- In conclusion, LS1 spark plug wires play a crucial role in the performance and reliability of an LS1 engine. Choosing high-quality wires and ensuring proper installation and maintenance are essential for optimal engine performance. By investing in quality spark plug wires and taking care of them properly, LS1 owners can enjoy a smooth-running engine with maximum power and efficiency.

Car Engine Head Gasket: Importance in Engine Functionality

For more detailed information, please see the following:

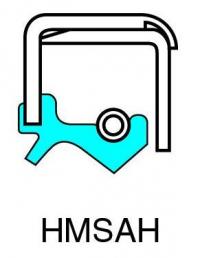

Names and functions of seal componentsLift off the cover. It may need a gentle sideways tap to free it.

- The integration of E6RTC and Spark offers several benefits for businesses

The other way oil seals work is by stopping outboard materials that can damage the machine or contaminate its lubricant. The outboard materials that the oil seal will need to stop depend on the application. However, the most common kinds are dirt, moisture, and the particles produced during manufacturing.

Oil seals are an essential component of many industrial machines and equipment. They play a crucial role in preventing oil leaks, protecting bearings and other crucial parts from contamination, and ensuring the overall smooth operation of the machinery. One popular and widely-used size of oil seal is the 75x100x10 model.

-15 °C to + 180 °C

- 4. Replace the spark plug according to the manufacturer's recommended schedule, typically every 10,000-20,000 miles, or sooner if you notice any signs of a malfunctioning spark plug.

The pulley is kept from turning on the crankshaft by a key fitting into grooves on the crankshaft and pulley.

- Proper maintenance of spark plugs is also vital. Regular checks and replacements, as recommended by the manufacturer, can ensure optimal engine performance. Worn or dirty spark plugs can lead to misfires, reduced fuel efficiency, and even engine damage. Symptoms of worn spark plugs include rough idling, difficulty starting the bike, and decreased acceleration.

PTFE Conventional Motor Oil

Application Industry

Oil seals are also dirt, lip, shaft, and grease seals. They’re simple devices installed in rotary shaft equipment to minimize the risk of lubricant leakage and prevent other foreign substances such as water, dirt, and dust from entering.