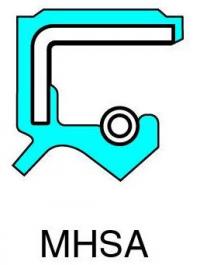

An oil seal normally consists of three basic components: the sealing element, the metal case and the spring. The purpose of the sealing element is to stop the fluid from leaking between the shaft and housing. The metal case will give rigidity and strength to the seal while it is being held in the bore or recessed groove. The garter spring ensures constant pressure and maintains the radial force to the shaft, flattening the sealing edge to a defined width. The garter spring maintains the radial force exerted by the sealing lip around the shaft surface. All materials must be selected depending on the environment in which the oil seal will function.

- Overall, the F7TC Spark Plug represents a major advancement in the field of engine technology. Its superior performance, durability, environmental friendliness, and cost-effectiveness make it an attractive option for both consumers and manufacturers alike. As the automotive industry continues to evolve, the F7TC Spark Plug is sure to play a key role in shaping the future of driving.

- Metric oil seals are an essential component in machinery and equipment to prevent leakage of oil and other liquids. These seals are commonly used in automotive, aerospace, industrial, and manufacturing applications to ensure smooth and efficient operations.

Out of all of the elastomers, silicone offers you the widest range of working temperature ranges. Renowned for its flexibility and low compression set capabilities, silicone is the optimal choice for o rings and other moulded seals.

- A7TC spark plugs are a type of high-performance spark plug designed to work with both petrol and diesel engines. They feature a unique electrode design that enhances the spark's energy and duration, resulting in more efficient combustion and improved engine performance. A7TC spark plugs are known for their long life and resistance to corrosion, making them a popular choice for both street and off-road vehicles.

The skeleton oil seal structure consists of three parts: the oil seal body, the reinforced skeleton and the self-tightening coil spring. The sealing body is divided into bottom, waist frame oil seal structure diagram, cutting edge and sealing lip according to different parts. Generally, the inner diameter of the skeleton oil seal in the free state is smaller than the shaft diameter, that is, it has a certain interference. Therefore, after the oil seal is installed on the oil seal seat and the shaft, the pressure of the oil seal edge and the contraction force of the self-tightening coil spring will produce a certain radial tightening force on the shaft. After a period of operation, the pressure will rapidly decrease or even disappear. , Therefore, adding a spring can compensate for the self-tightening force of the oil seal at any time.

m20 valve cover gasket.

Construction of an Oil Seal

Stijn de Cnop

Lubricant

Before fitting the oil seal, it is essential to check that the oil seal, shaft and bore are clean and undamaged. The surfaces the oil seal will come into contact with must be free of sharp points or burrs. The sealing lip is fragile, so even minimal damage can cause a leak. It is also important that the shaft and bore are correctly finished.

The group of oil seals used in dynamic applications include radial shaft seals that seal a rotating shaft around its circumference. They are also known as lip seals, but in this blog we will use the term oil seals.

Car Head Gasket: Essential Component in Engine Sealing

Auto parts oil seals play a crucial role in the proper functioning and maintenance of vehicle systems. These seals are designed to prevent the leakage of lubricating oil and the ingress of contaminants, ensuring the integrity and efficiency of various components within the vehicle. From wheel hub oil seals to steering oil seals, these components are essential for the smooth operation and longevity of automotive systems.

Auto gaskets are crucial components in vehicle systems, serving to create a secure seal between mating surfaces to prevent fluid or gas leakage. These gaskets are used in various automotive applications, including engines, transmissions, and exhaust systems. High-quality auto gaskets are essential for maintaining the integrity and efficiency of vehicle systems, contributing to optimal performance and reliability.

power steering oil seal.

How to Choose the Right Oil Seal

5. TYPES OF FLUID: Numerous oil seals can interact with oils, fuels, grease, water and more. However, know exactly what type of fluid the rotary shaft seal will be in contact with will ensure the longevity of the seal and the machinery.

This is particularly beneficial for vehicles operating in urban environments where frequent stop-and-go driving can strain engine performance This is particularly beneficial for vehicles operating in urban environments where frequent stop-and-go driving can strain engine performance

This is particularly beneficial for vehicles operating in urban environments where frequent stop-and-go driving can strain engine performance This is particularly beneficial for vehicles operating in urban environments where frequent stop-and-go driving can strain engine performance oil seal turbo.

oil seal turbo.