- Data Logging:This function is reserved for advanced control boxes or panels. With this cutting-edge device, you can input certain information to help you manage or troubleshoot your connected appliance.

pvc electrical insulation. It can be easily molded into various shapes and sizes to fit different wire configurations. This versatility makes PVC insulation adaptable to diverse electrical applications, from household wiring to industrial machinery.

pvc electrical insulation. It can be easily molded into various shapes and sizes to fit different wire configurations. This versatility makes PVC insulation adaptable to diverse electrical applications, from household wiring to industrial machinery.

130c linerless rubber splicing tape. Whether used for electrical insulation, sealing, or bonding, the 130c% linerless rubber splicing tape provides a reliable and long-lasting solution.

3. Flexibility and Adaptability Butyl rubber is inherently flexible, allowing it to be easily installed and conformed to various roofing shapes and structures. This adaptability makes butyl rubber sheets suitable for both flat and sloped roofs, providing a reliable solution for architects and builders working on diverse projects.

In various industries and environments, maintaining safety and organization is paramount. One of the simplest yet most effective solutions for enhancing safety and efficiency is the use of floor marking tape. Specifically, red and white floor marking tape serves a crucial role in guiding behavior, preventing accidents, and ensuring compliance with safety regulations. This article explores its applications, benefits, and importance across different sectors.

3. Measure and Cut Measure the length of the gap that needs sealing and cut the butyl weather stripping accordingly. It’s advisable to cut a little longer than necessary, allowing for a snug fit.

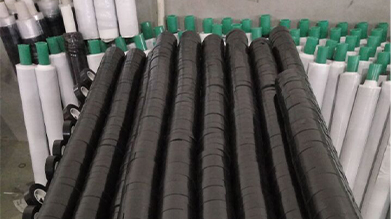

black electrical insulation tape. Electricians often use it to color-code different circuits or mark specific wires for future reference, enhancing the overall clarity and efficiency of electrical systems. The strong adhesive backing guarantees that once applied, the tape will stay in place, surviving vibrations and environmental changes without peeling off or losing stickiness.

black electrical insulation tape. Electricians often use it to color-code different circuits or mark specific wires for future reference, enhancing the overall clarity and efficiency of electrical systems. The strong adhesive backing guarantees that once applied, the tape will stay in place, surviving vibrations and environmental changes without peeling off or losing stickiness.PVC tape is one variety of electrical tape, as mentioned above. Functional and durable, PVC (polyvinyl chloride) tape is considered a ‘balanced’ plastic tape and is used in similar situations to vinyl electrical tape. However, PVC tape copes well with environmental factors and is often used for outdoor applications.

At its simplest, a control box is an enclosure that houses electrical components such as switches, knobs, and controls. It’s the central point from which electrical circuits are managed, distributed, and protected. Think of it as the brain of an operation where the electrical nervous system can be coordinated with precision. In industrial applications, control boxes oversee the process of heavy machinery. In a residential context, they might regulate heating and cooling systems. The primary functions of a control box include:

Self-fusing rubber tape is a simple yet powerful solution that addresses various repair and maintenance needs. Its unique properties, including self-adhesion, flexibility, resistance to extreme temperatures, and waterproofing capabilities, make it an indispensable resource for both professionals and DIY enthusiasts. Whether you are looking to fix a leaky pipe, insulate electrical wires, or bundle tools, self-fusing rubber tape offers an efficient and reliable option that stands the test of time. With its growing popularity, this remarkable tape is poised to become a staple in households and industries alike, proving that sometimes the simplest solutions can provide the most significant benefits.

Hot-melt rubber

What is Polyethylene Tape used for?

high tension insulation tape. For instance, green indicates earth or ground, blue denotes neutral, while brown and black are commonly used for live conductors. This color coding not only enhances safety by visually differentiating wires but also streamlines installation and troubleshooting processes.

high tension insulation tape. For instance, green indicates earth or ground, blue denotes neutral, while brown and black are commonly used for live conductors. This color coding not only enhances safety by visually differentiating wires but also streamlines installation and troubleshooting processes.Red and white floor marking tape is a small but impactful tool in enhancing workplace safety and efficiency. Its bright colors provide immediate visual cues that aid in the prevention of accidents and the promotion of organized environments. Whether in warehouses, manufacturing plants, retail spaces, or healthcare facilities, the strategic use of this tape can significantly improve safety protocols and operational flow.

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

The most common type of electrical insulation tape used in the home, vinyl tape is used for insulation, protection from moisture, and repairing minor nicks and cuts.

In today's world of DIY projects, home repairs, and industrial applications, self-fusing rubber tape has emerged as a vital tool due to its unique properties and versatility. This innovative tape has gained attention for its ability to create strong, long-lasting bonds without the need for adhesives, making it a go-to solution for various applications.

Generally speaking, manufacturers use three different adhesive types in combination with the backing material to produce a final “tape” product. Though these adhesive types can be subdivided into subgroups, the main categories are as follows: