT Ceramic Slurry Pumps

- It is important that the pump you choose has components that will not wear out from abrasive slurries.

- Rubber lined pumps offer many advantages

- - transport solids hydraulically